Tool for laser-assisted machining of inner holes and method for adjusting laser incident angle

A laser-assisted, inner hole technology, applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of increasing tool wear, failing to achieve the quality of the machined surface, unable to solve the inner hole processing, etc., to solve the problem of the tool bar The temperature rise is too high, and the effect of freeing the incident point is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

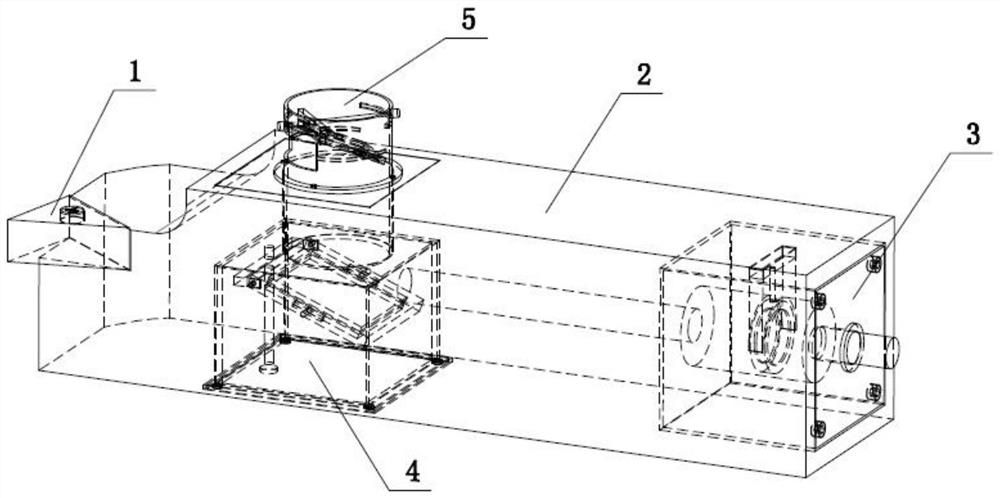

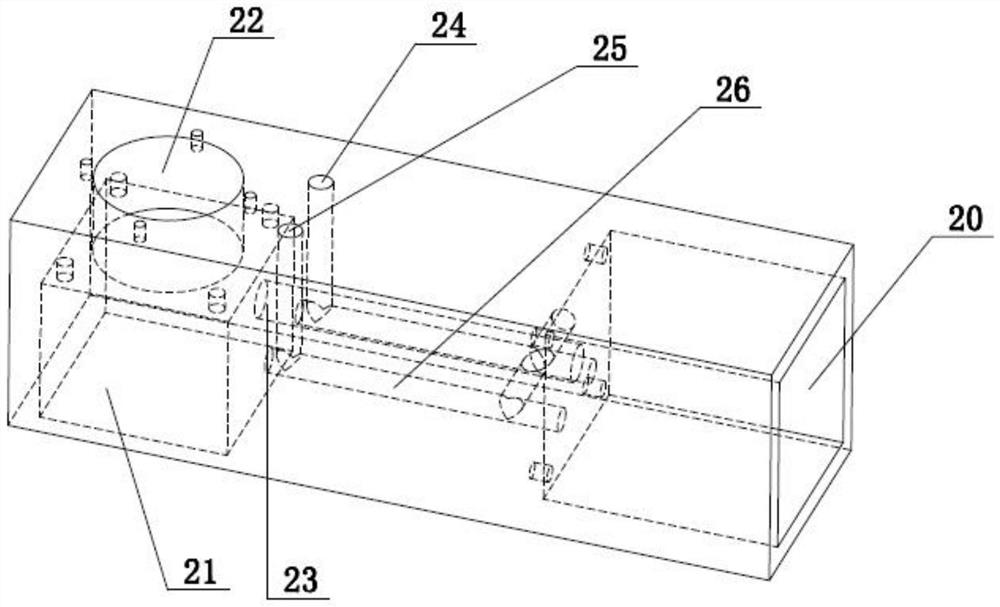

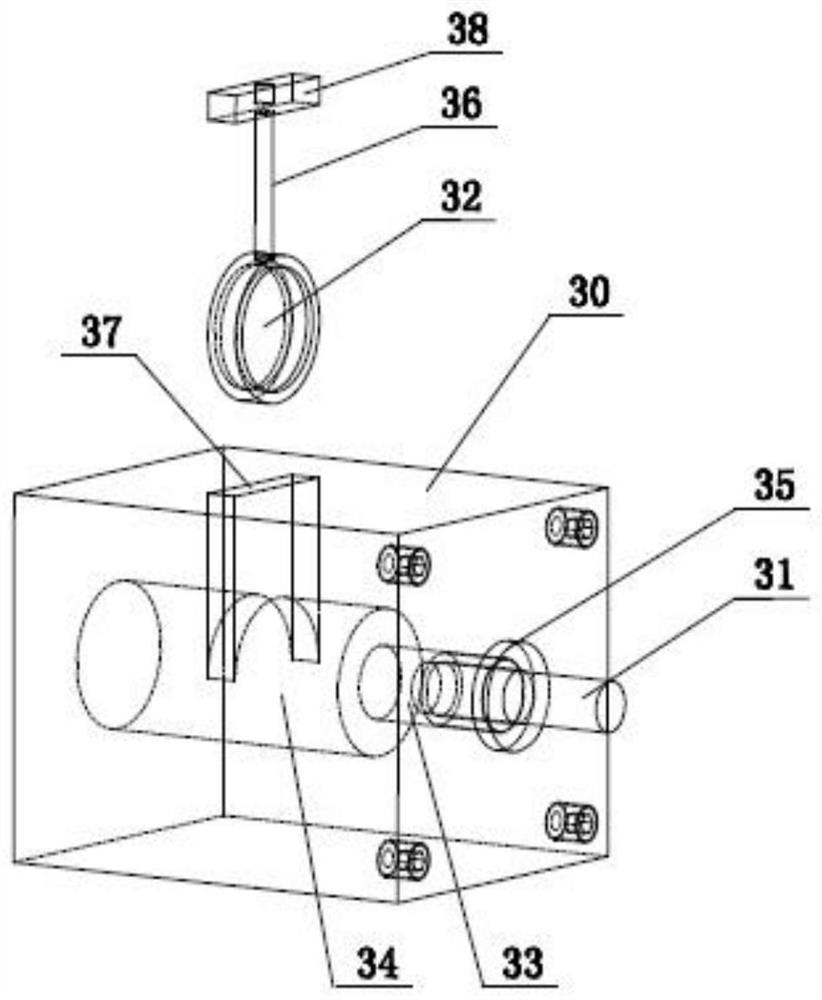

[0040] This embodiment provides a tool for laser-assisted machining of inner holes, such as figure 1 , figure 2 As shown, it includes a cutter head 1, a cutter bar 2, a first module 3, a second module 4 and a third module 5, the cutter head 1 is arranged at the head end of the cutter bar 2, and the tail end of the cutter bar 2 is provided with a first installation groove 20 The first end of the knife bar 2 is provided with a second mounting groove 21 and a third mounting groove 22 communicating with each other, and a first through hole 23 is also provided between the first mounting groove 20 and the second mounting groove 21 to make the two communicate with each other; One module 3 is arranged in the first installation groove 20, the second module 4 is arranged in the second installation groove 21, the third module 5 is arranged in the third installation groove 22; the first module 3 is provided with a convex lens 32, the second The module 4 is provided with a first concave ...

Embodiment 2

[0050] On the basis of the laser-assisted inner hole machining tool provided in Embodiment 1, this embodiment provides a method for adjusting the incident angle of the laser, including the following steps:

[0051] Step 1. Introduce the laser: the laser fiber 31 passes through the first inner hole 33 and the second inner hole 34 of the first block 30, and the laser passes through the convex lens 32 and then enters the interior of the cutter bar 2, and then enters the second through the first through hole 23. On the glass of the first concave lens 42 in the module 4;

[0052] Step 2, adjust the reflection angle: manually adjust the knob on the first adjustment rod 44 at the bottom of the block bottom plate 41 of the second block 40, so that the mirror of the first concave lens 42 in the second module 4 rotates around the fixed pin 46 , to adjust the reflection angle of the laser.

[0053] Step 3. Adjusting the incident angle: by manually adjusting the knob on the second adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com