High-end plastic thin film conveying device

A plastic film and conveying device technology, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of no direct connection of the film conveyor, tearing or wrinkling of the film, increasing labor intensity of personnel, etc., and achieves a simple structure , reduce manpower and material resources, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

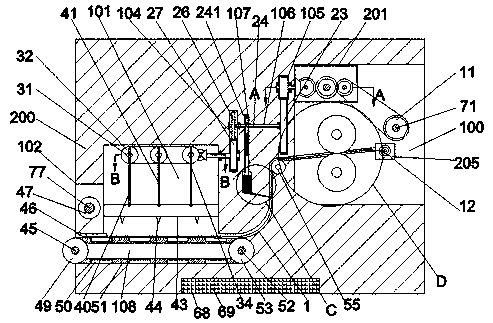

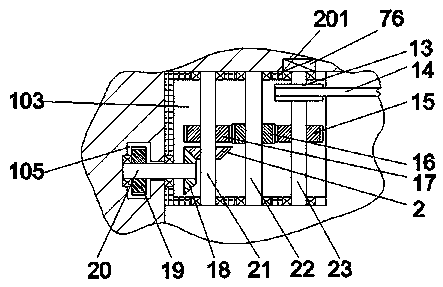

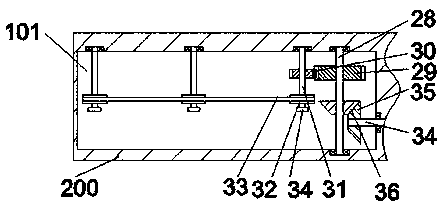

[0023] like Figure 1-5As shown, a high-end plastic film conveying device of the present invention includes an outer frame 200 and a conveying device located in the first cavity 100 with the opening on the right side of the outer frame 200 facing right and a conveying device located in the outer frame 200. 200 is the cutting device in the sliding cavity 101 on the left side, the top wall of the first cavity 100 is fixed with a gear housing 201, and the gear housing 201 has an installation cavity 103, and the front and rear end walls of the first cavity 100 can be Rotation is provided with a first rotating shaft 71, a mounting plate 73 and a first pulley 11 behind the mounting plate 73 are fixed on the first rotating shaft 71, and a front and rear pulley is connected to the far right side of the mounting cavity 103. The extended second rotating shaft 23, the front extension end of the second rotating shaft 23 is connected to the front end wall of the installation cavity 103 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com