Storage tank bottom plate active passive sound fusion detection method

A storage tank bottom plate and detection method technology, applied in measuring devices, using acoustic wave emission technology for material analysis, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of inability to obtain dimensions, small detection coverage, and incomplete evaluation results To achieve the effect of improving detection efficiency, improving detection coverage, and comprehensive, intuitive and reliable evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

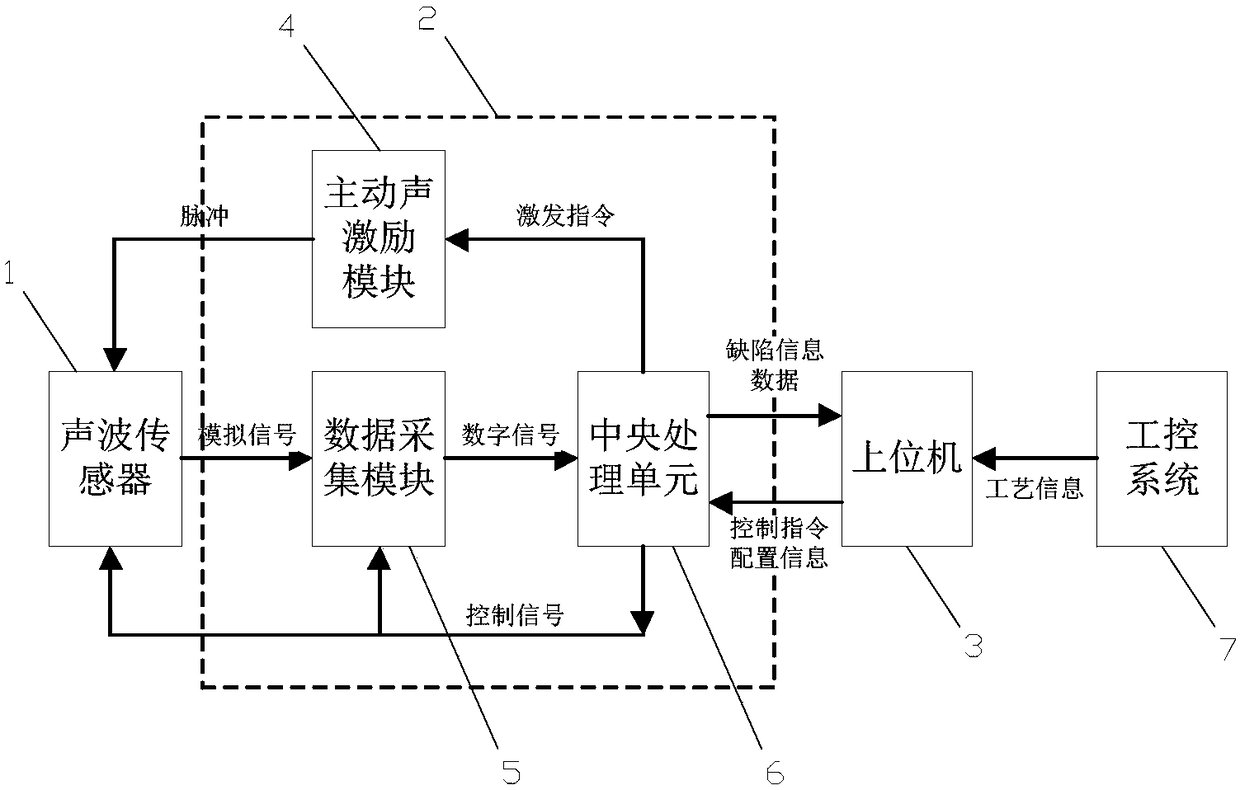

[0043] combine figure 1 As shown, the active and passive acoustic fusion detection system for the bottom plate of the storage tank includes the acoustic wave sensor 1, the acquisition card 2 and the host computer 3; the acoustic wave sensor 1 and the acquisition card 2 are connected by a signal cable, and the acquisition card 2 and the host computer 3 are connected by a high-speed bus .

