High-temperature and high-pressure composite fretting wear testing device

A fretting wear and test device technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve problems such as large size, deviation of test data, unfavorable operation, etc., to achieve easy operation, avoid interference factors, and ensure verticality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

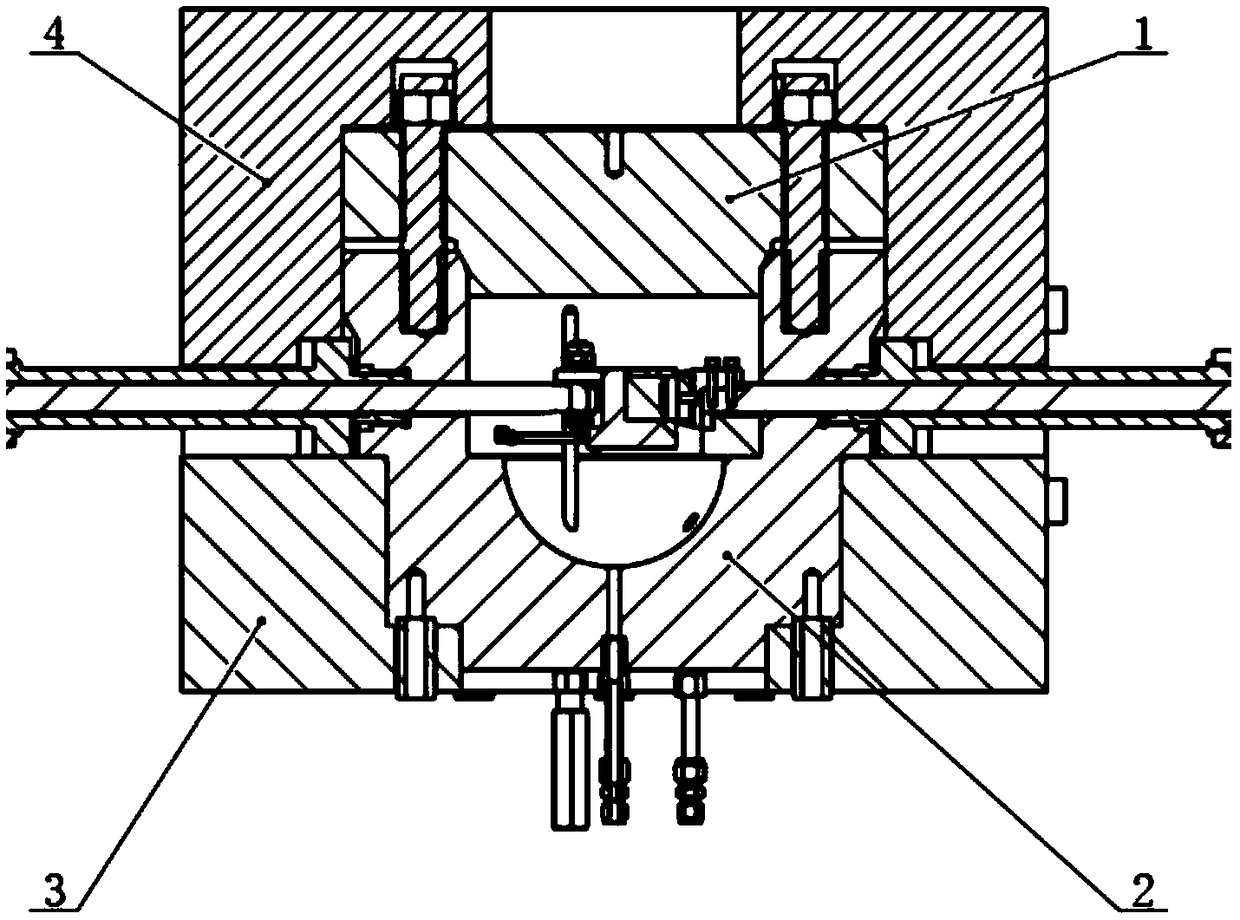

[0047] see figure 1 , a high temperature and high pressure composite fretting wear test device, including an autoclave, a heating furnace, a tangential fixture mounting seat 6, a tangential fretting assembly, an auxiliary support mounting seat 23, and a radial fretting assembly. Wherein, the autoclave is arranged in the heating chamber of the heating furnace, including a kettle body 2 and a kettle cover 1, and the kettle cover 1 is arranged on the upper side of the kettle body 2, and the kettle body 2 and the kettle cover 1 can cooperate to form a Airtight chamber. The heating furnace includes a lower heating furnace 3 and an upper heating furnace 4, and the lower heating furnace 3 and the upper heating furnace 4 cooperate and wrap the autoclave. Through the vertical installation of the autoclave, the kettle body 2 is on the bottom and the kettle cover 1 is on the top, which reduces the volume of the upper part of the autoclave, facilitates operation, and avoids the problem o...

