A kind of nanometer copper and preparation method thereof

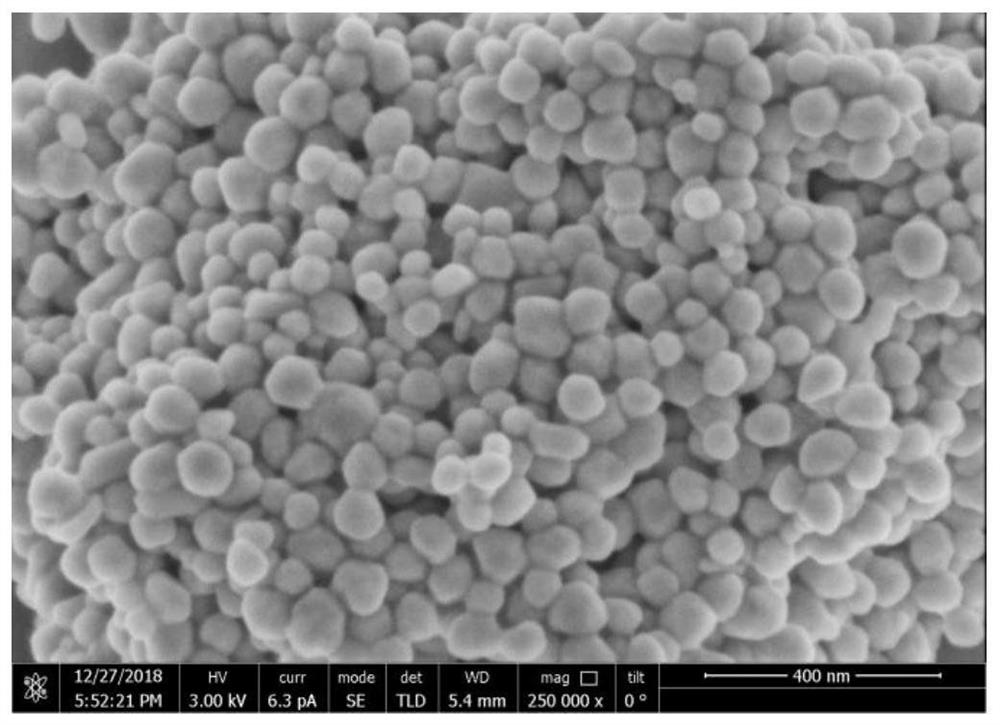

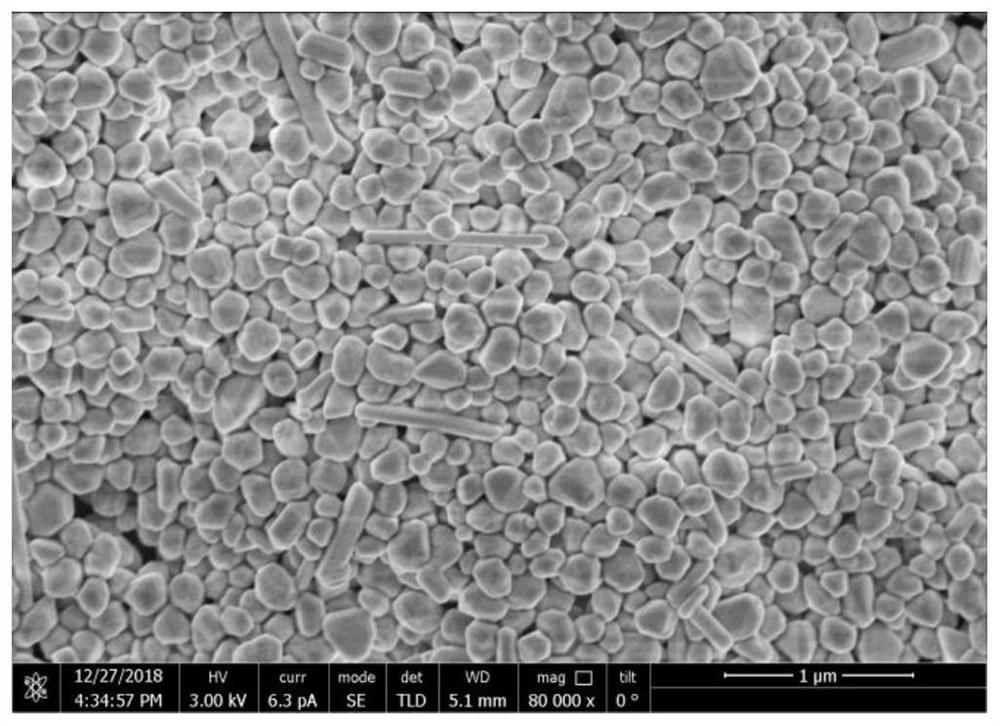

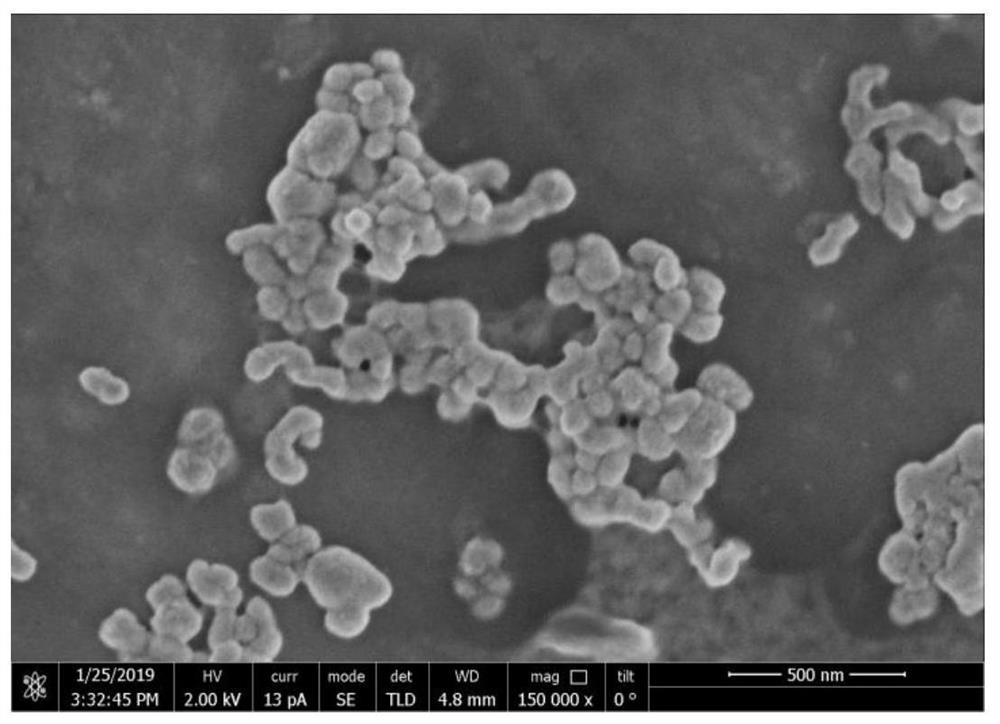

A technology of nano-copper and copper chloride dihydrate, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy agglomeration of nano-copper particles, high production cost, long reaction time, etc. , to achieve the effect of favorable cleaning, less agglomeration and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) Configure five solutions or reagents

[0058] a. Mix glycerol and deionized water in a volume ratio of 3:2 to form a reaction solution A;

[0059] b. Dissolve copper chloride dihydrate in solution A to form CuCl 2 Concentration is the reaction solution B of 0.02mol / L;

[0060] c. polyvinylpyrrolidone is dissolved in solution A to form a reaction solution C whose PVP concentration is 0.06mol / L;

[0061] d. Ascorbic acid is dissolved in solution A to form a reaction solution D whose concentration of ascorbic acid is 0.04mol / L;

[0062] e. Sodium hydroxide is dissolved in deionized water to form a sodium hydroxide reaction solution E with a concentration of 1mol / L;

[0063] (2) Take 30 mL of reaction solution C, add it dropwise to 30 mL of reaction solution D, and magnetically stir at 80° C. for 15 min to form mixed solution F. Take 20 mL of reaction solution B, add it dropwise to mixed solution F, and magnetically stir at 80°C for 15 min to form mixed solution G. ...

Embodiment 2

[0066] (1) Configure five solutions or reagents

[0067] a. Mix glycerol and deionized water in a volume ratio of 3:2 to form a reaction solution A;

[0068] b. Dissolve copper chloride dihydrate in solution A to form CuCl 2 Concentration is the reaction solution B of 0.02mol / L;

