Electric hoisting embracing pole for building electric transmission line towers in groups

A technology for transmission line towers and poles, applied in towers, building types, buildings, etc., can solve problems such as personal safety of construction personnel, insufficient terrain space, and large construction risks that affect transmission line towers, so as to easily avoid obstacles and reduce Safety incidents, the effect of reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

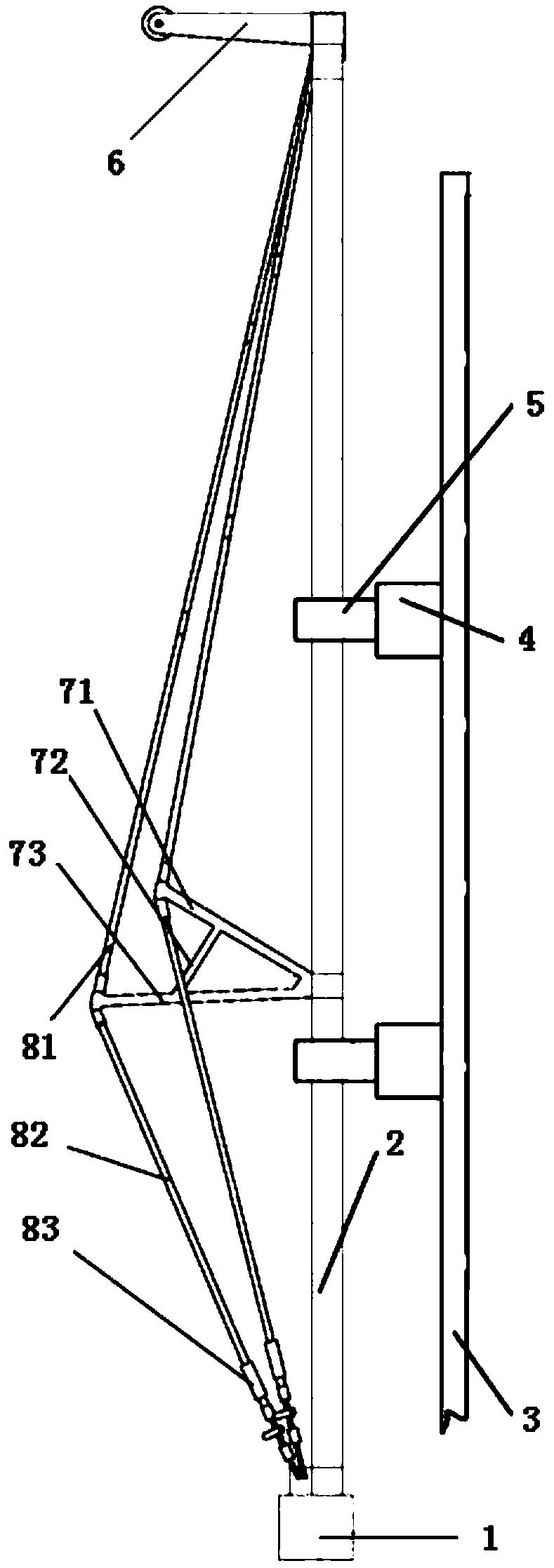

[0023] Such as figure 1 and figure 2 As shown, an electric lifting pole for erecting a transmission line tower includes a pole 2, the bottom of the pole 2 is fixedly provided with a lifting mechanism 1, and the lifting mechanism 1 is used for installing the pole 2, when lifting the pole 2, it also includes a guide mechanism 5, which is used to guide the pole 2 vertically upward when lifting the pole 2, and the guide mechanism 5 passes through the fastener 4 Fixedly arranged on the tower pole 3, the top of the holding pole 2 is provided with a lifting mechanism 6, and the lifting mechanism is used to lift the branch assembly of the transmission line tower when the transmission line tower is erected;