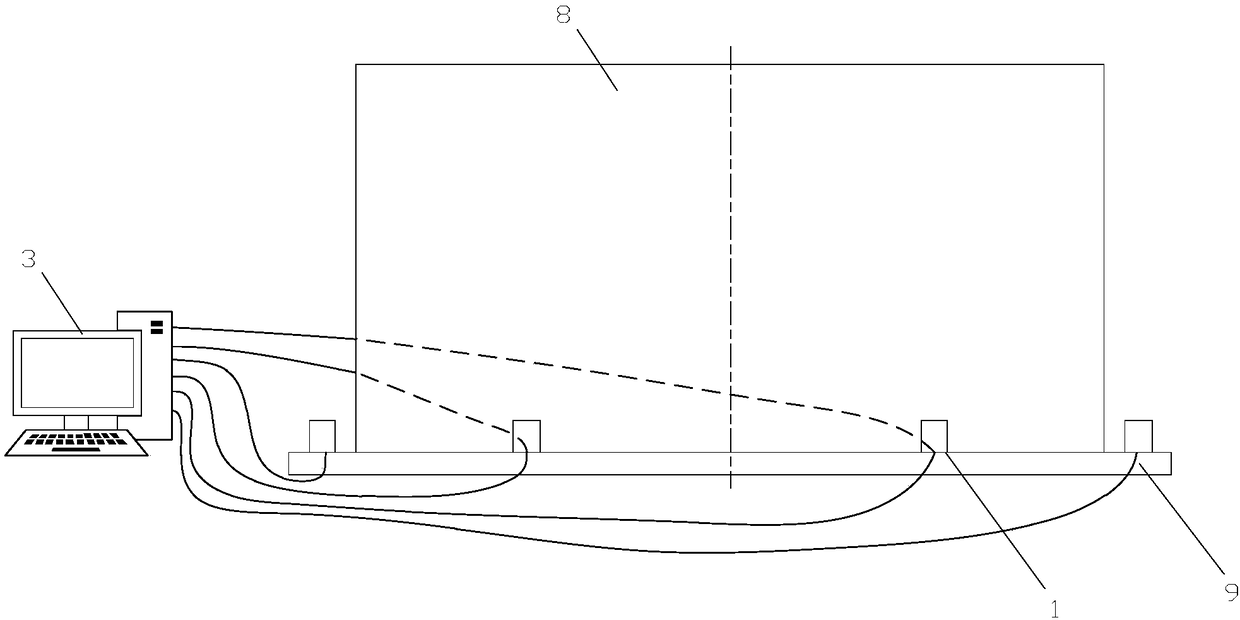

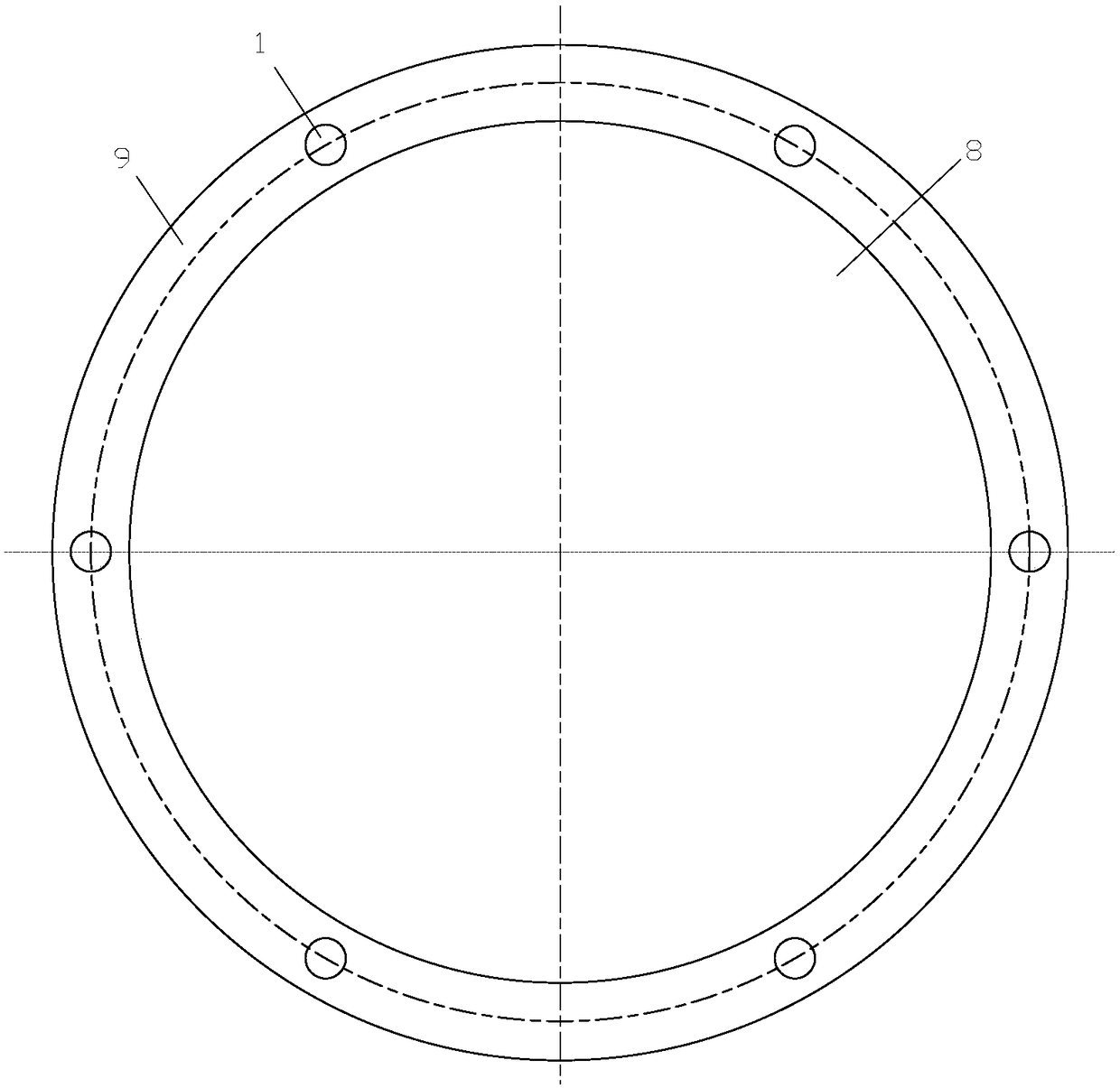

[0044] There are multiple acoustic wave sensors 1 in the present embodiment 1, and each acoustic wave sensor 1 is evenly arranged on the tank bottom edge plate 9 of the storage tank 8, as figure 2 with image 3 shown. The acoustic wave sensor 1 in the first embodiment has both the functions of receiving and emitting acoustic waves.

[0045] By arranging the above-mentioned acoustic wave sensor, active and passive acoustic wave detection can be performed on the defects of the tank bottom.

[0046] The acquisition card 2 is integrated with an active acoustic excitation module 4 , a data ac...

Embodiment 2

[0070] This embodiment 2 describes an active and passive acoustic fusion detection system for the bottom plate of a storage tank. Except for the following technical features that are different from the above-mentioned embodiment 1, other technical features of this embodiment 2 can refer to the above-mentioned embodiment 1.

[0071] Since the number of acoustic wave modes increases with the increase of frequency, using multiple narrow-band excitation signals as the excitation wave can suppress the multi-mode of the excited wave and reduce the complexity of monitoring. In Embodiment 2, the frequency range is 20kHz-500kHz, and the excitation wave in this range attenuates slowly, so this frequency band can be selected as the frequency range of the active acoustic excitation wave.

Embodiment 3

[0073] This embodiment 3 describes an active and passive acoustic fusion detection system for the bottom plate of a storage tank. Except for the following technical features that are different from the above-mentioned embodiment 1, other technical features of this embodiment 3 can be referred to above-mentioned embodiment 1.

[0074] The acoustic wave sensor 1 in Embodiment 3 is connected to the acquisition card 2 through a coaxial cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com