Intelligent overhead wire online grease applying device

An overhead wire, oiling technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of inability to meet corrosion resistance requirements, difficult manual coating, and high viscosity of anti-corrosion grease to improve coating efficiency. , Simple structure, the effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

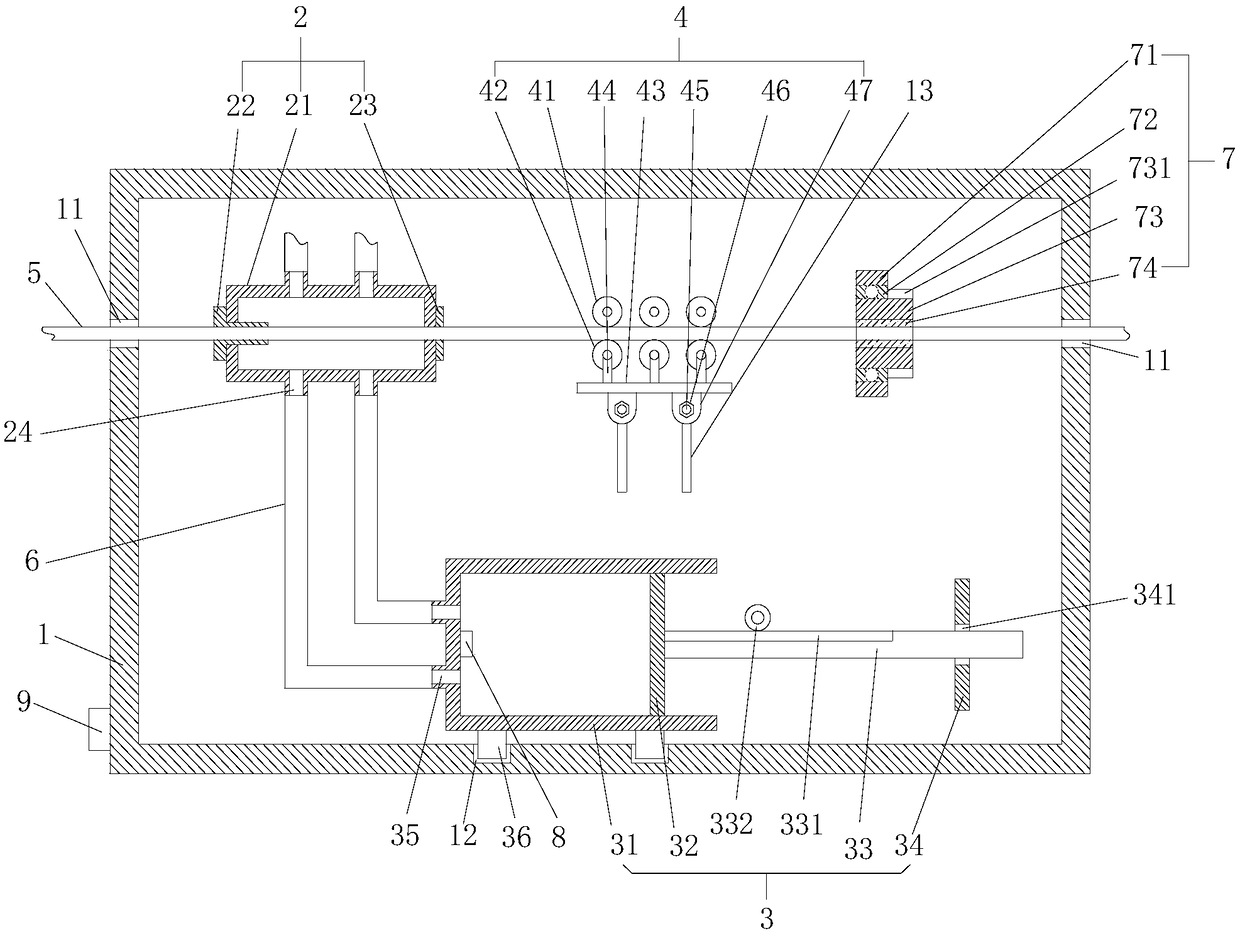

[0043] See Figure 1 to Figure 4 , the intelligent online oiling equipment for overhead wires in this embodiment includes a box body 1 and an oiling device 2 , an oil supply device 3 and a transmission device 4 arranged in the box body 1 .

[0044] The box body 1 in this embodiment is preferably a box with a cover plate, and the cover plate and the box body are hingedly connected, similar to a briefcase. The opposite sides of casing 1 are provided with threading holes 11 for wires to pass through. When the cover plate of casing 1 is opened, half of threading holes 11 are on the casing, and the other half are on the cover plate. Once installed, it cannot be disassembled, so this structure is convenient for clamping the wire.