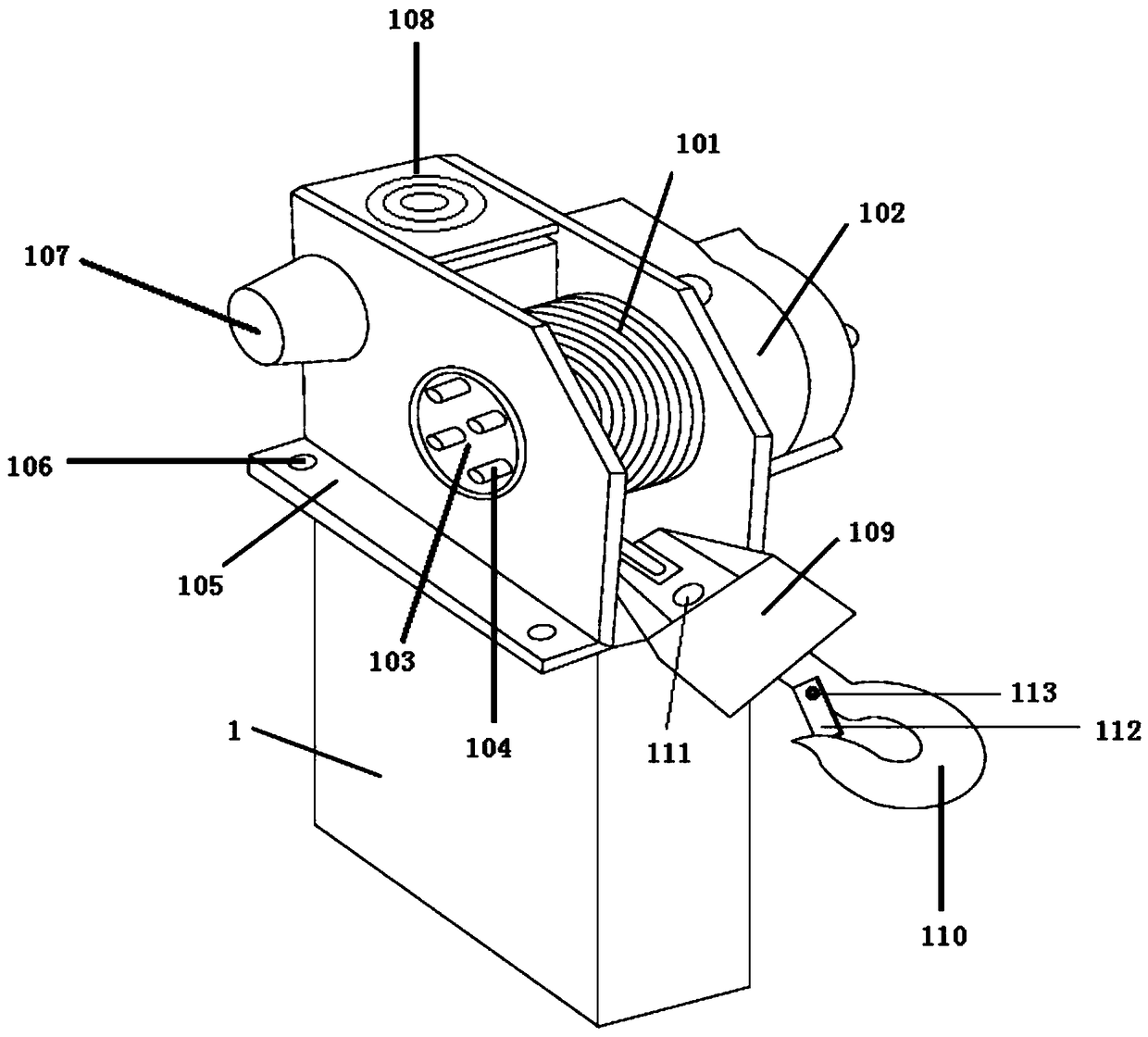

[0024]Wherein, the middle part of the lifting mechanism 1 is provided with a connecting plate 105, and a row of mounting holes 106 are opened on the connecting plate 105, and the connecting plate is installed on the pole through the mounting holes, and the lifting mechanism 1 ru...

