Ice blasting system and method

A cleaning system, water ice technology, applied in the direction of chemical instruments and methods, abrasive jetting machine tools, cleaning methods and appliances, etc., can solve the problems of reducing portability, increasing complexity, size, weight and cost, and achieving effective jetting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Throughout the following description, specific details are set forth in order to provide a thorough understanding to those skilled in the art. However, well known elements may not have been shown or described in detail to avoid unnecessarily obscuring the disclosure. Accordingly, the specification and drawings are to be regarded as illustrative rather than restrictive.

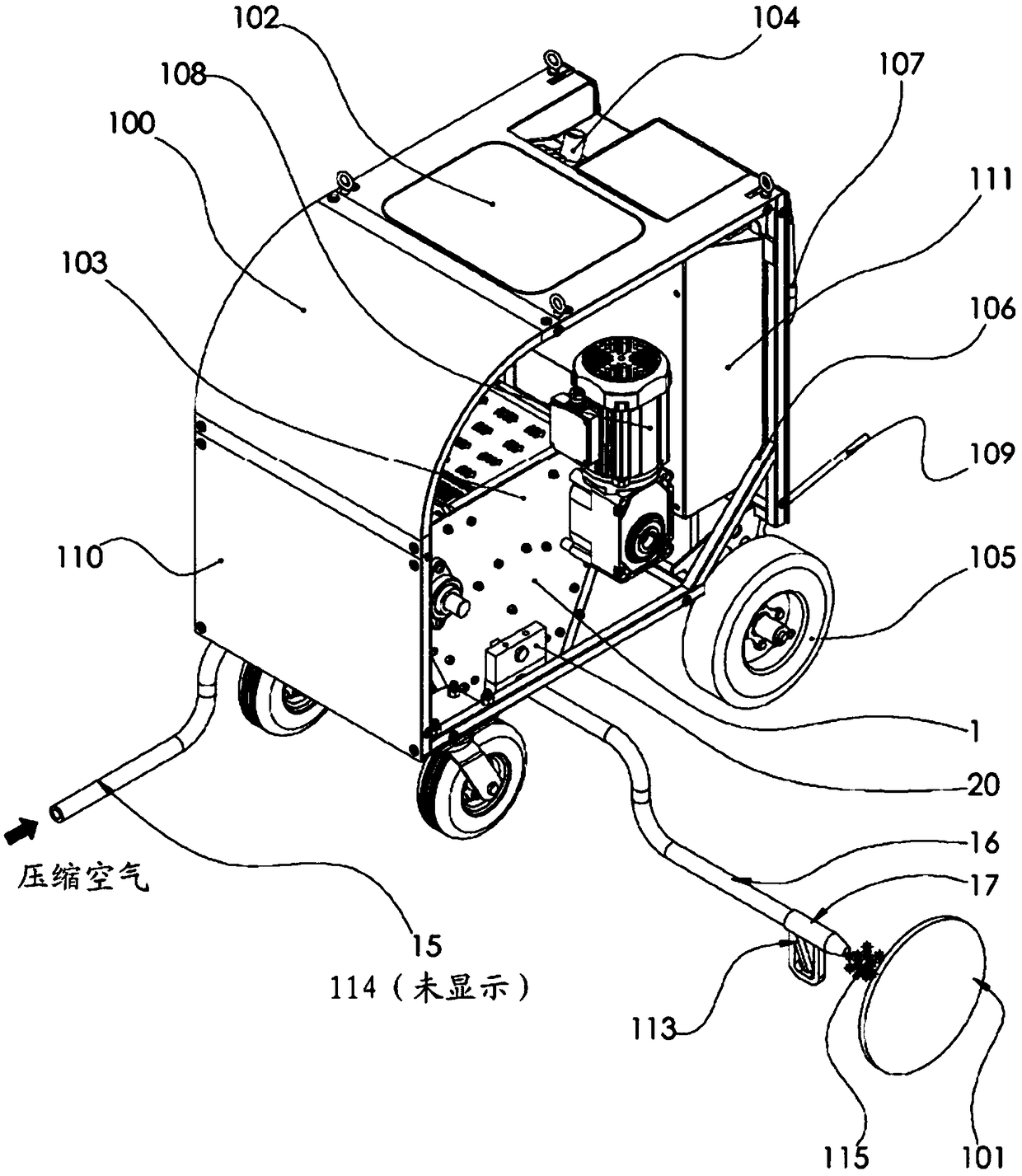

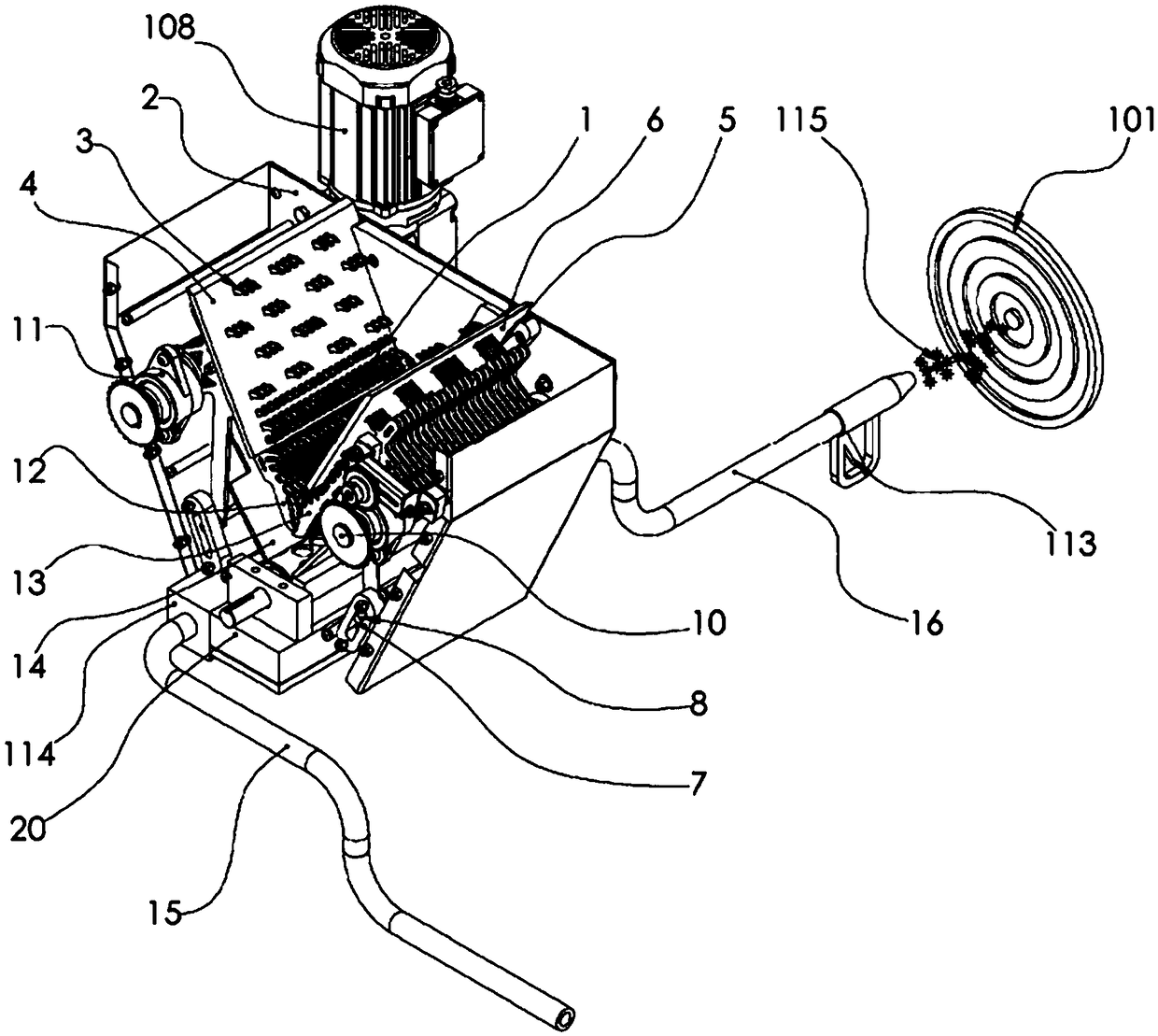

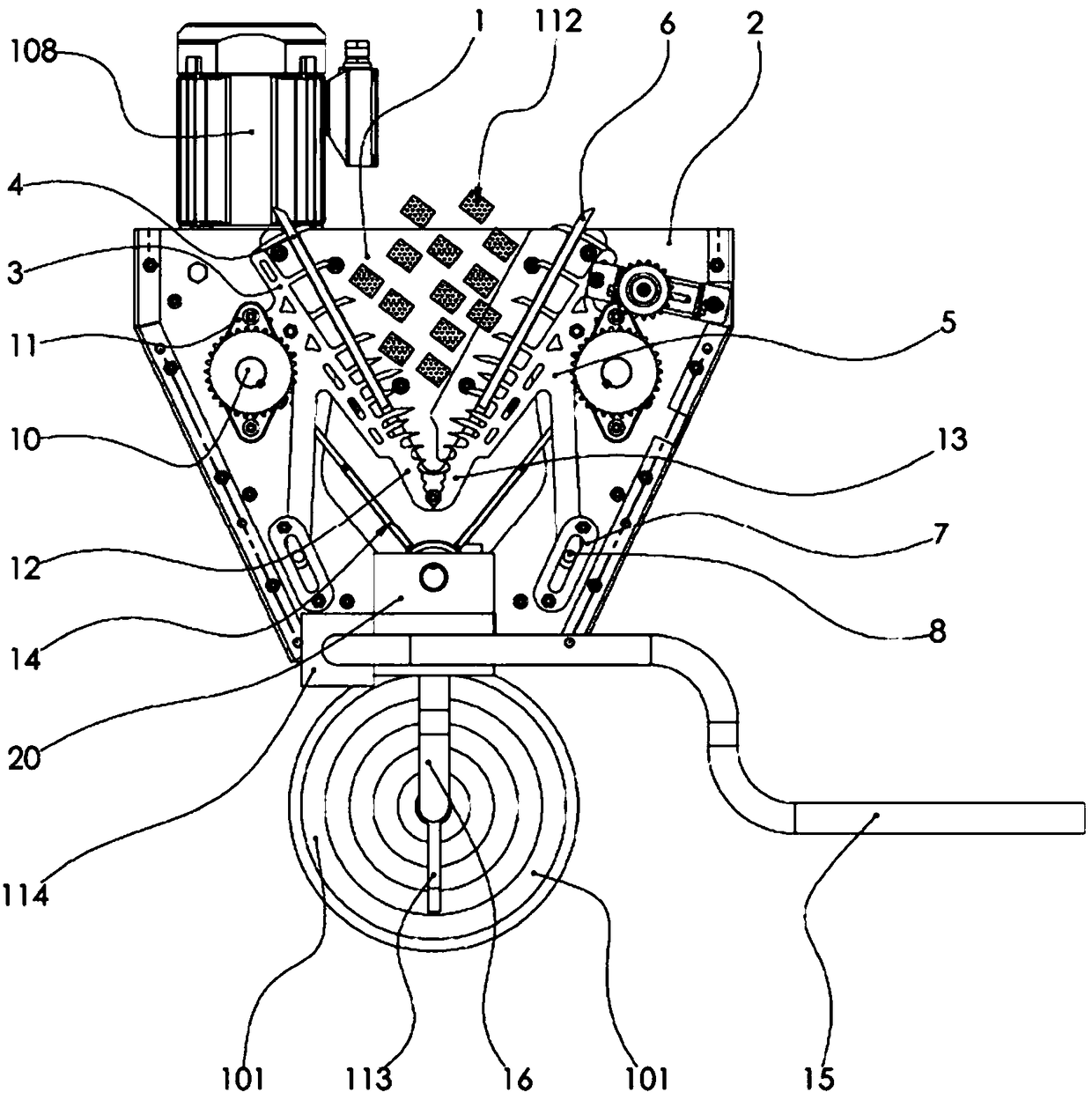

[0041] In general, and by way of introduction and overview, embodiments described in this disclosure relate to an ice blasting system and method in which bulk ice is supplied from an external source rather than produced internally. By eliminating the internal ice maker, the ice blasting system is smaller, lighter, simpler and more portable. Ice blasting systems have a particle sorter (or breaker) that uses a claw-like mechanism with two sets of opposing ice-breaking teeth to crush or break up bulk ice. The sorted particles are mixed into a stream of pressurized fluidizing agent, such as compressed air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com