Synchronous rail driving system and annular production line

A technology of drive system and synchronous track, which is applied in the field of transmission, can solve the problems of low synchronization accuracy and achieve the effect of saving production cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

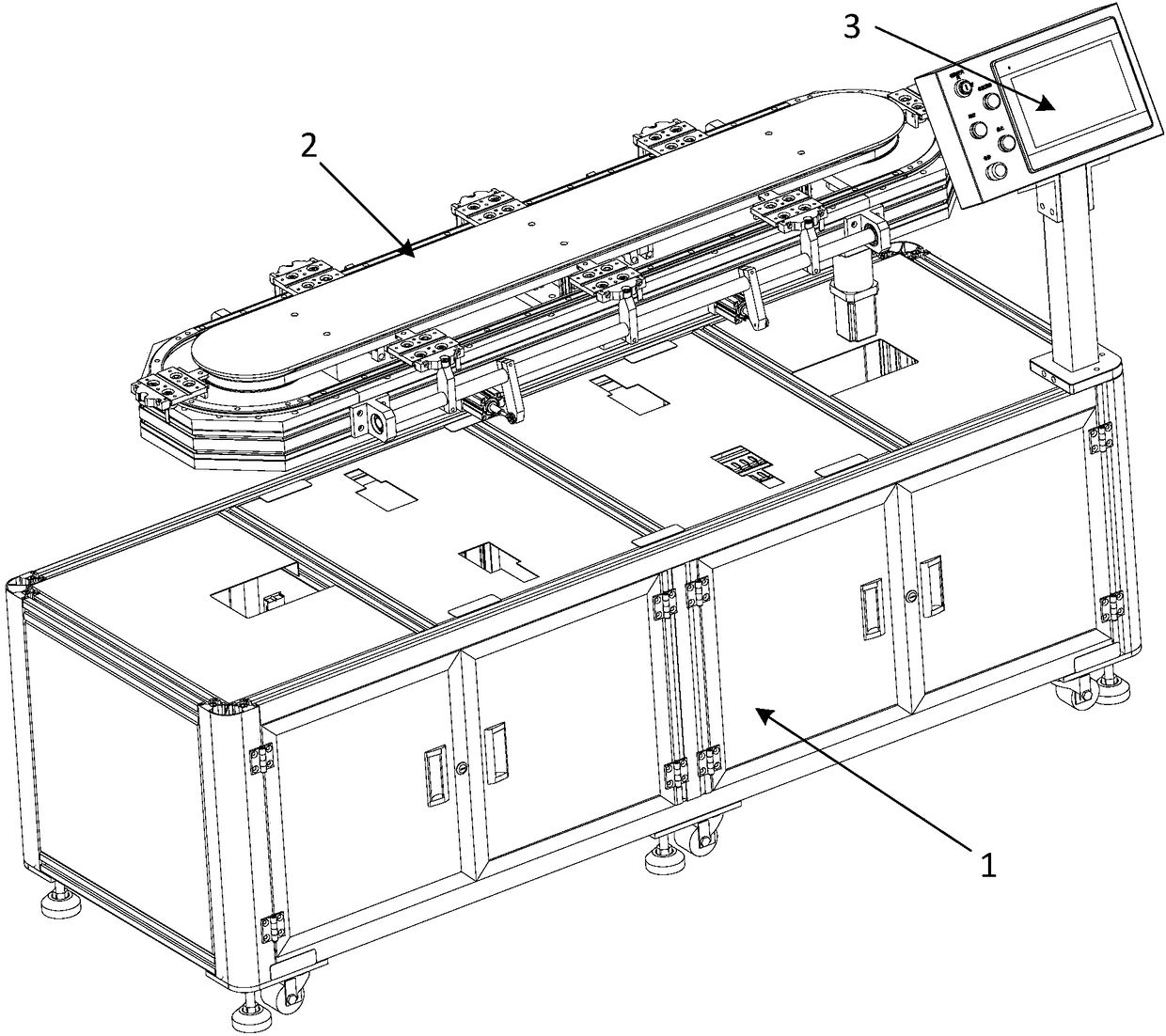

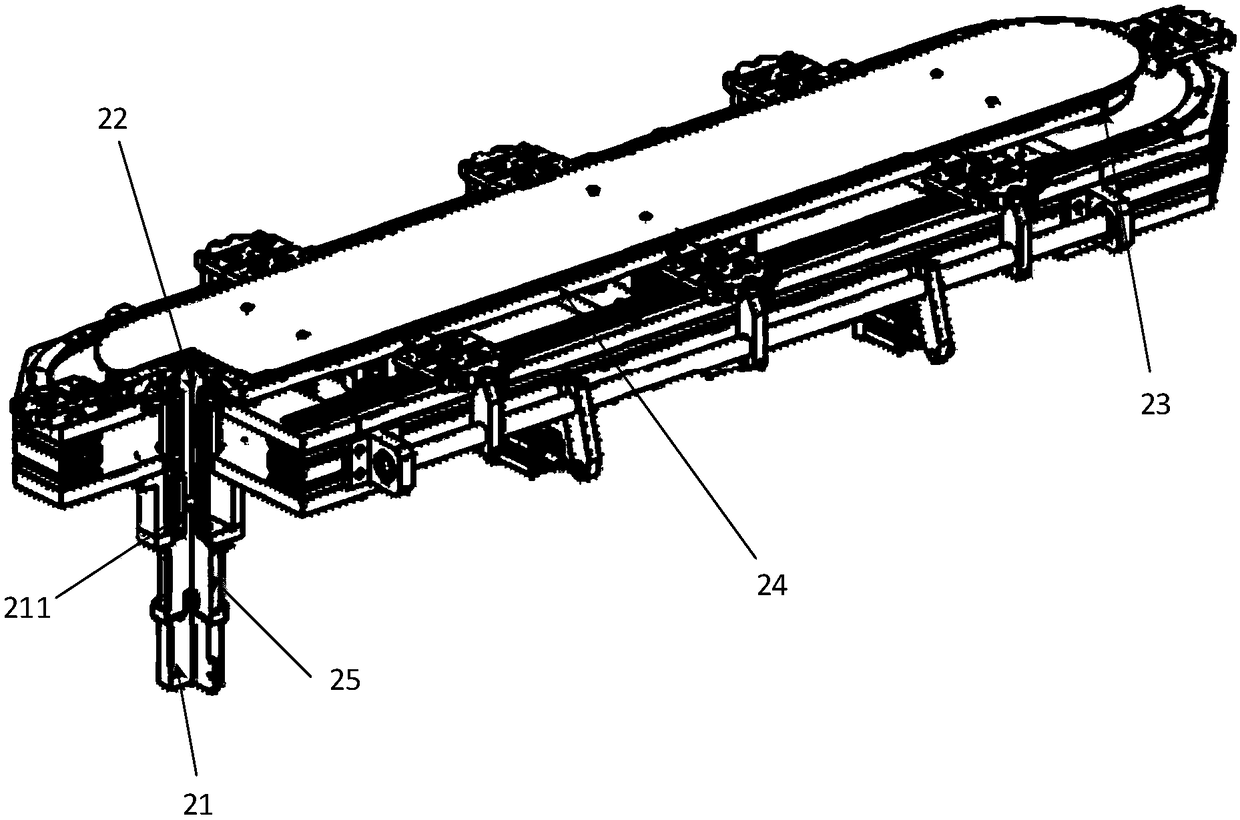

[0035] refer to figure 1 and figure 2 , figure 1 Shown is the overall structure of the synchronous rail drive system provided by the embodiment of the present invention, the synchronous rail drive system includes a cabinet 1 and a table assembly 2, and the table assembly 2 is arranged above the cabinet 1, wherein an engineering control machine is arranged in the cabinet 1 And control bus, the engineering control machine is provided with PLC (Programmable Logic Controller, Programmable Logic Controller), and PLC controls other devices through the control bus; Further, the synchronous track driving system also includes a control panel 3, a control panel 3. Set on the cabinet 1, it can be located at any corner of the cabinet 1. There are multiple control buttons on the control panel 3. Through the control buttons, the synchronous track drive system can be started, shut down, emergency stop, safety lock, etc. At the same time, the system parameters can be set through the visual...

