Geosynthetic clay liner with electrically conductive properties

A geosynthetic, clay technology, used in geotextiles, conductive materials, conductive materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

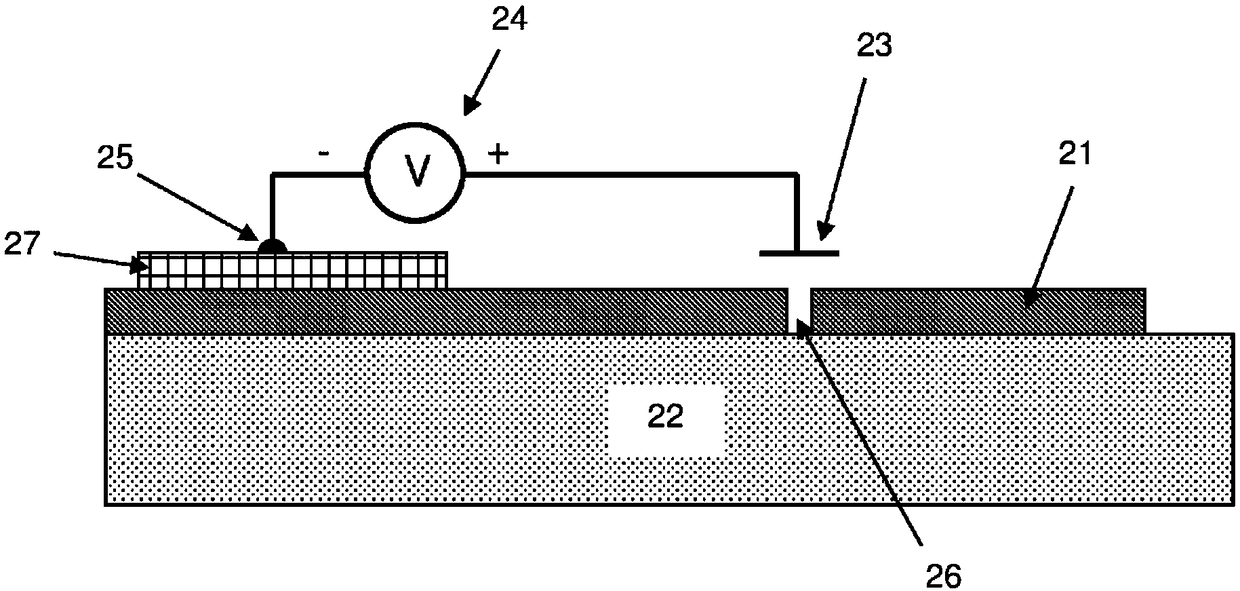

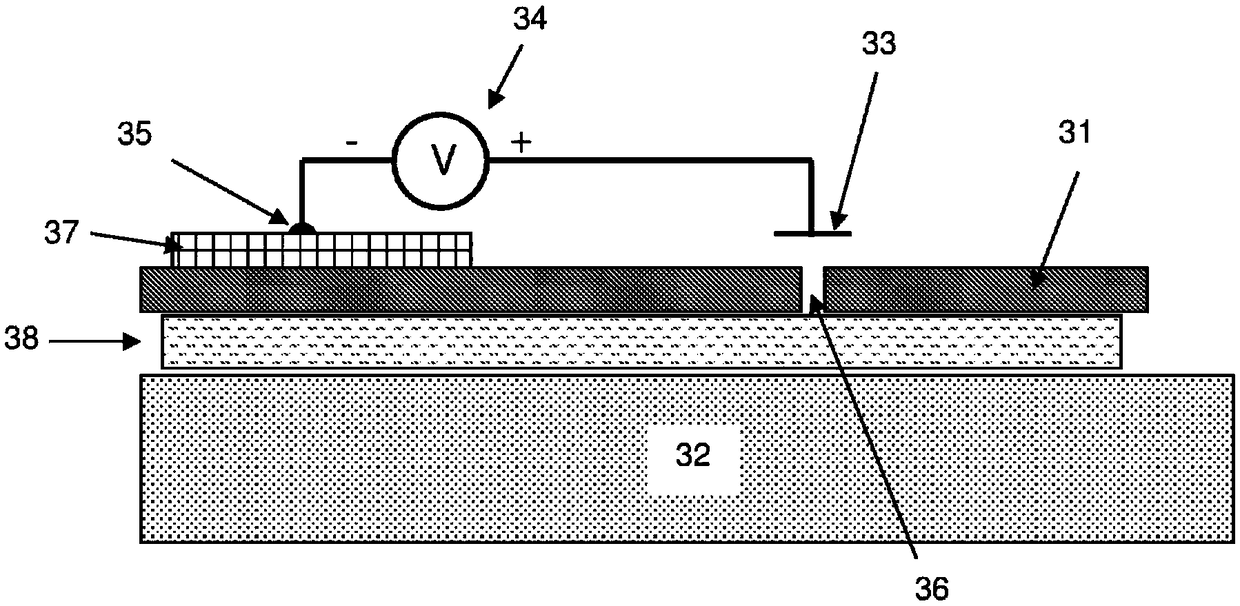

[0063]Example 1 - GCL rectangles of approximately 100 cm2 were made by needling a conductive geotextile through powdered bentonite clay into a backing of a woven non-conductive geomesh. The perforated geotextile fibers are sealed to the backing geomesh by flame melting the protruding fibers. Conductive geotextiles were prepared by coating a nonwoven low weight (150 g / m2) PET geotextile with a solution containing a graphene dispersion to achieve a 2% weight percent loading of graphene on the geotextile. The electrical resistance of the conductive geotextile was measured to be 2000 ohm / square and kept in the assembled GCL.

