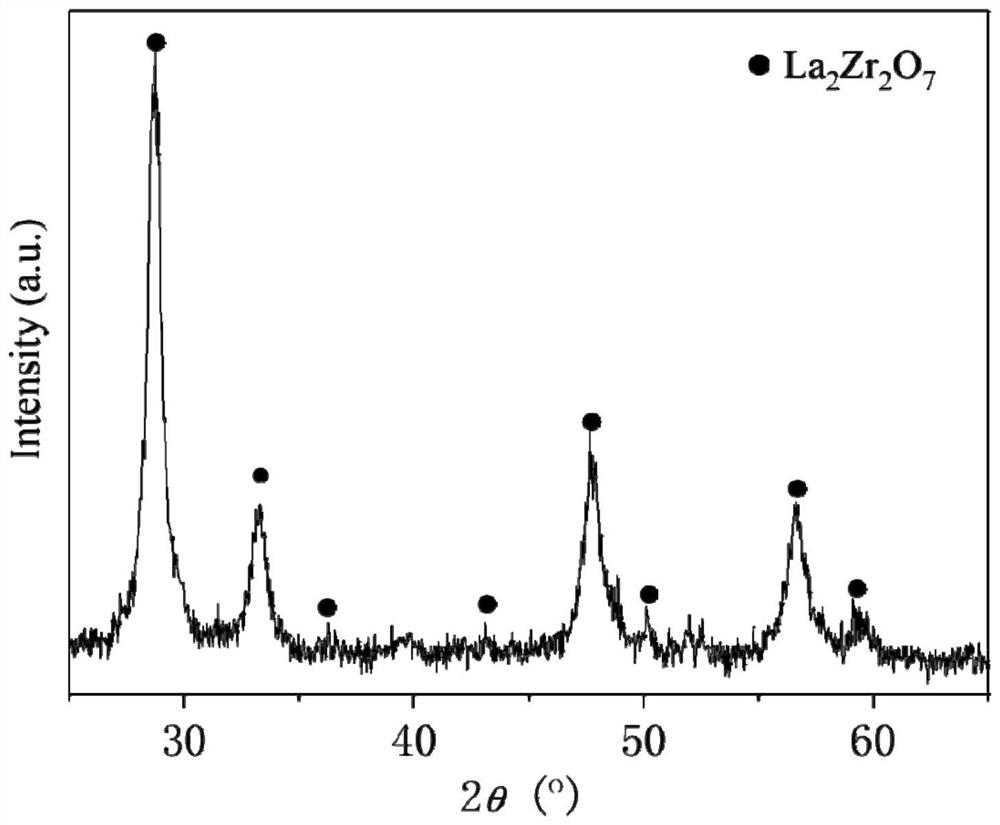

a la 2 zr 2 o 7 Up-conversion luminescent material and preparation method thereof

A technology of luminescent materials and solutions, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the performance of luminescent materials, bulk lattice defects, increasing particle surface, etc. Ask for simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: polymer network gel method prepares La 1.7 Zr 2 o 7 :Er 0.1 , Yb 0.2 Up-conversion luminescent material: La(NO 3 ) 3 ·6H 2 O, Er(NO 3 ) 3 ·6H 2 O, Yb(NO 3 ) 3 ·6H 2 O and ZrO(NO 3 ) 2 2H 2 O was used as the main raw material to prepare solutions containing La, Er, Yb and Zr at concentrations of 1.0 mol / L, 0.2 mol / L, 0.2 mol / L and 1.0 mol / L, respectively. Take La at a concentration of 1.0 mol / L 3+ Solution 42.50 mL, 0.2 mol / L Er 3+ Solution 12.50 mL, 0.2 mol / L Yb 3+ Solution 25.00 mL, 1.0 mol / L Zr 4+ Solution 50.00 mL and 100.00 mL H 2 0 to a 500 mL beaker and mix evenly to obtain a mixed ion solution; respectively weigh 12 g of acrylamide and 2 g of N,N-methylenebisacrylamide at a mass ratio of 6:1 and add them to the mixed ion solution, and magnetically Stir for 1 h; then place the solution at 80 o Stir in the water bath for 0.5 h in the C water bath, add 1.00 mL of the newly prepared ammonium persulfate solution with a mass fraction ...

