Preparation method of elastic handheld bag carrying device

A bag-carrying, hand-held technology is applied in the field of preparation of elastic hand-held bag-carrying devices, which can solve the problems of falling off iron filings, uncomfortable and convenient use, and poor elasticity of the bag-carrying device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

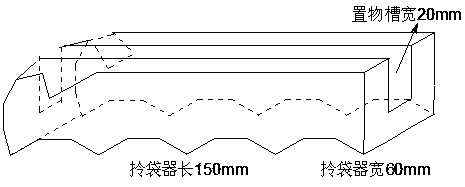

Image

Examples

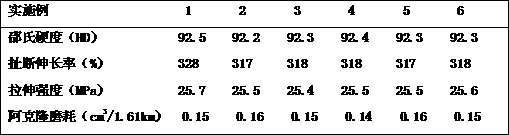

Embodiment 1

[0012] The styrene-butadiene rubber is baked and cut separately for use; put the cut raw rubber into an internal mixer at a temperature of 35 °C for 5 minutes to obtain plasticized rubber; add the obtained plasticized rubber at 45 °C Calcium bicarbonate, anti-aging agent, light absorbing agent, colorant, white carbon black and diatomaceous earth and other compounding agents are used to prepare the masterbatch; then the obtained masterbatch is prepared at a roll temperature of 45 °C and a roll distance of 3 mm Repeatedly refining 5 times on the open mill, adding the weighed sulfur and dicumyl peroxide and mixing, mixing for 10 minutes, the compounding agent is 55.5 parts in total; finally the obtained film is cut into 10 cm wide rubber strips and placed Put it into the feeding port of the injection molding machine, and vulcanize for 10 minutes under the conditions of 175 ℃ and 5MPa, so that the connection method of the compound rubber in the injection molding machine is extrusio...

Embodiment 2

[0013] Examples 2-5 The preparation method of Example 6 is the same as that of Example 1, and the process conditions are as follows:

Embodiment 2

[0015] In this embodiment, the masticating temperature is 40°C, and the kneading temperature is 50°C. Injection compression molding machine temperature 175 ℃, pressure 6MPa, vulcanization 10min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com