Cap assembly for cylindrical battery and cylindrical secondary battery

A technology for cylindrical batteries and caps, which is applied to small-sized batteries/battery packs, battery pack parts, battery boxes/coats, etc., which can solve the problems of increasing the space occupied by batteries, increasing the internal resistance of batteries, and low combination efficiency, etc. Problems, to achieve the effect of increasing the battery footprint, saving space, and increasing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

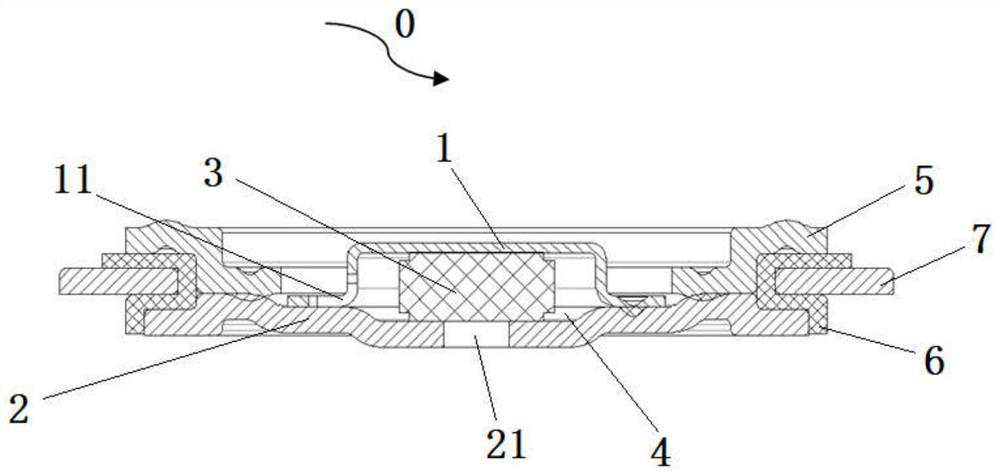

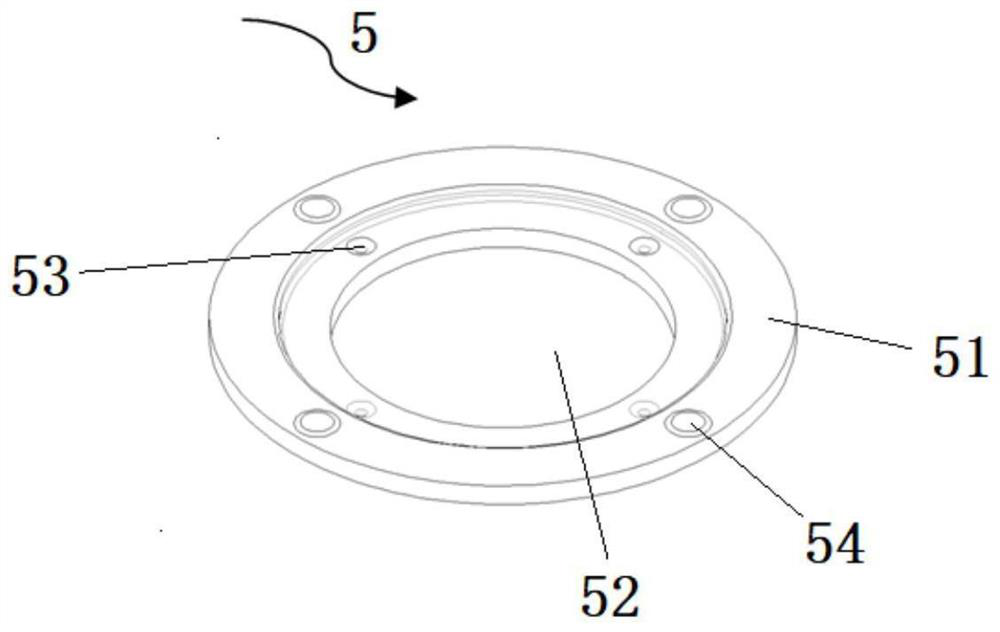

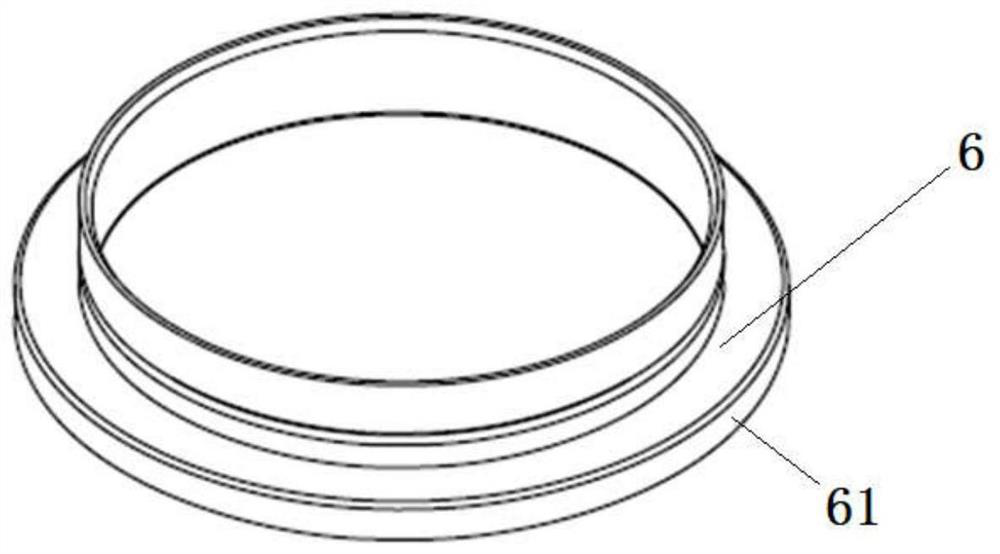

[0017] A cylindrical battery cap combination 0, such as figure 1 As shown, it includes an upper cap 1, a lower cover 2, an explosion-proof ball 3 and a positive connection part 5. The upper cap 1 and the lower cover 2 are tightly combined, and the side of the upper cap 1 is provided with at least one exhaust hole 11, and the lower cover 2 is provided with an explosion-proof hole 21 in the central position, and an accommodation space 4 is formed between the upper cap 1 and the lower cover 2, and the explosion-proof ball 3 is placed in the accommodation space 4, such as figure 2 As shown, the positive connection part 5 is a U-shaped circular concave platform structure in a side view. The top periphery of the positive connection part 5 is vertically provided with an outwardly protruding skirt 51, and the bottom of the positive connection part 5 is provided with an upper cap hole. 52, the bottom of the positive connecting part 5 is provided with several outwardly protruding first...

Embodiment 2

[0020] A cylindrical secondary battery such as Figure 4 As shown, including steel case 8, electric core 9 and electrolyte (not shown in the figure), electric core 9 is placed in steel case 8 and injects electrolyte in steel case 8, also comprises the cylinder as described in embodiment 1 Cap assembly 0 for a shaped battery, the steel case 8 is not provided with a rolling groove, the positive pole end 91 of the battery cell 9 is welded together with the lower cover of the cap assembly 0, and the periphery of the negative connecting ring of the cap assembly 0 is connected to the top of the steel case 8 Weld together to complete the steel shell 8 seals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com