Embodiment 2

[0051] An embodiment of the present invention provides a circular production line. The circular production line includes the synchronous track drive system in the above embodiment. The circular assembly line using the above synchronous track drive system can realize efficient and accurate automatic assembly, and meet the frequent start-up and Stagnation.

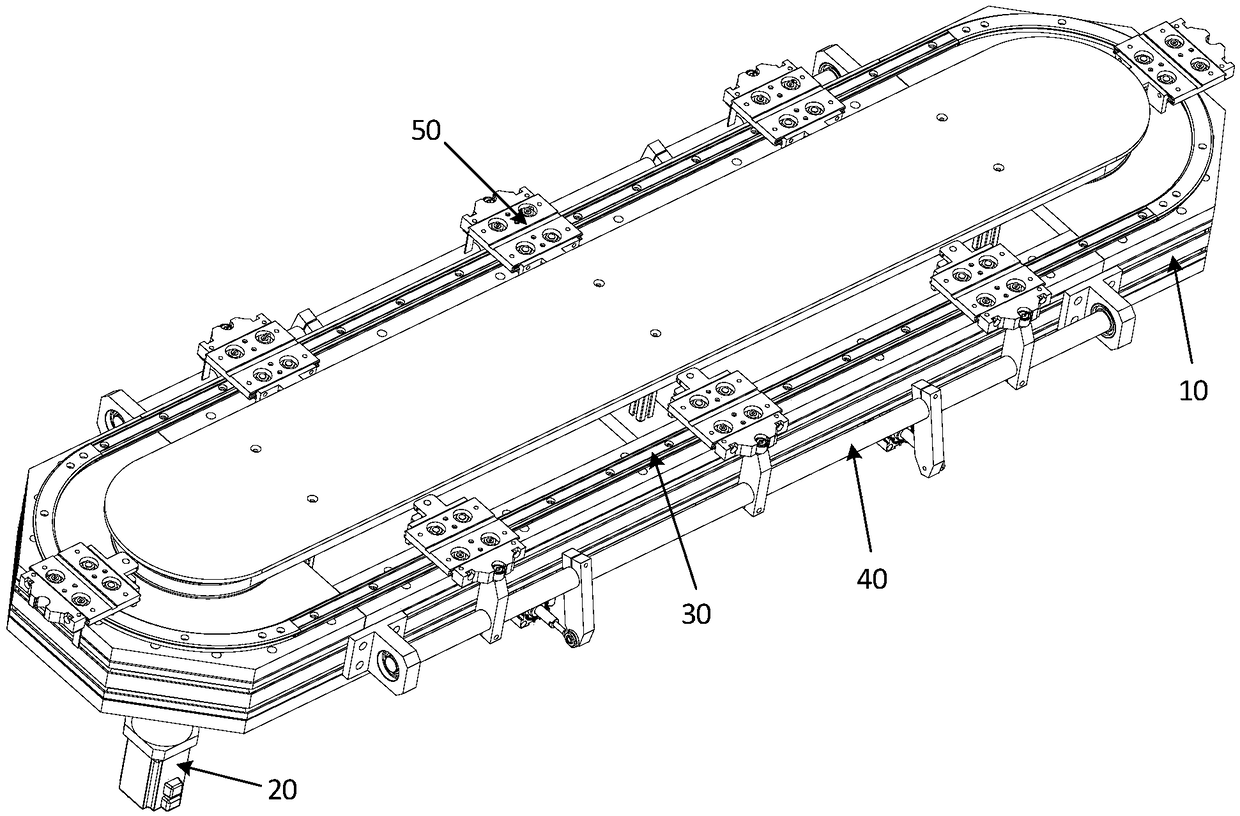

[0052] The synchronous track drive system can be combined with multiple manipulators to form a micro-miniature fully integrated automatic production line to realize the output from the input of multiple accessories to the output of finished products. Different assembly equipment can be configured according to needs to meet the diversification of production. For example, in this embodiment, set There are 6 processing stations, see Figure 4 , each processing station corresponds to a slider assembly 50, a fixture is installed on the slider assembly 50, the product is placed on the fixture, and different actions are completed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com