Laminator for graphic design

A technology of graphic design and plastic sealing machine, which is applied in the field of machinery, can solve problems such as troublesome operation, uneven packaging quality, and many packaging steps, and achieve the effects of convenient operation, improved packaging effect, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

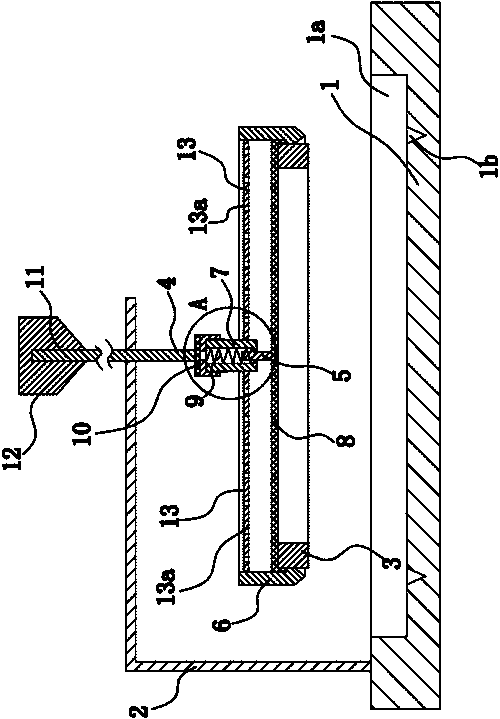

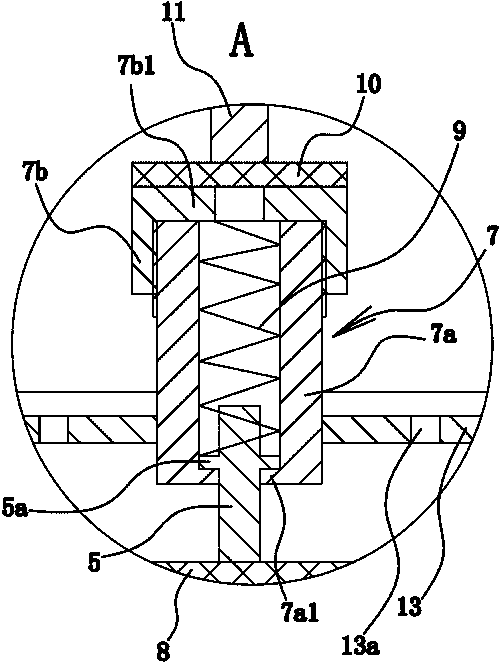

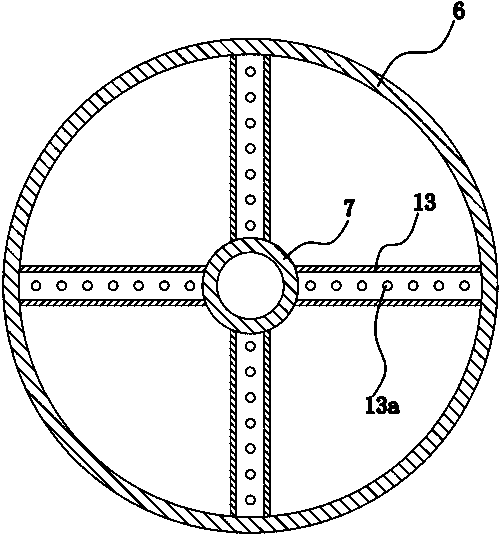

[0032] Such as Figure 1 to Figure 3 Shown, this planar design is made up of base plate 1, support 2, electric heating ring 3, driver 4, connecting rod 5, cutter 6 etc. with plastic sealing machine. Wherein, the cutter 6 is made of heat-conducting material, and the heat-conducting material can be brass, stainless steel and the like. In this embodiment, preferably the cutter 6 is made of stainless steel. The electric heating ring 3 is an existing product, which can be purchased on the market.

[0033] Specifically, the bottom plate 1 is flat, and in actual use, the bottom plate 1 is arranged along a horizontal direction. A placement slot 1a is provided in the middle of the upper side of the bottom plate 1, and the placement slot 1a is preferably square. A relief groove 1b is provided on the bottom wall of the placement groove 1a, the relief groove 1b is square, and the central axes of the relief groove 1b and the placement groove 1a are collinear.

[0034] The bracket 2 is ...

Embodiment 2

[0042] The structure and principle of the second embodiment are basically the same as that of the first embodiment, except that the driving part 4 is an electric push rod 11, and the electric push rod 11 is fixed on the bracket 2 through the frame, and the rod of the electric push rod 11 The part is fixed with the annular retaining edge 7b1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com