Embodiment 2

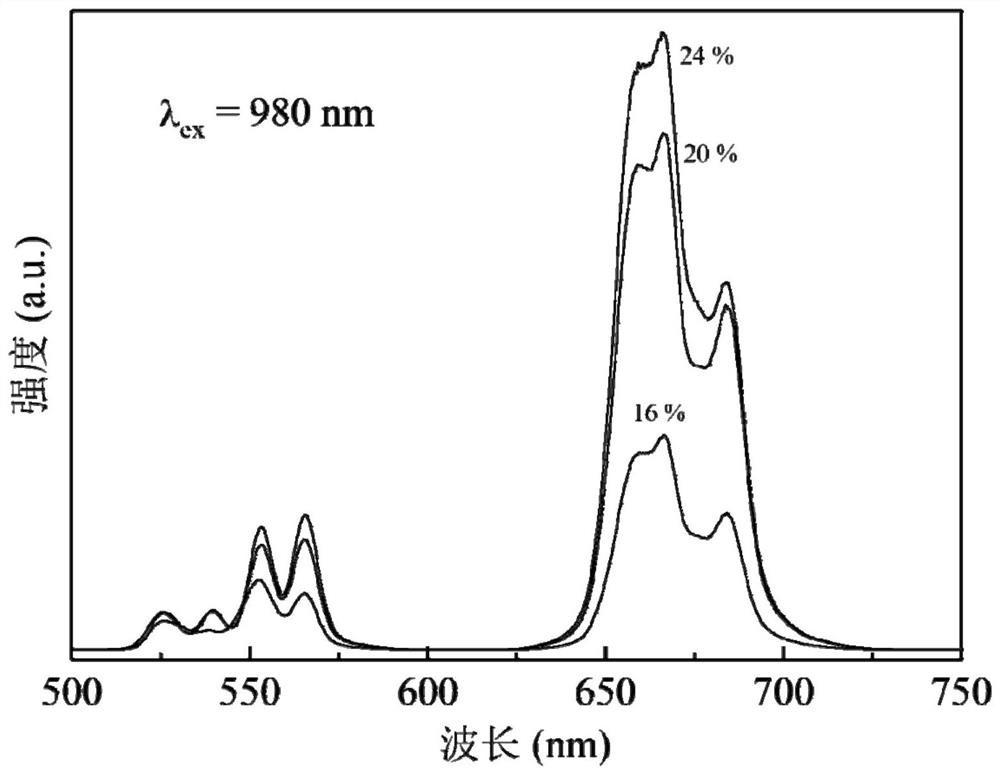

[0026] Embodiment 2: polymer network gel method prepares La 1.86-2y Zr 2 o 7 :Er 0.14 , Yb 2y ( y = 0.16, 0.20,0.24) series of up-conversion luminescent materials: LaCl 3 ·6H 2 O, ErCl 3 ·6H 2 O, YbCl 3 ·6H 2 O and ZrOCl 2 ·8H 2 O was used as the main raw material, and the solutions containing La, Er, Yb and Zr at concentrations of 0.5 mol / L, 0.1 mol / L, 0.2 mol / L and 1.0 mol / L were prepared, respectively. Take three parts of Er with a concentration of 0.1 mol / L 3+ Solution 28.00 ml and 1.0 mol / L Zr 4+ Solution 40.00 mL to 100 mL H 2 O in the 500 mL beaker A, beaker B and beaker C, according to Yb 3+ The doping amount was designed to be 16%, 20% and 24%, and 0.5 mol / L of La was added to beaker A, beaker B and beaker C respectively 3+ solution 61.6 mL, 58.4 mL and 55.2 mL, then add 0.2 mol / L Yb in beaker A, beaker B and beaker C respectively 3+ 32.00 mL, 40 mL, and 48 mL of the solution were stirred evenly to obtain a mixed ion solution; 10 g of acrylamide and...

Embodiment 3

[0027] Embodiment 3: polymer network gel method prepares La 1.7 Zr 2 o 7 :Er 0.1 , Yb 0.2 Up-conversion luminescent material: La 2 o 3 、Er 2 o 3 , Yb 2 o 3 and ZrOCl 2 ·8H 2 O is the main raw material. A certain amount of rare earth oxides is weighed and dissolved in concentrated nitric acid. The corresponding rare earth-containing solutions are obtained after heating and decomposing excess concentrated nitric acid. The concentrations of La, Er, Yb and Zr solutions are respectively prepared to be 1.0 mol / L, 0.2 mol / L, 0.2 mol / L, 1.0 mol / L solutions. Take La at a concentration of 1.0 mol / L 3+ Solution 42.50 mL, 0.2 mol / L Er 3+ Solution 12.50 mL, 0.2 mol / L Yb 3+ Solution 25.00 mL, 1.0 mol / L Zr 4+ Solution 50.00 mL and 100.00 mL H 2 0 to a 500 mL beaker and mix evenly to obtain a mixed ion solution; respectively weigh 12 g of acrylamide and 2 g of N,N-methylenebisacrylamide at a mass ratio of 6:1 and add them to the mixed ion solution, and magnetically Stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com