Detonation shock wave bubble rapid dust fall method

A blister and fast technology, applied in the field of blasting, can solve the problems of insufficient uniformity and limited dust reduction effect, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

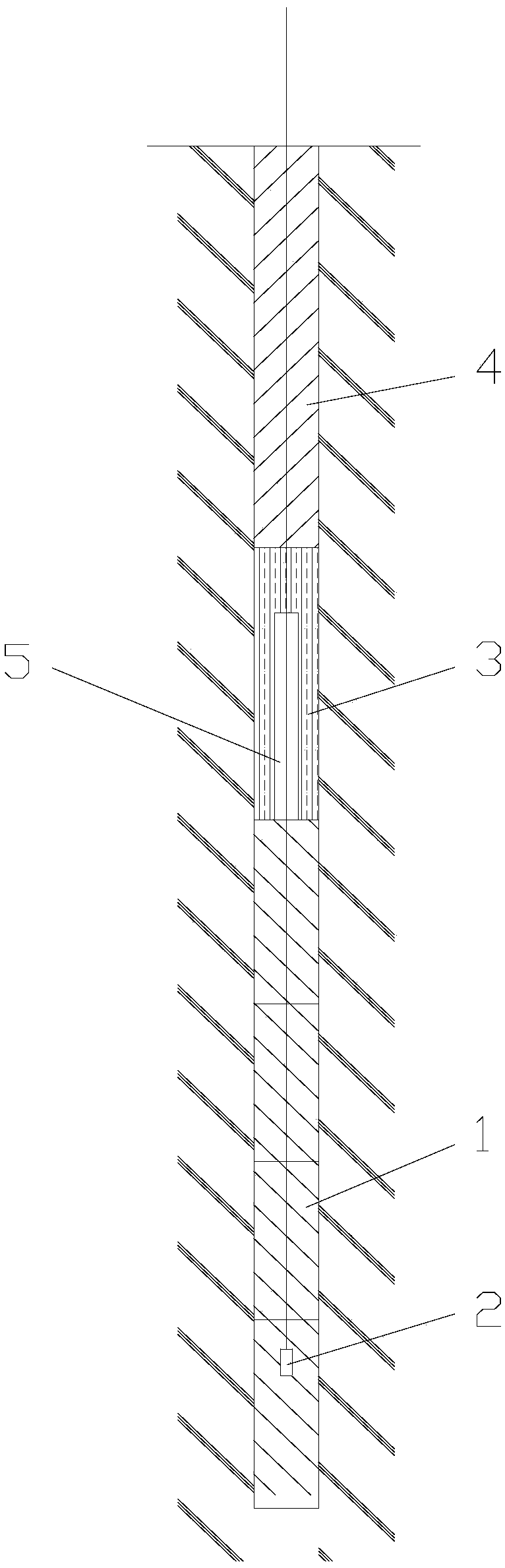

[0018] The present invention will be further described below with reference to the drawings and embodiments.

[0019] As shown in the figure, the blasting shock wave bubble rapid dust reduction method of this embodiment includes the following steps:

[0020] 1) Put water into a water bag, the ratio of the volume of water to the volume of the water bag: 0.6~0.7;

[0021] 2) Put the foaming agent into a water bag, and each liter of water contains 0.2-0.5g foaming agent; the foaming agent is used to generate bubbles and make the generated bubbles relatively stable. There are many types of foaming agents in the prior art. The foaming agent used in this embodiment is Dowfroth 250, which can generate a large number of tiny bubbles.

[0022] 3) Fill the water bag with carbon dioxide gas or carbonic acid at 25°C and seal the water bag. After sealing, the air pressure in the water bag is 0.5~0.6MP;

[0023] 4) Install the water bag 1 on the end of the explosive column 3 in the blasthole, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com