Embodiment 2

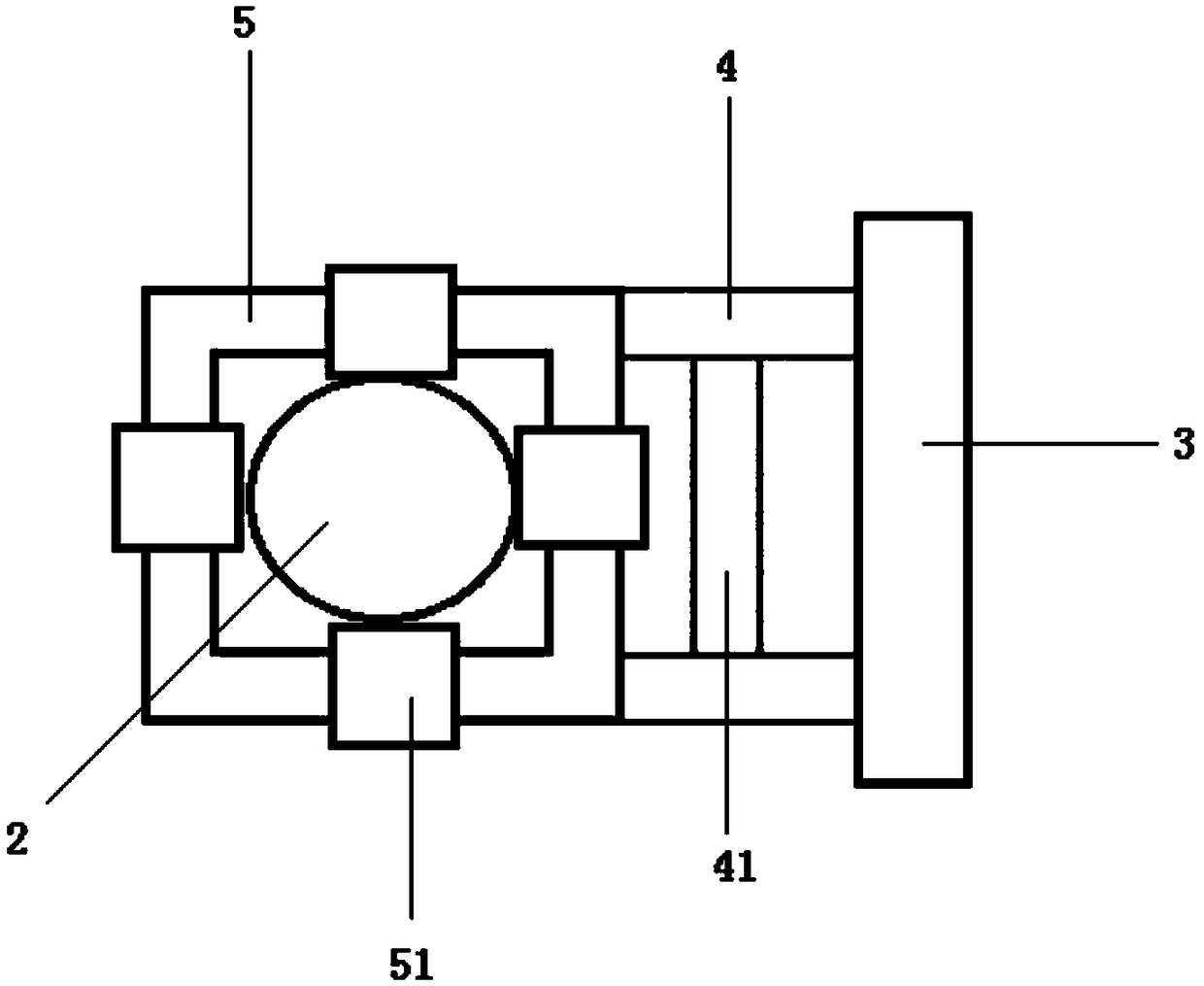

[0026] In the case of an electric lifting pole for erecting a power transmission line tower described in the above-mentioned embodiment 1, further as follows image 3 and Figure 4 As shown, the guide mechanism 5 is a rectangular frame, and the middle part of each frame of the rectangular frame is provided with a guide pulley 51, and the holding rod is the middle part of the rectangular frame, and the holding rod is in sliding contact with the guide pulley. However, there is no lateral pressure between the pole and the guide pulley. Usually, during the lifting of the pole, the construction system will be unstable due to lateral shaking. If the lateral shaking is too large, it is very likely There will be construction accidents. After the auxiliary function of the guide pulley, the lifting process of the holding pole is more stable, thereby ensuring construction safety.

[0027] Further, the fastening part 4 is welded with reinforcing ribs 41, the reinforcing ribs can strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com