Embodiment 2

[0060] This embodiment is further limited on the basis of Embodiment 1, and other parts are the same as or similar to Embodiment 1, and will not be repeated here.

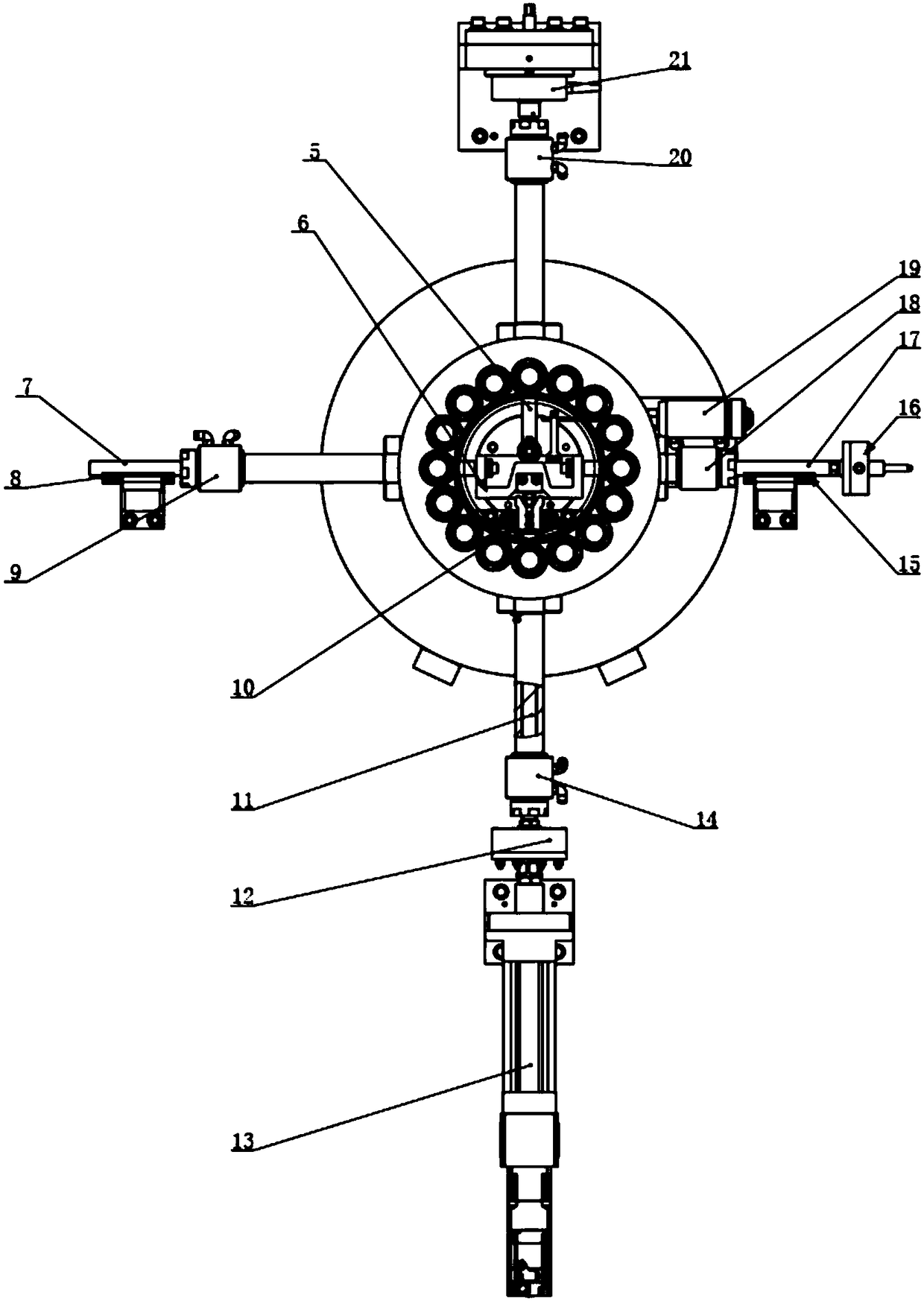

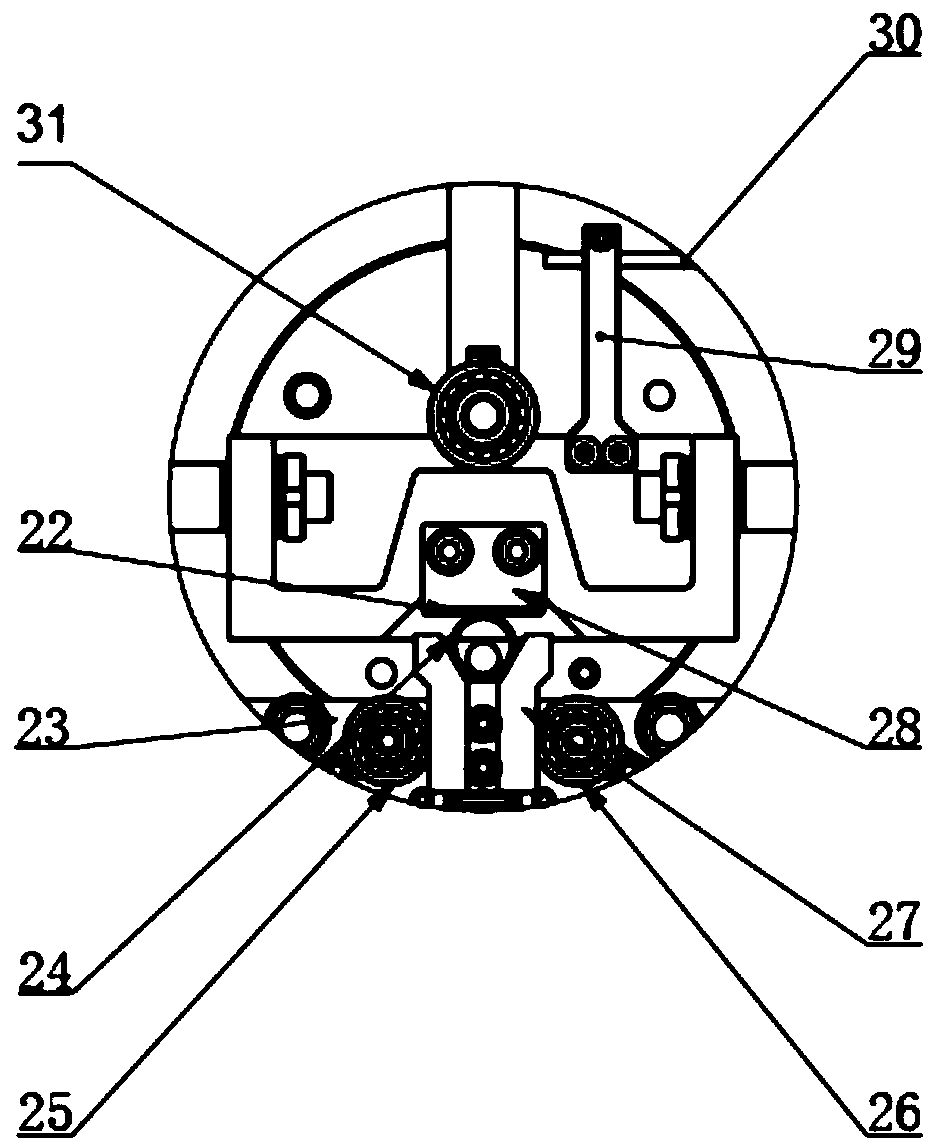

[0061] see figure 2 and image 3 , a high temperature and high pressure compound fretting wear test device, the driving device includes a servo motor and a cam linkage, which converts the rotational motion of the servo motor into a lateral reciprocating motion. The tangential reciprocating motion required for the test can be obtained by adjusting the servo motor and the cam linkage mechanism.

[0062] Further, the first end of the radial loading shaft 11 may also be fixedly connected to one side of the radial clamp 27 .

[0063] Further, the displacement sensor 19 is an LVDT sensor. The LVDT sensor measures the amplitude of the sample in the kettle in real time, and the upper computer collects and records the corresponding data in real time, which can realize the adjustment and control of the amplitude of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com