Five-freedom-degree magnetic suspension flywheel

A magnetic levitation, degree of freedom technology, applied in the flywheel and other directions, can solve the problems of mode reduction, uncontrollable unbalanced vibration, affecting the service life of the flywheel, the attitude control accuracy and stability of the spacecraft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

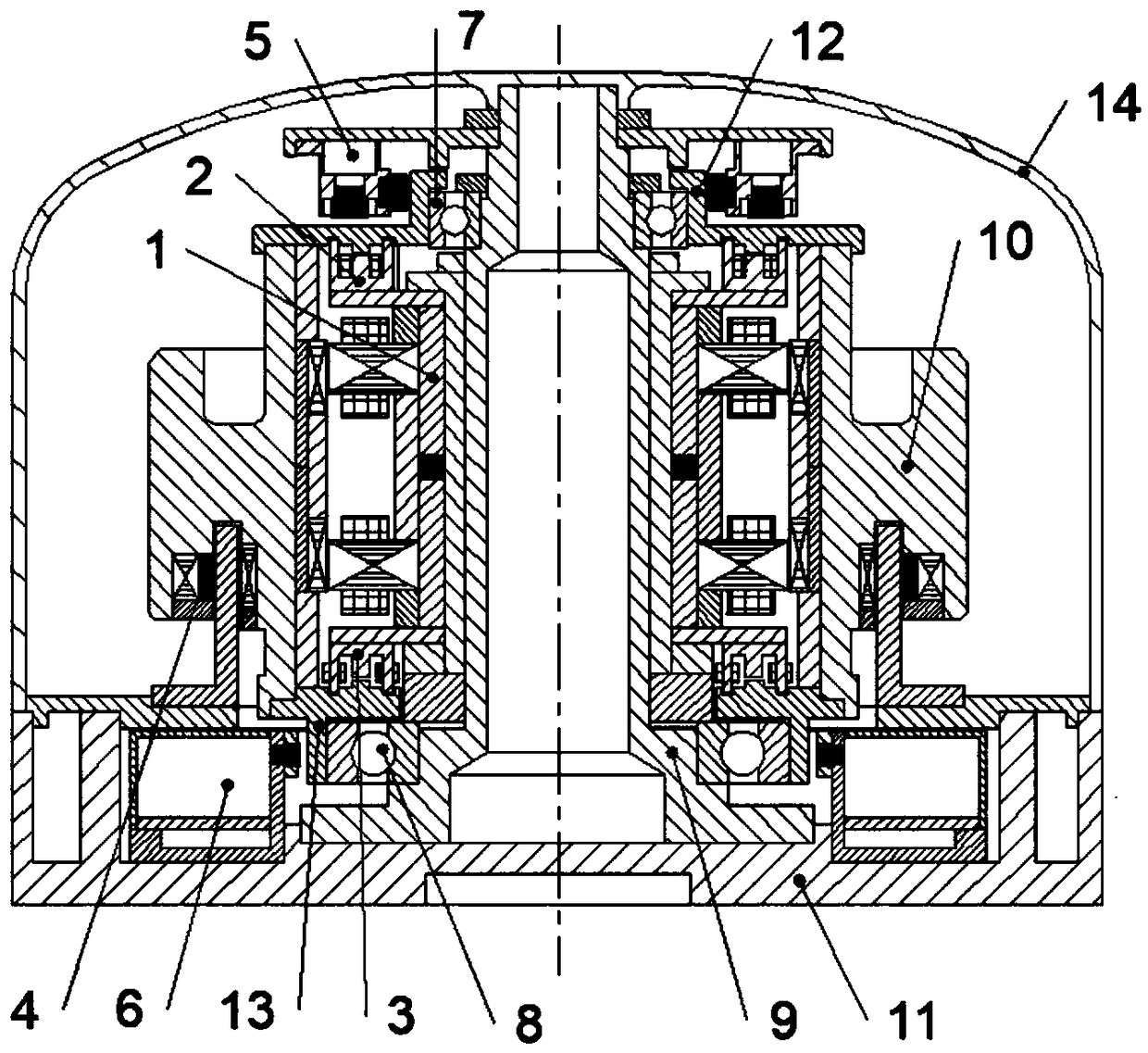

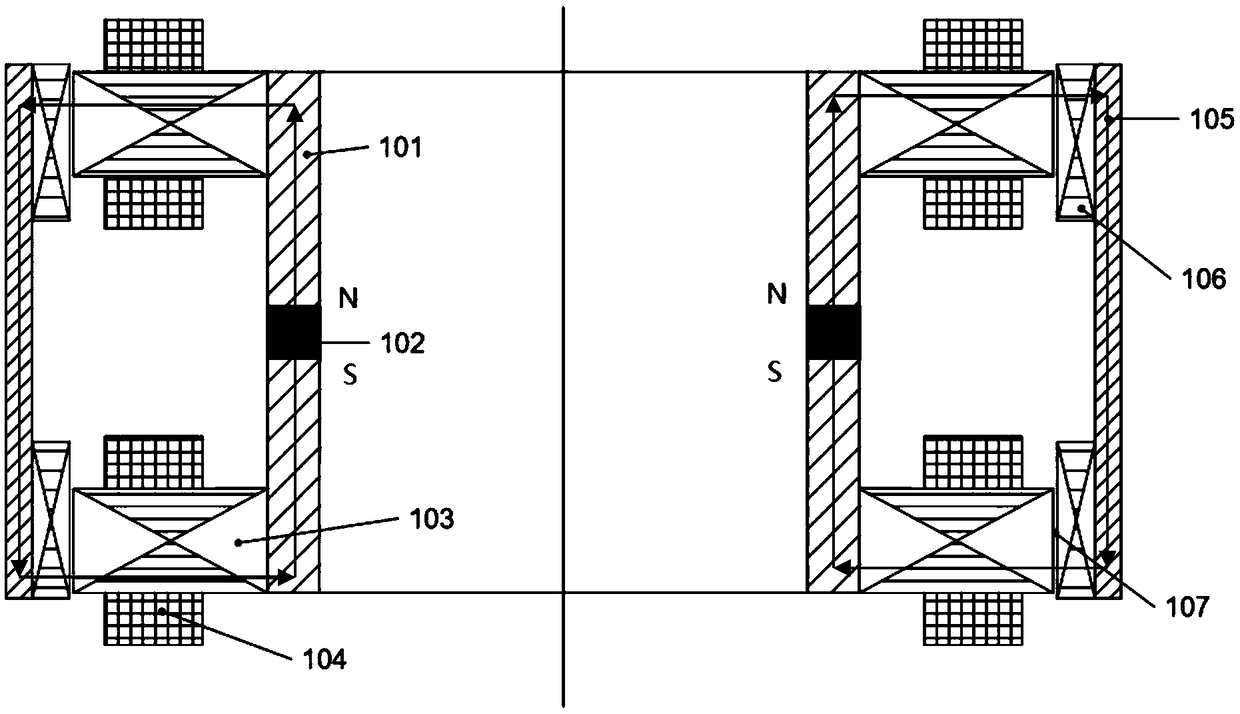

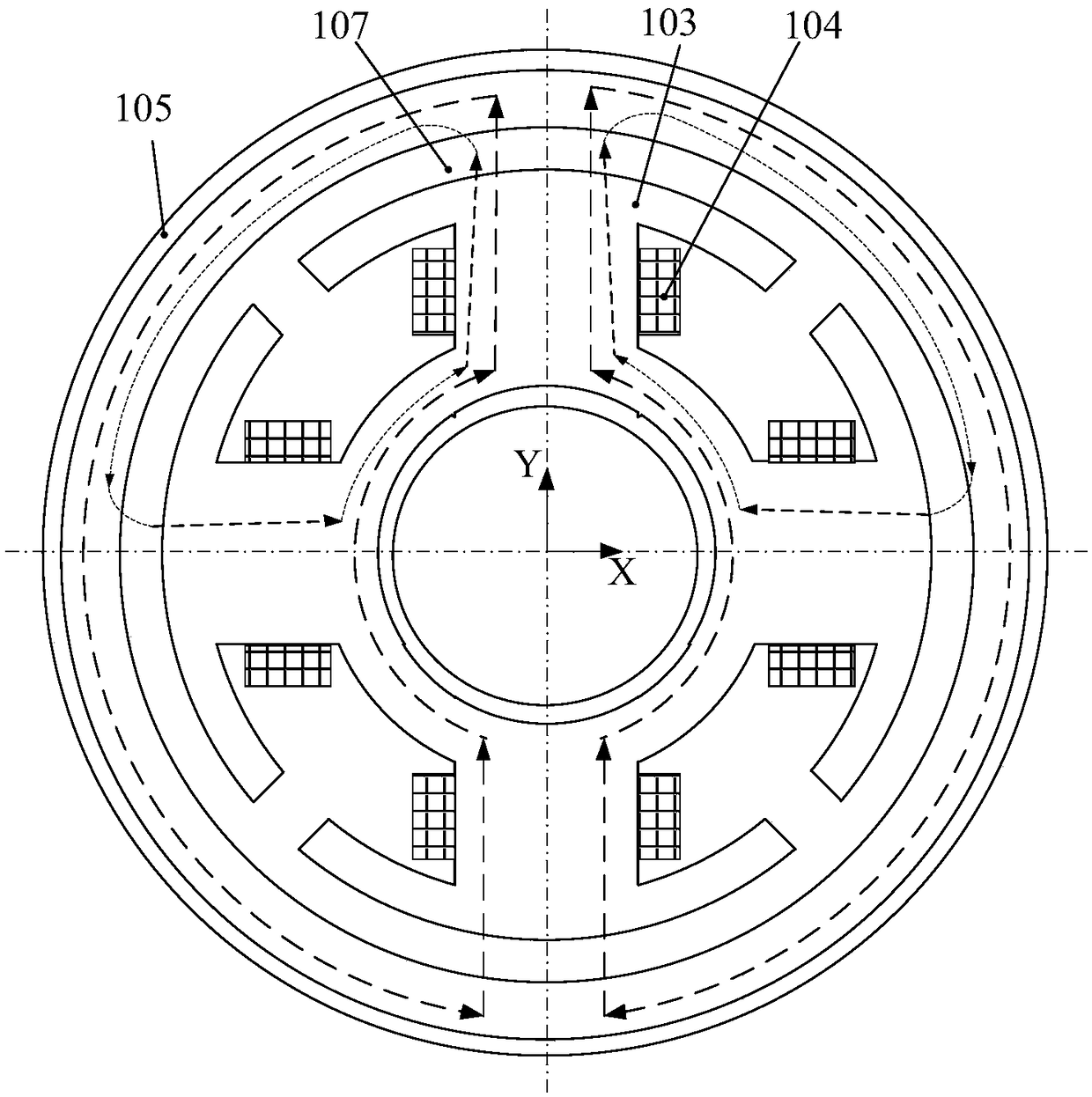

[0022] Such as figure 1 As shown, a five-degree-of-freedom magnetic levitation flywheel consists of a radial magnetic bearing (1), an upper axial magnetic bearing (2), a lower axial magnetic bearing (3), a high-speed motor (4), and a radial-axis integrated sensor ( 5), radial sensor (6), upper protective bearing (7), lower protective bearing (8), mandrel (9), wheel body (10), base (11), upper axial thrust plate (12), The lower axial thrust plate (13) and the housing (14) are composed of the mandrel (9) located in the center of the gyro room, the stator part of the radial magnetic bearing (1) is placed on the mandrel (9), and the radial The upper end of the stator part of the magnetic bearing (1) is the upper axial magnetic bearing (2). The upper axial magnetic bearing (2) is composed of eight axial magnetic bearing stator units. The upper end of the upper axial magnetic bearing (2) is the upper The protective bearing (7), the upper axial magnetic bearing (2) and the upper pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap