Polyurethane polyol and preparation method and application thereof

A polyurethane polyol, reaction technology, applied in the field of polyurethane polyol and its preparation, can solve the problems of non-continuous production, low product quality, long reaction time, etc., achieve short reaction time, good dimensional stability, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

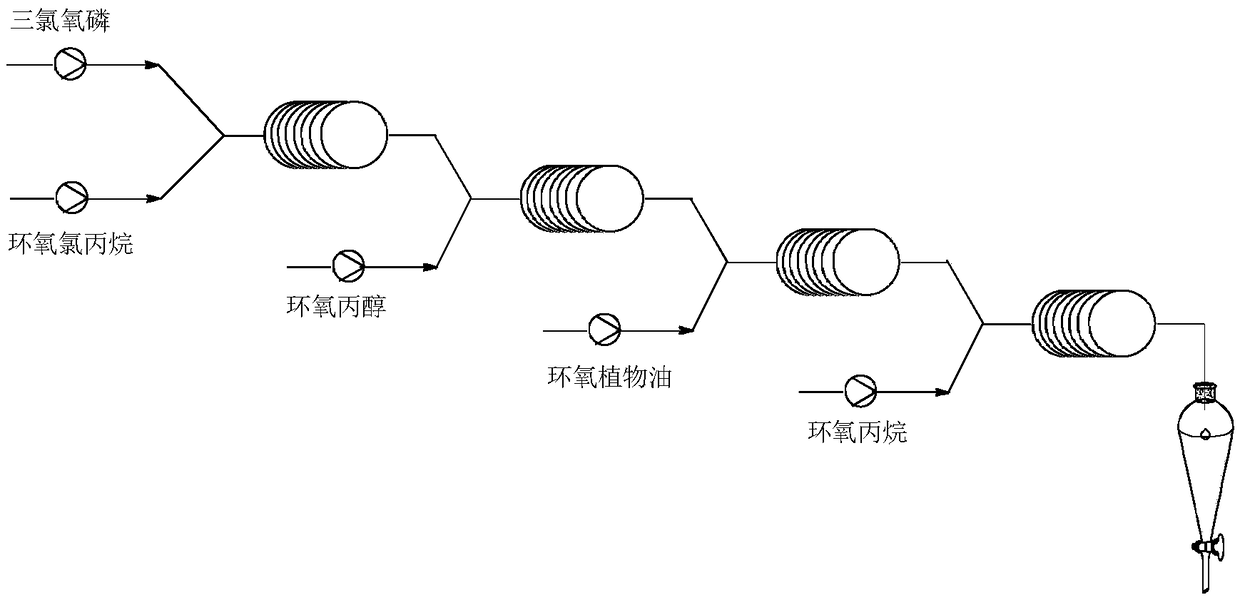

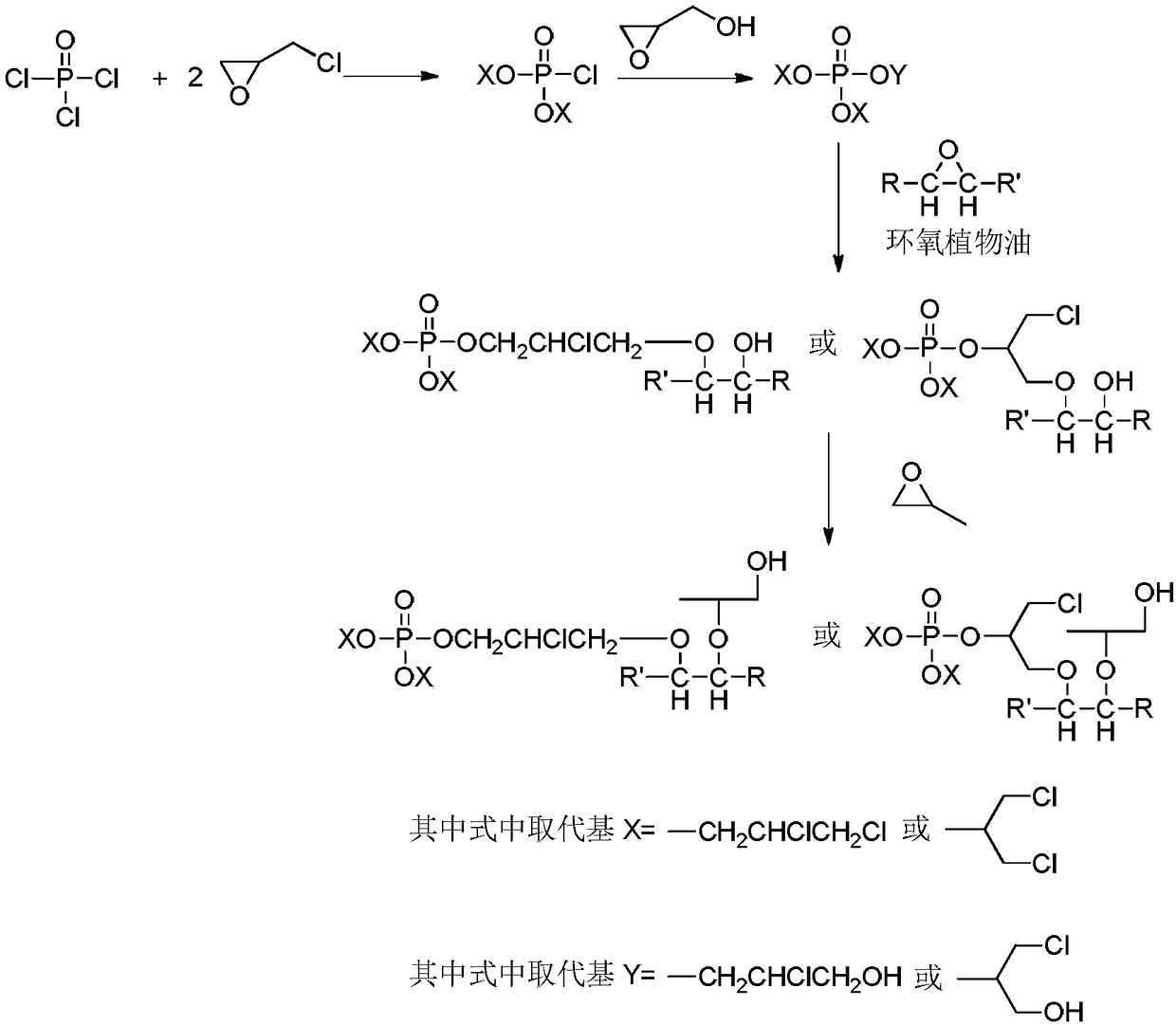

Method used

Image

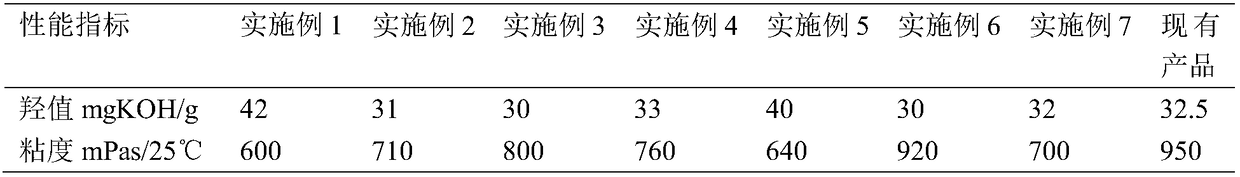

Examples

Embodiment 1

[0043] Take 153g of phosphorus oxychloride dissolved in 400ml of carbon tetrachloride to obtain solution A, take 195g of epichlorohydrin and 6.6g of aluminum chloride and dissolve in 400ml of carbon tetrachloride to obtain mixed solution B, take 74.08g of glycidyl alcohol and 4g of chlorine Aluminum chloride was dissolved in 800ml carbon tetrachloride to obtain mixed solution C, 216g epoxidized soybean oil and 0.06g cesium carbonate were dissolved in 1600ml carbon tetrachloride to obtain mixed solution D, 175g propylene oxide was dissolved in 3200ml carbon tetrachloride to obtain solution e. Wherein the molar ratio of phosphorus oxychloride, epichlorohydrin and glycidol is 1: 2.1: 1, the molar ratio of epoxy group and hydroxyl compound in epoxy vegetable oil is 1: 1.1, epoxy group in epoxy soybean oil The molar ratio of the group to propylene oxide is 1:11; the solution A and the solution B are pumped into the first micro-mixer respectively, and after being fully mixed, they a...

Embodiment 2

[0045] Get 153g of phosphorus oxychloride dissolved in 400ml of carbon tetrachloride to get solution A, get 203.5g of epichlorohydrin and 6.6g of aluminum chloride and dissolve in 400ml of carbon tetrachloride to get mixed solution B, get 96g of glycidyl alcohol and 4g of chlorine Aluminum chloride was dissolved in 800ml carbon tetrachloride to obtain mixed solution C, 308g epoxidized soybean oil and 0.09g cesium carbonate were dissolved in 1600ml carbon tetrachloride to obtain mixed solution D, 145g propylene oxide was dissolved in 3200ml carbon tetrachloride to obtain a solution e. Wherein the molar ratio of phosphorus oxychloride, epichlorohydrin and glycidol is 1: 2.2: 1.3, the molar ratio of epoxy group and hydroxyl compound in epoxy vegetable oil is 1: 1.3, epoxy group in epoxy soybean oil The molar ratio of group and propylene oxide is 1: 10; The volume of four series microchannel reactors of microchannel reaction device, the flow rate of solution A, B, C, D and E, the ...

Embodiment 3

[0047] The difference from Example 1 is that the reaction temperatures of the four microchannel reactors are 80°C, 90°C, 110°C, and 115°C in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com