Standstone aggregate production system

A production system and aggregate technology, applied in the field of mining, can solve the problems of laborious and laborious, low efficiency of construction activities, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

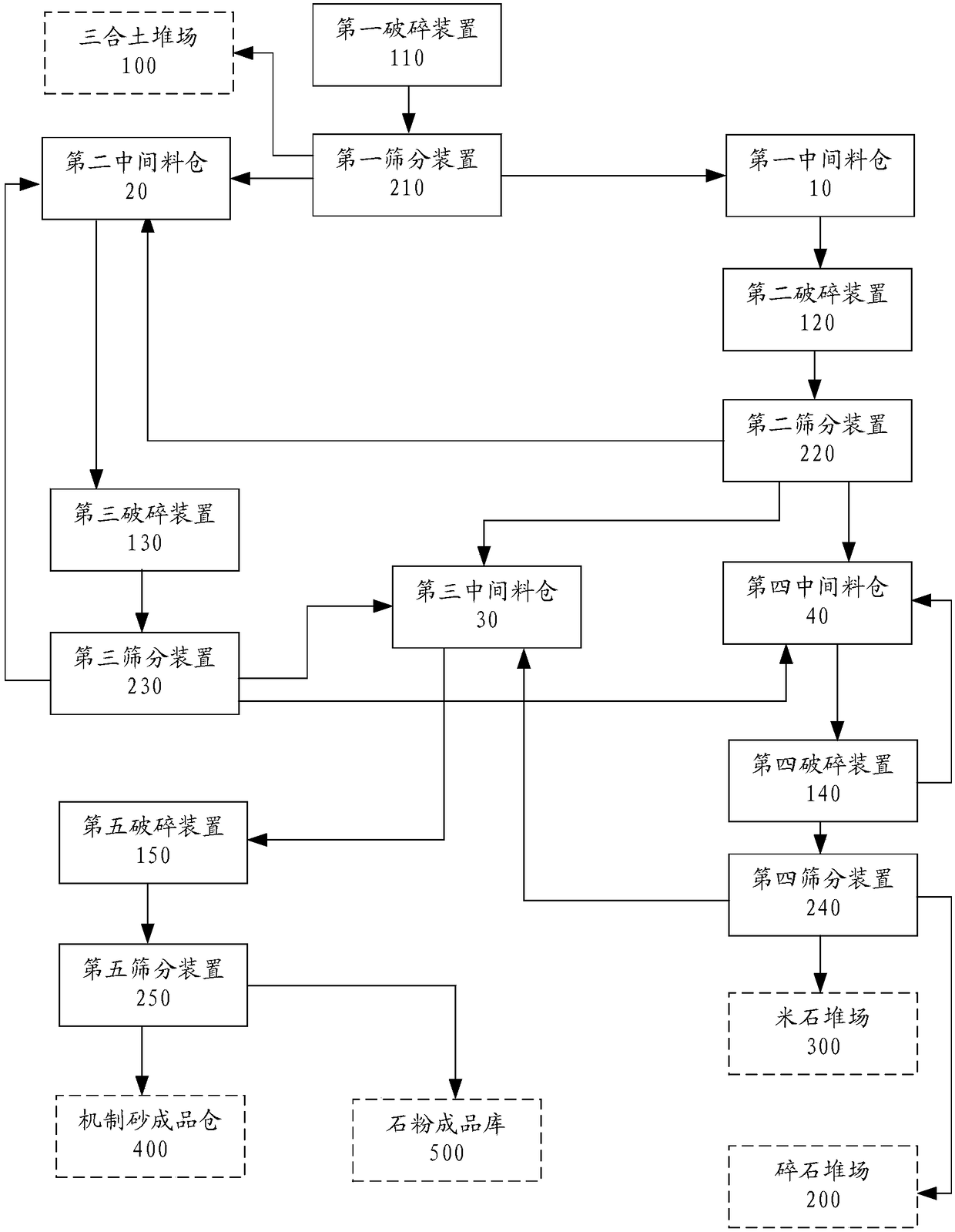

[0036] figure 1 It is a structural schematic diagram of an embodiment of a sand and gravel aggregate production system provided by the present invention.

[0037] refer to figure 1 As shown, the sand and gravel aggregate production system provided in this embodiment is used to produce sand and gravel aggregates required for construction by using ores collected from mountains. , finished sand, etc.

[0038] The system includes a first intermediate silo 10, a second intermediate silo 20, a third intermediate silo 30, a fourth intermediate silo 40, a first crushing device 110, a second crushing device 120, a third crushing device 130, a The fourth crushing device 140 , the fifth crushing device 150 , the first screening device 210 , the second screening device 220 , the third screening device 230 , the fourth screening device 240 and the fifth screening device 250 .

