Two-stage energy storage motor structure with large starting torque

A technology of starting torque and motor structure, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as energy waste and waste, and achieve the effect of making up for insufficient power, reducing collisions, and improving operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

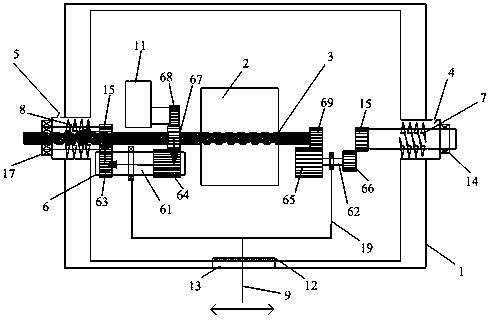

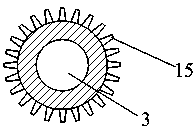

[0029] Such as figure 1As shown, a motor structure with two-stage energy storage and high starting torque includes a casing 1, which is a high-strength casing to ensure the stability of the motor and the output shaft. The middle part of the casing 1 is provided with a motor 2, the two ends of the motor 2 are provided with an output shaft 3, the two sides of the casing 1 are respectively provided with an air inlet 4 and an air outlet 5, and the air inlet 4 and the air outlet 5 are respectively provided with There is a solenoid valve, and the solenoid valve is used to control the opening and closing of the air inlet 4 and the air outlet 5, so as to realize the flow of air in the casing 1. The air inlet 4 is provided with a turbofan I7, and the air outlet 5 is provided with a turbofan II8. The turbofan I7 can accelerate the air flow at the air inlet 4, and the turbofan II8 can accelerate the air flow at the air outlet. The turbofan I7 and / or turbofan II8 are sleeved on the outpu...

Embodiment 2

[0033] Such as figure 1 As shown, a motor structure with two-stage energy storage and high starting torque, the transmission device 6 includes a transmission shaft I61 and a transmission shaft II62, the two ends of the transmission shaft I61 are respectively fixed with a gear I63 and a gear II64, and the gear I63 and the The ends of the turbofan II8 are matched, and the gear II64 is meshed with the middle part of the output shaft 3 to realize the transmission connection between the transmission shaft I61 and the output shaft 3 . The two ends of the transmission shaft II62 are respectively fixed with a gear III65 and a gear IV66, and the gear III65 meshes with the end of the output shaft 3 to realize the transmission connection between the transmission shaft II62 and the output shaft. Gear IV66 cooperates with the end of turbofan I7. The length of the gear II64 and the gear III65 is relatively large, and both the gear II64 and the gear III65 are in a constant mesh state with t...

Embodiment 3

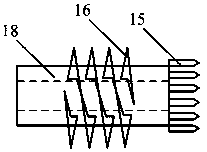

[0044] A motor structure with two-stage energy storage and high starting torque, such as Figure 5 As shown, the transmission device 6 includes a transmission sleeve I611 and a transmission sleeve II612, and the transmission sleeve I611 and the transmission sleeve II612 are respectively sleeved on the output shaft 3 at both ends of the motor 2, as Figure 7 As shown, one end of the transmission sleeve I611 and the transmission sleeve II612 is provided with a fixed bearing I615, and the other end is provided with a rubber pad I613, and the ends of the turbofan I7 and turbofan II8 are fixed with a rubber pad II614 matching the rubber pad I613 ,Such as Image 6As shown, the rubber pad I613 and the rubber pad II614 are high wear-resistant rubber pads, and the surfaces of the rubber pad I613 and the rubber pad II614 are raised to increase the friction force of the interaction between the two, and the two contact each other to generate friction, thereby Realize the transmission of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com