[0069] c. polyvinylpyrrolidone is dissolved in solution A to form a reaction solution C whose PVP concentration is 0.06mol / L;

[0070] d. Ascorbic acid is dissolved in solution A to form a reaction solution D whose concentration of ascorbic acid is 0.04mol / L;

[0071] e. Sodium hydroxide is dissolved in deionized water to form a sodium hydroxide reaction solution E with a concentration of 1mol / L;

[0072] (2) Take 30 mL of reaction solution C, add it dropwise to 30 mL of reaction solution D, and magnetically stir at 80° C. for 15 min to form mixed solution F. Take 20 mL of reaction solution B, add it dropwise to mixed solution F, and magnetically stir at 80°C for 15 min to form mixed solution G. ...

Embodiment 3

[0075] (1) Configure five solutions or reagents

[0076] a. Mix glycerol and deionized water in a volume ratio of 3:2 to form a reaction solution A;

[0077] b. Dissolve copper chloride dihydrate in solution A to form CuCl 2 Concentration is the reaction solution B of 0.02mol / L;

[0078] c. polyvinylpyrrolidone is dissolved in solution A to form a reaction solution C whose PVP concentration is 0.06mol / L;

[0079] d. Ascorbic acid is dissolved in solution A to form a reaction solution D whose concentration of ascorbic acid is 0.04mol / L;

[0080] e. Sodium hydroxide is dissolved in deionized water to form a sodium hydroxide reaction solution E with a concentration of 1mol / L;

[0081] (2) Take 30 mL of reaction solution C, add it dropwise to 30 mL of reaction solution D, and magnetically stir at 80° C. for 15 min to form mixed solution F. Take 20 mL of reaction solution B, add it dropwise to mixed solution F, and magnetically stir at 80°C for 15 min to form mixed solution G. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com