[0039] The above-mentioned silo, crushing device, and screening device are connected by a mineral material con...

Embodiment 2

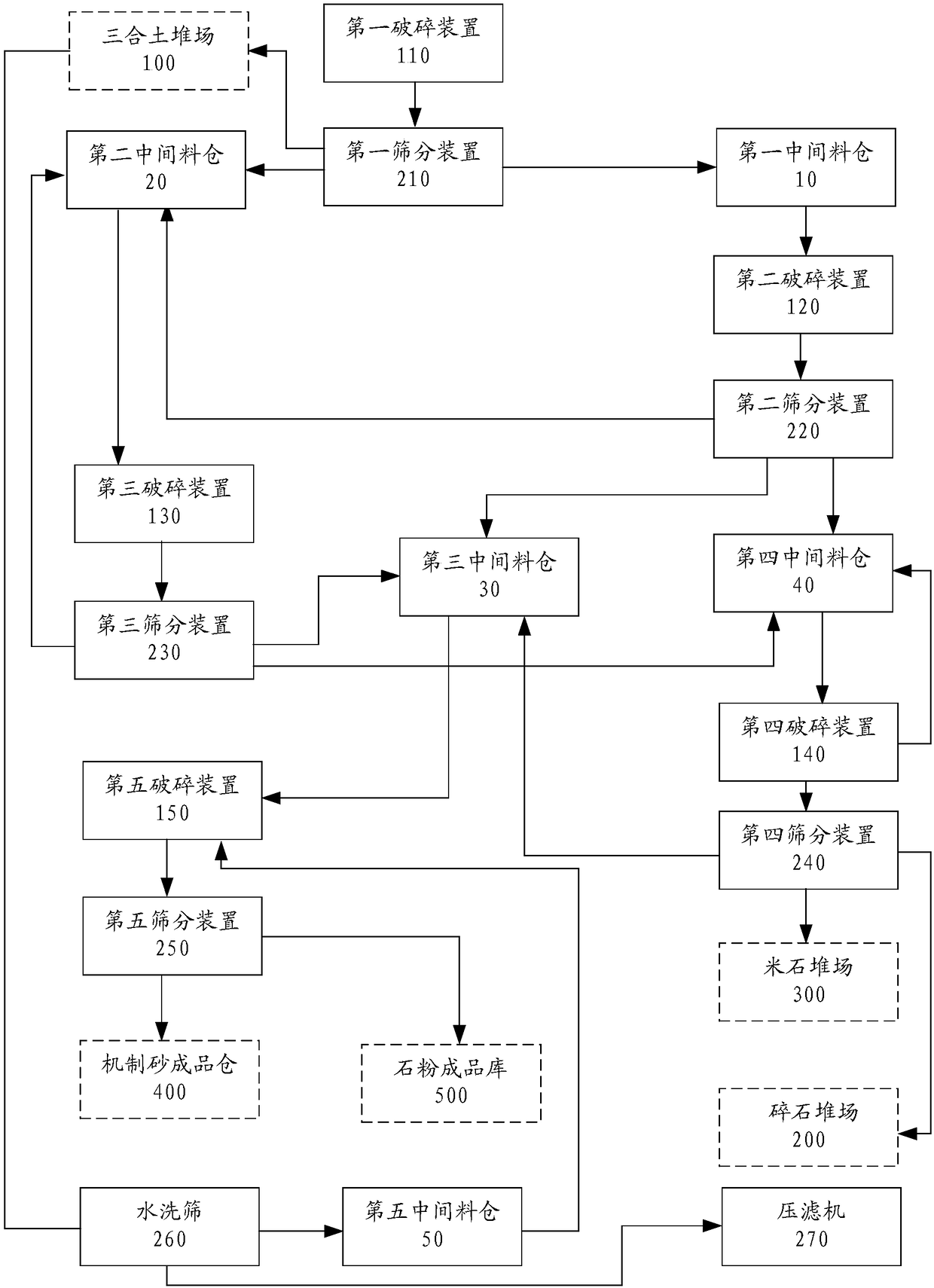

[0054] figure 2 It is a schematic structural diagram of another embodiment of a sand and gravel aggregate production system provided by the present invention.

[0055] refer to figure 2 As shown, the sand and gravel aggregate production system provided in this embodiment is based on the previous embodiment with additional washing screens 260 and a fifth intermediate storage bin 50 .

[0056] The washing sieve is used to further wash and screen the finished concrete with water, so as to separate the mineral materials of different sizes for further utilization. Mineral material and mud with a size larger than 1mm can be obtained through the sieving treatment of the washing screen, and the mud contains mineral material smaller than 1mm, but it has no use value.

[0057] After screening, the mineral materials with a size greater than 1mm are transported to the fifth intermediate silo, and the mineral materials in the fifth intermediate silo are then entered into the sand makin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com