Construction device for underground anti-seepage curtain and construction method

A technology for construction devices and anti-seepage curtains, applied in protection devices, drilling equipment and methods, earthwork drilling and mining, etc., can solve problems such as restrictions on popularization, and achieve the effects of avoiding complex processes, simple equipment processes, and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

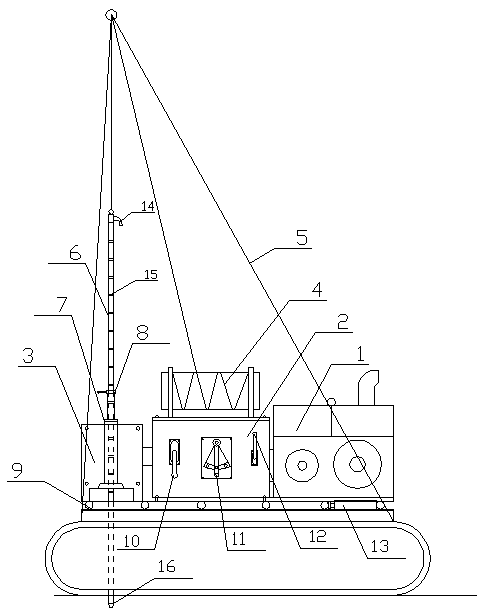

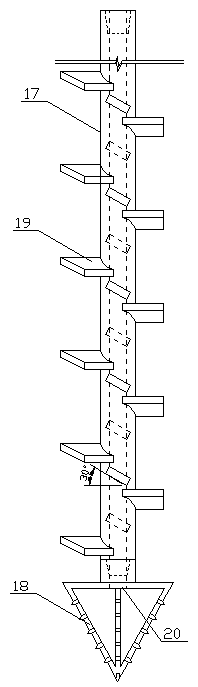

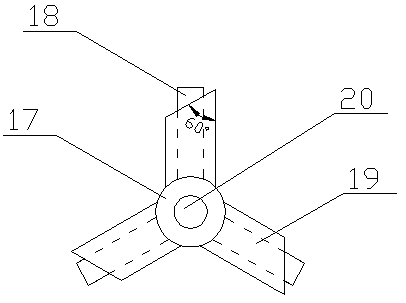

[0059] A construction device for an underground anti-seepage curtain, which consists of: a sawing rig and a sawing drill rod 17, the main components of the sawing rig are: a diesel engine and a hydraulic pump 1, a gearbox 2, a power head 3, a winch 4, a drilling frame 5, Active drill pipe 6, drill pipe lifting hydraulic cylinder 7, active drill pipe lifting buckle 8, drill chassis slide 9, active drill pipe lifting control handle 10, active drill pipe speed control handle 11, active drill pipe rotation clutch 12, saw The chassis of the drilling rig slides back and forth to drive the hydraulic cylinder 13. The active drill pipe is a hollow drill pipe with a regular hexagonal cross-sectional shape. Its upper end is connected to the water injection joint 14 through a screw. The threaded button 16 can be connected with the saw drill rod 17, the active drill rod lifting buckle drill rod lifting hydraulic cylinder is fixed and sleeved on the active drill rod, the active drill rod lif...

Embodiment 2

[0061] According to the construction device of the underground anti-seepage curtain described in Embodiment 1, the lower end of the saw drill rod is provided with a slurry outlet 20 and a drill bit 19 is installed thereon.

Embodiment 3

[0063] According to the construction device of the underground anti-seepage curtain described in Embodiment 1, the sawtooth is 3-4 rows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com