Real-time detection method for wear condition of cross section disc hob of hard rock driving machine

A technology of tunnel boring machine and disc hob, which is applied in the direction of measuring devices and instruments, and can solve the problems of not fully considering the coupling effect of joint inclination angle and joint spacing, lack of rock friction performance, and weakened rock mass bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

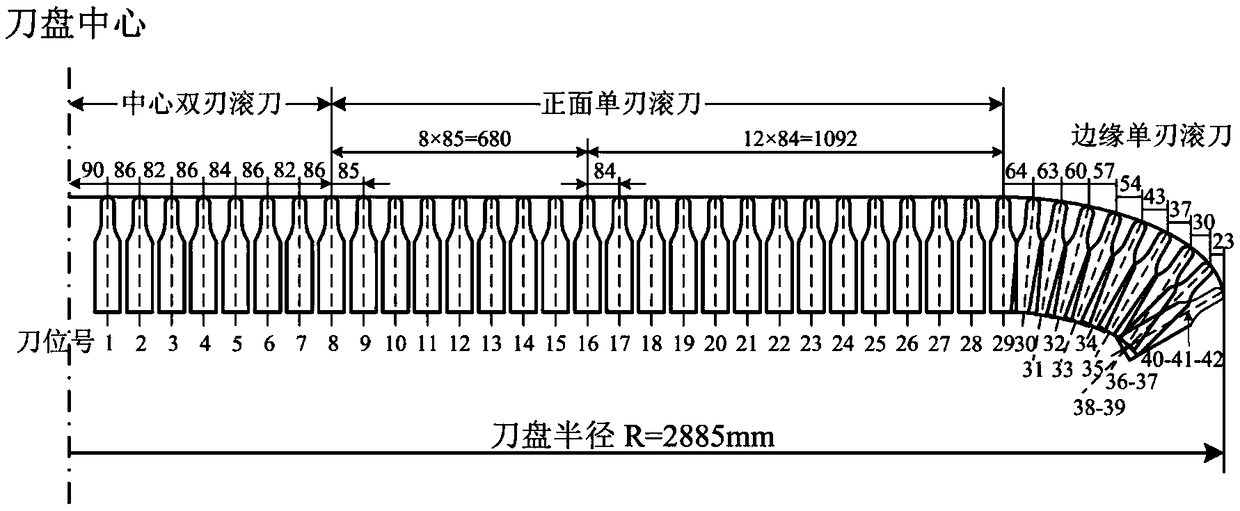

Image

Examples

Embodiment 1

[0079] The method of the present invention will be further described below through specific examples. It should be noted that the scope of protection of the claims of the present invention is not limited by these examples.

[0080] A real-time detection method for the wear condition of the constant section disc hob of the hard rock tunnel boring machine, the specific steps are as follows:

[0081] The first step is to determine the relationship between the cutter head speed, tunneling rate and depth of cut of the hard rock tunnel boring machine:

[0082] The relationship between the cutter head speed, tunneling rate and depth of cut of the hard rock tunnel boring machine is determined by the following formula (1),

[0083]

[0084] In the formula (1): p is the depth of cut of the hard rock tunnel boring machine, that is, the tunneling distance of the hard rock tunnel boring machine per one rotation of the cutterhead, in mm, and v is the tunneling speed of the hard rock tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com