example 2

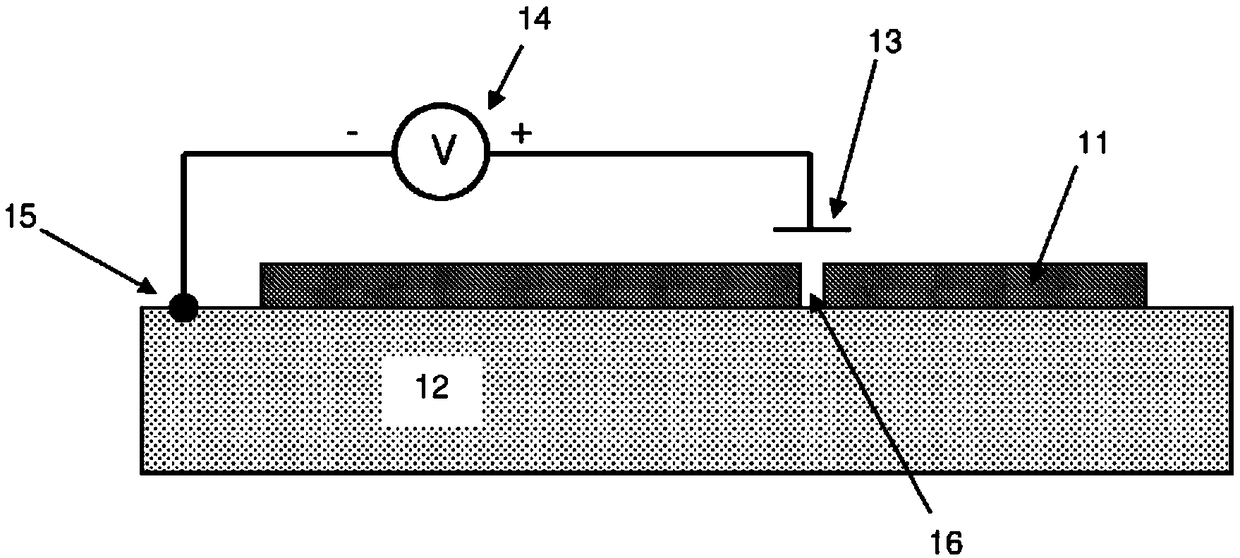

[0064] Example 2 - The sample from Example 1 was placed beneath a waterproof geomembrane with purposely formed holes punched therein. The diameter of the hole is about 1 mm. When tested with a spark detector at approximately 15,000 volts, the GCL samples from Example 1 proved to be suitable electrical conductors to allow spark testing of waterproof geomembranes and holes were reliably detected.

example 3

[0065] Example 3 - The resulting 100 cm2 commercial GCL was used and a conductive geotextile was adhered to an existing nonwoven, non-conductive geotextile surface by needling through the existing GCL. The conductive geotextile was the same material used in Example 1. The samples were tested according to Example 2 and the same results as in Example 2 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com