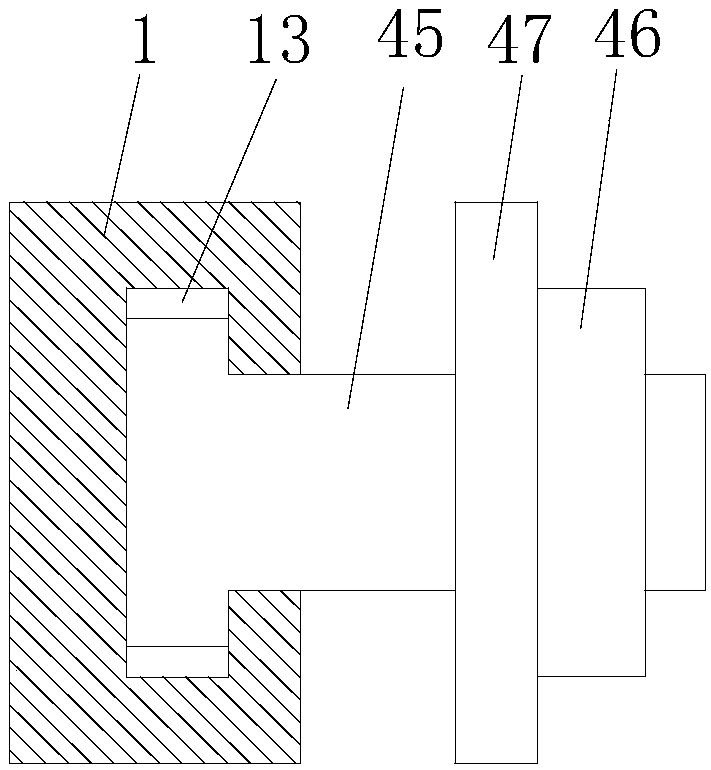

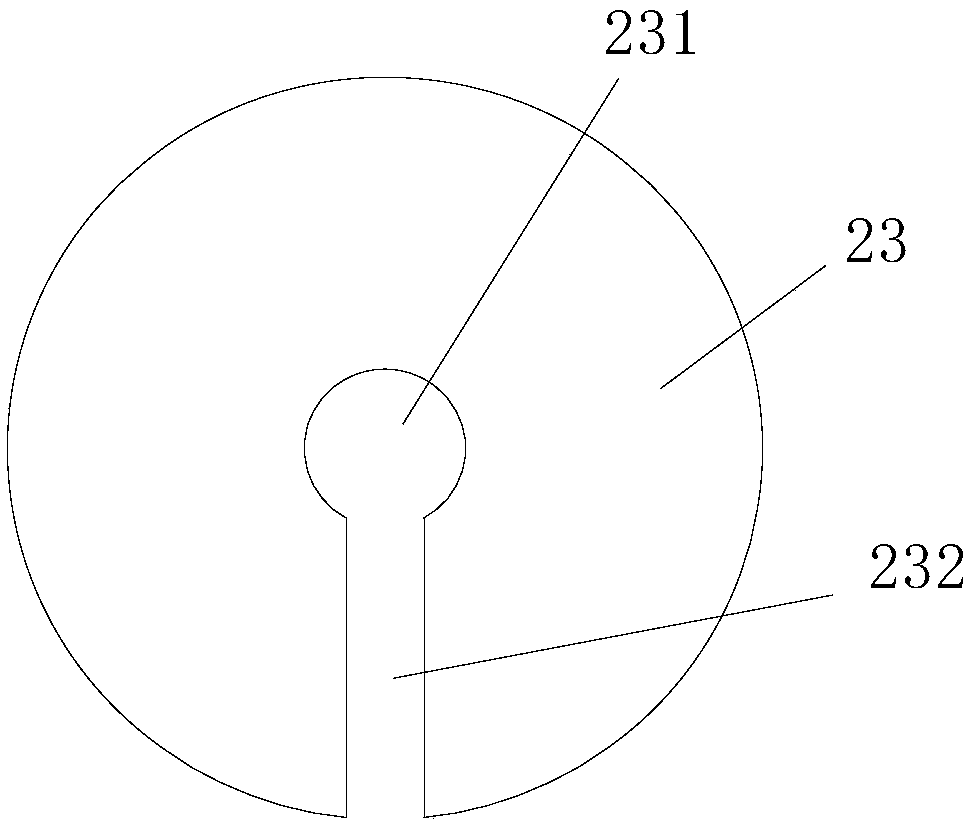

[0045] The oiling device 2 is used to coat the surface of the wire 5 with grease; the oiling device 2 in the present embodiment includes an oil storage tank 21 and a nylon sleeve 22 and an elastic sheet 23 arranged on the oil storage tank 21, and one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com