Far-near light lens assembly device with function of preventing chromatic dispersion

A technology of far and near light and lens group, applied in signal devices, lighting devices, components of lighting devices, etc., can solve the problems of difficult installation, increase in price, high cost, etc., and achieve simple structure, prevention of dispersion, and processing and manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

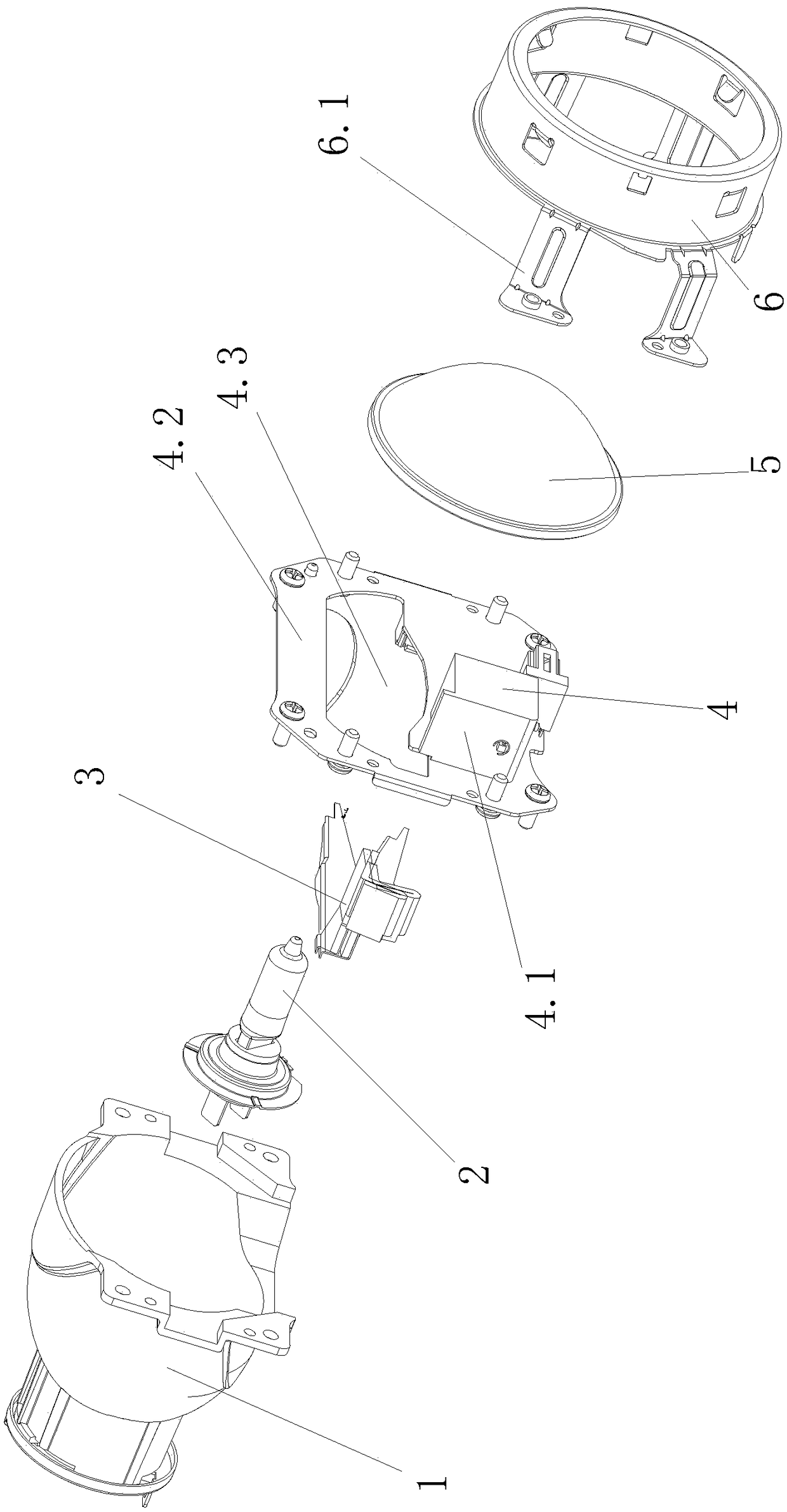

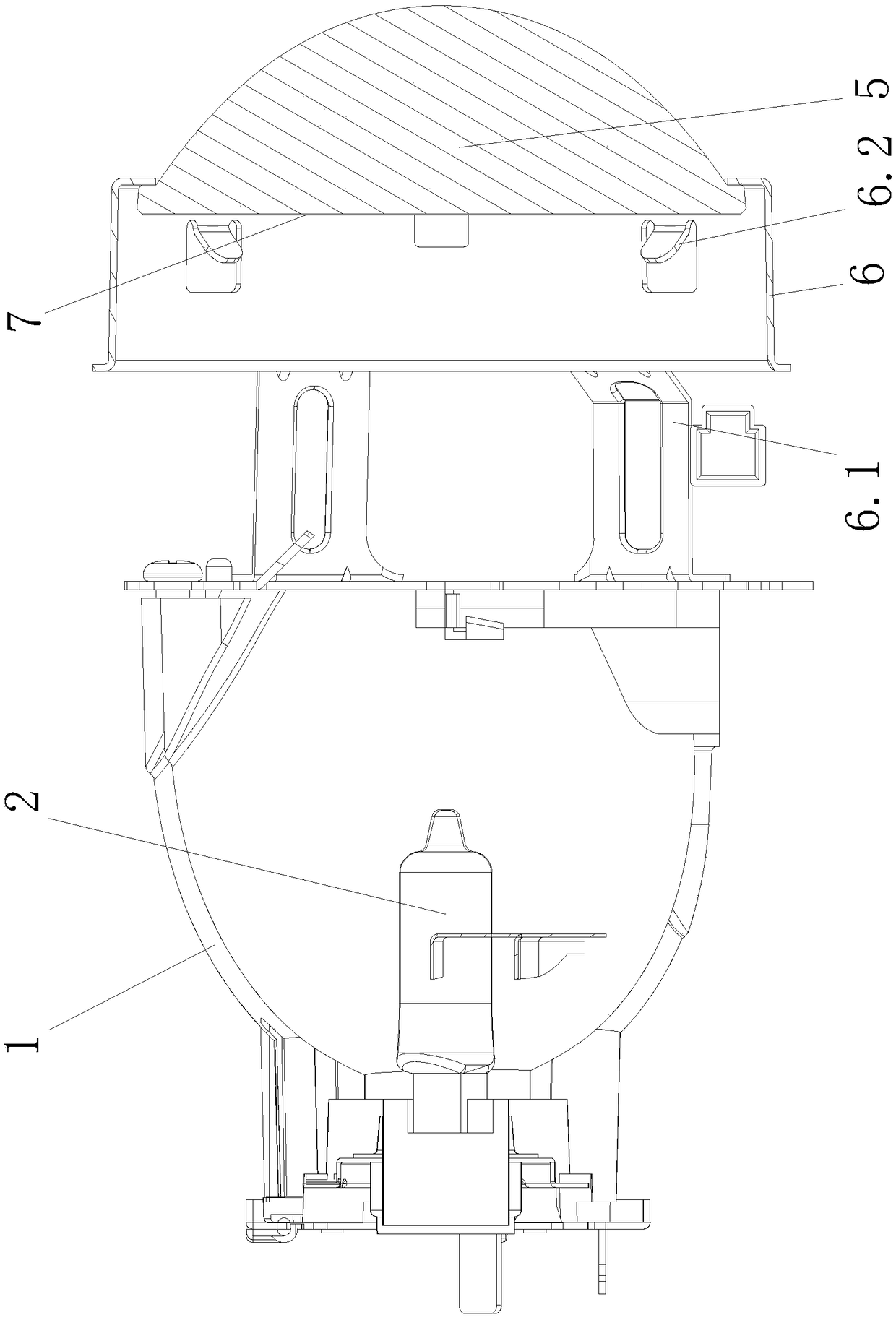

[0016] Such as figure 1 , figure 2 As shown, the present invention includes a lamp body reflective bowl 1, a luminous light source 2, a light blocking device 3, a solenoid valve mechanism 4, a lens 5, and a lens cover 6. The solenoid valve 4.1 on the solenoid valve mechanism 4 is fixed on the solenoid valve mounting plate 4.2, and the solenoid valve mounting plate 4.2 is provided with a through hole 4.3. A cut-off filter film 7 is attached to the inner surface of the lens 5 by electroplating. Wherein, the lens cover 6 is provided with four Z-shaped connecting feet 6.1. Between the reflective bowl 1 of the lamp body and the solenoid valve mounting plate 4.2 and between the reflective bowl 1 of the lamp body and the connecting pin 6.1, all are connected together with bolts. Preferably, the lens cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com