A device and method for evaluating photoelectron emission performance of photocathode materials

A technology of emission performance and photocathode, which is applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve problems such as the limitation of angle change and the inability to meet parameter measurement, so as to avoid influence and compress lateral space Distribution range, easy-to-read effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

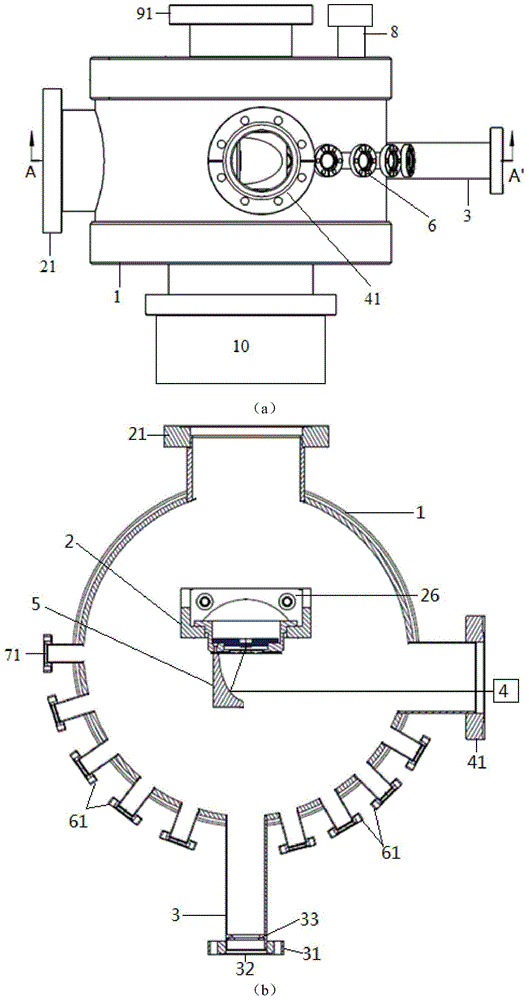

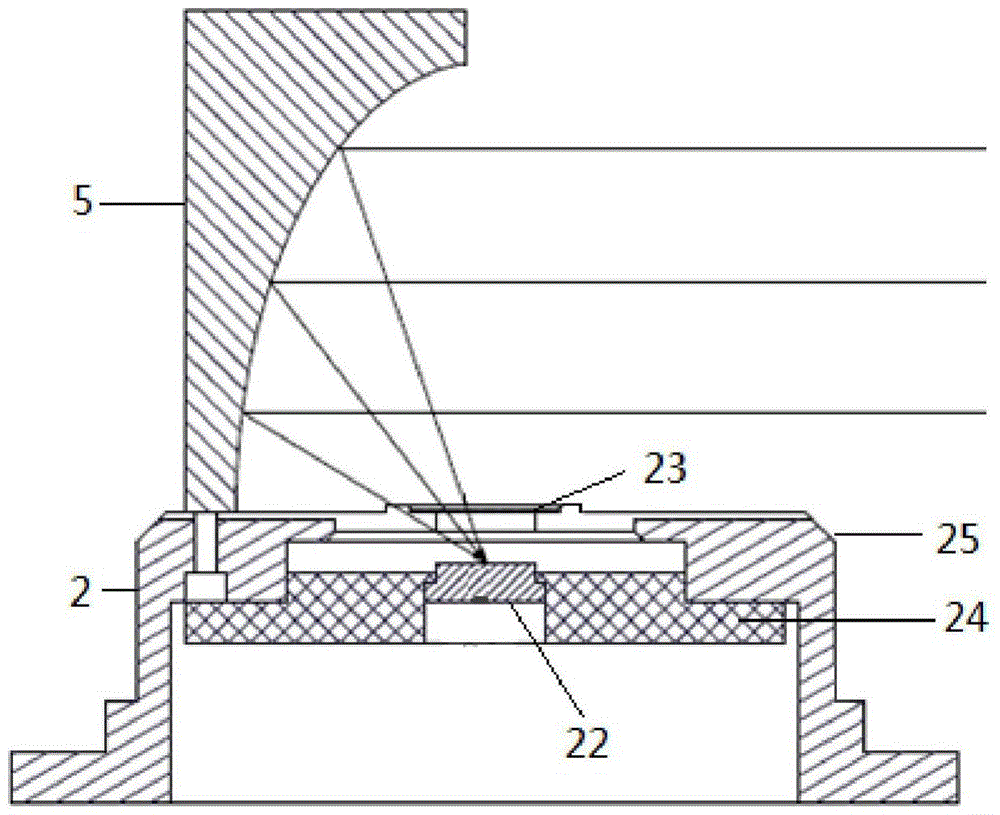

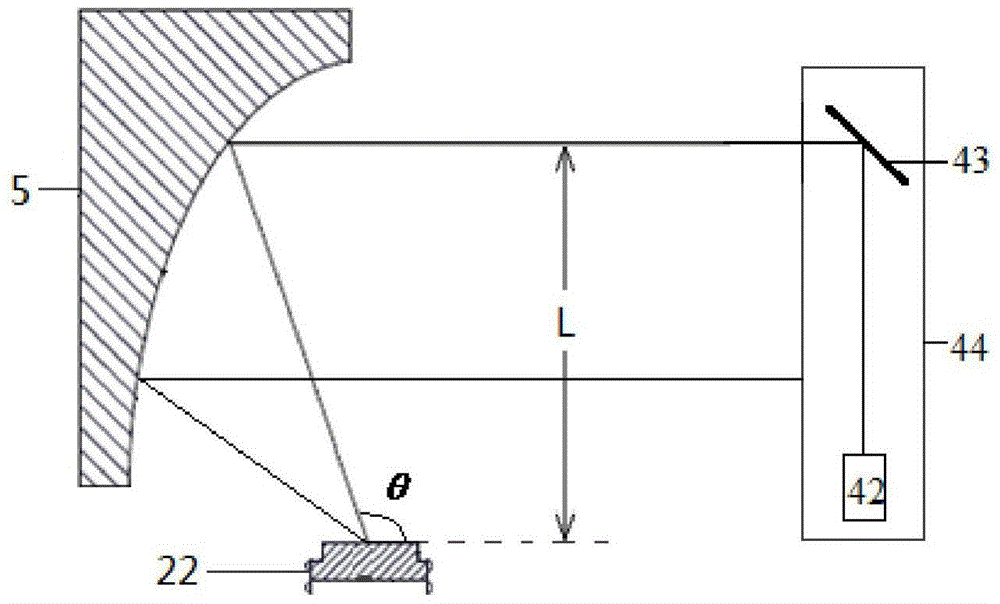

[0037] Such as figure 1 As shown, the photocathode material photoelectron emission performance evaluation device of this embodiment includes: a vacuum chamber 1, a vacuum pumping system 10, a vacuum degree measurement system, a photocathode assembly 2, a power supply system, an optoelectronic imaging system 3, and a data acquisition system 8 , the laser excitation system 4 and the focusing mirror 5, the focusing mirror 5 adopts a rotating parabolic mirror; wherein, the surface of the vacuum chamber 1 is connected to the vacuum pumping system 10 and the vacuum degree measuring system through the flange port respectively; in the vacuum chamber The surface of 1 is respectively provided with a mechanical installation flange port 21 and a power supply connection flange port 71. The photocathode assembly 2 enters the vacuum chamber 1 through the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com