De-moulded paraffin treatment system of cavity mould for precision pressure casting

A precision die-casting and processing system technology, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of single mold size requirements, no residual paraffin washing, and incomplete paraffin cleaning, etc., to achieve the effect of increasing applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific drawings. It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict.

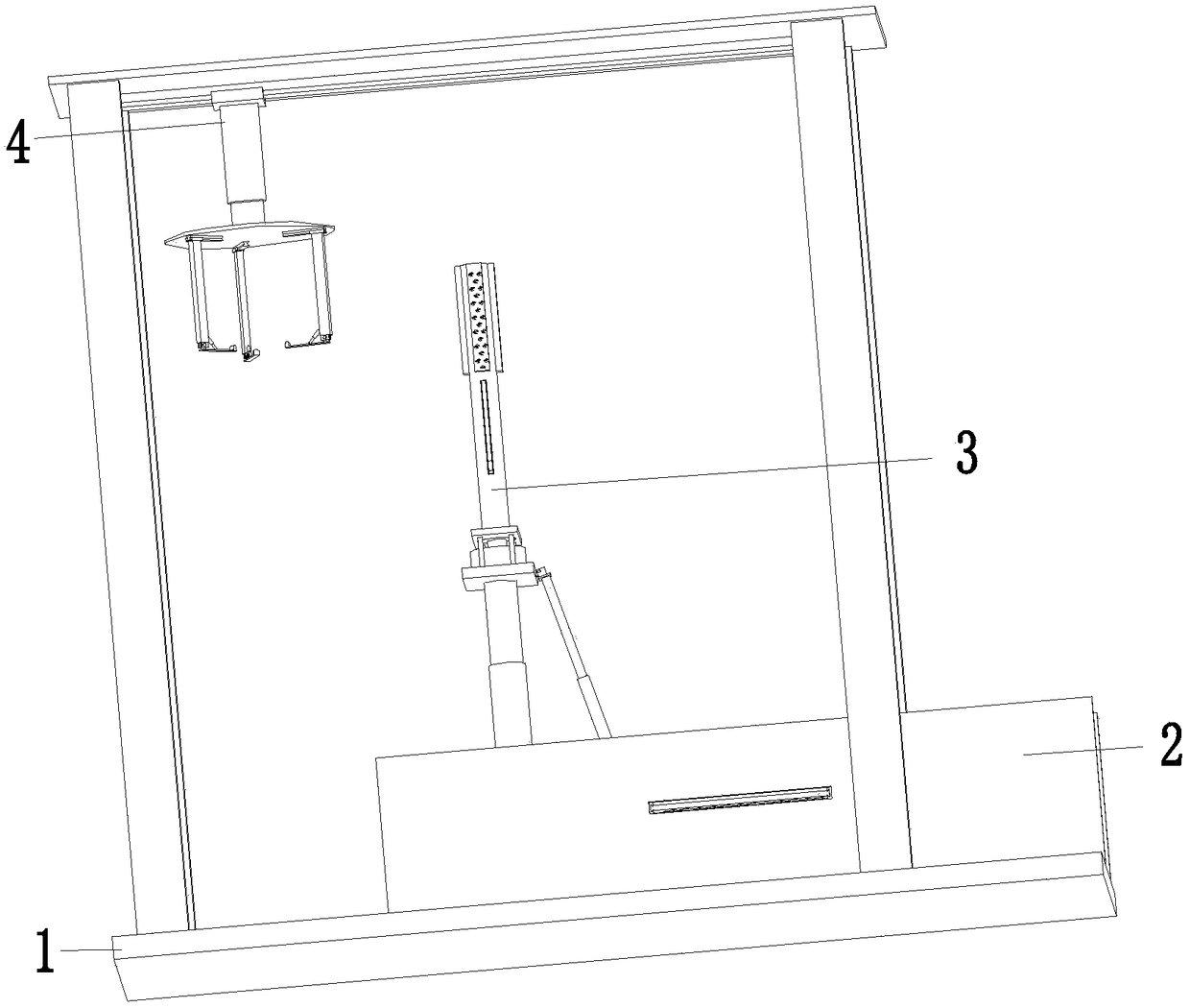

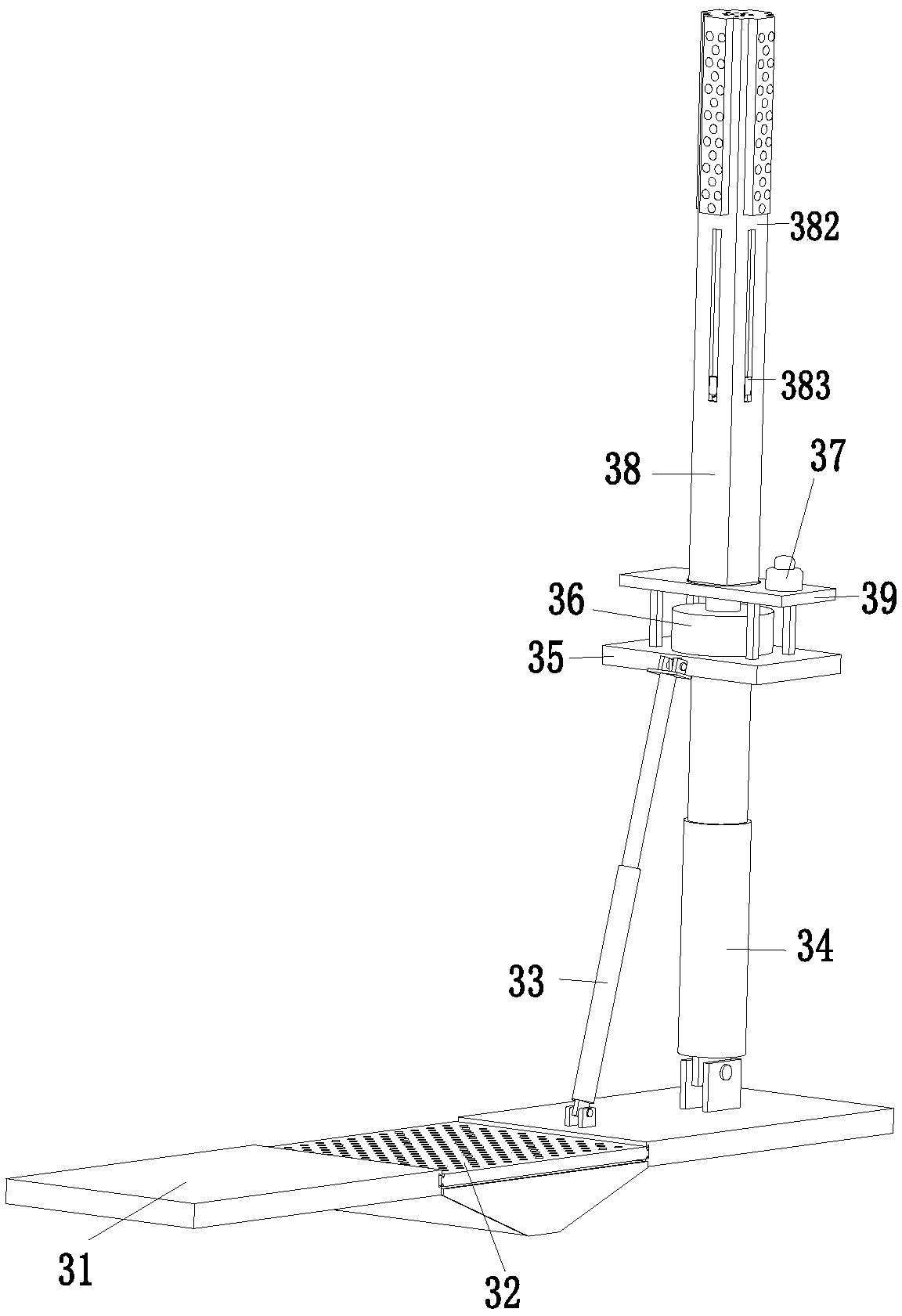

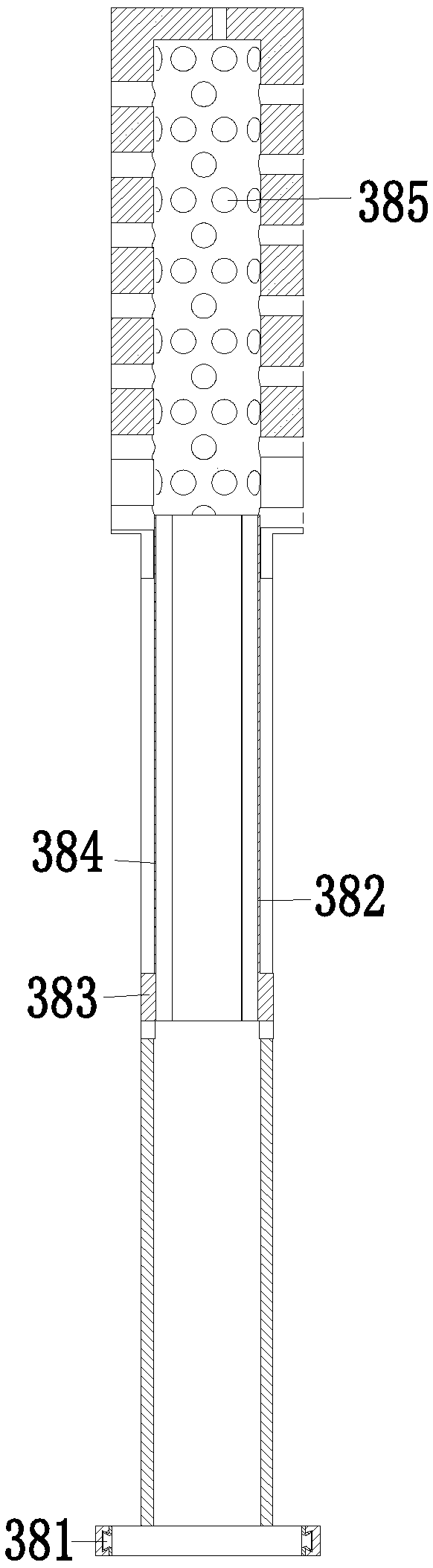

[0020] Such as Figure 1 to Figure 4 As shown, a paraffin treatment system for precision die-casting cavity molds after demolding includes a bottom plate 1, a supporting side plate 2, a cleaning device 3, and a conveying device 4. The number of the supporting side plates 2 is two, and the supporting side plate 2 It is installed symmetrically on the upper end surface of the middle part of the bottom plate 1, the cleaning device 3 is installed on the inner surface between the two supporting side plates 2, and the conveying device 4 is installed on the upper end surface of the bottom plate 1.

[0021] The convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com