A kind of elastic pipeline hanger with damping type vibration reduction and impact resistance for ships

A pipe hanger and anti-shock technology, which is applied in the direction of pipe support, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of poor anti-shock performance, anti-shock design of pipeline system, development and layout of anti-shock components The pipeline system impact test acceptance and other standards and specifications are still blank and easy to be damaged, so as to achieve the effect of improving the medium and high frequency vibration reduction performance, compact structure and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

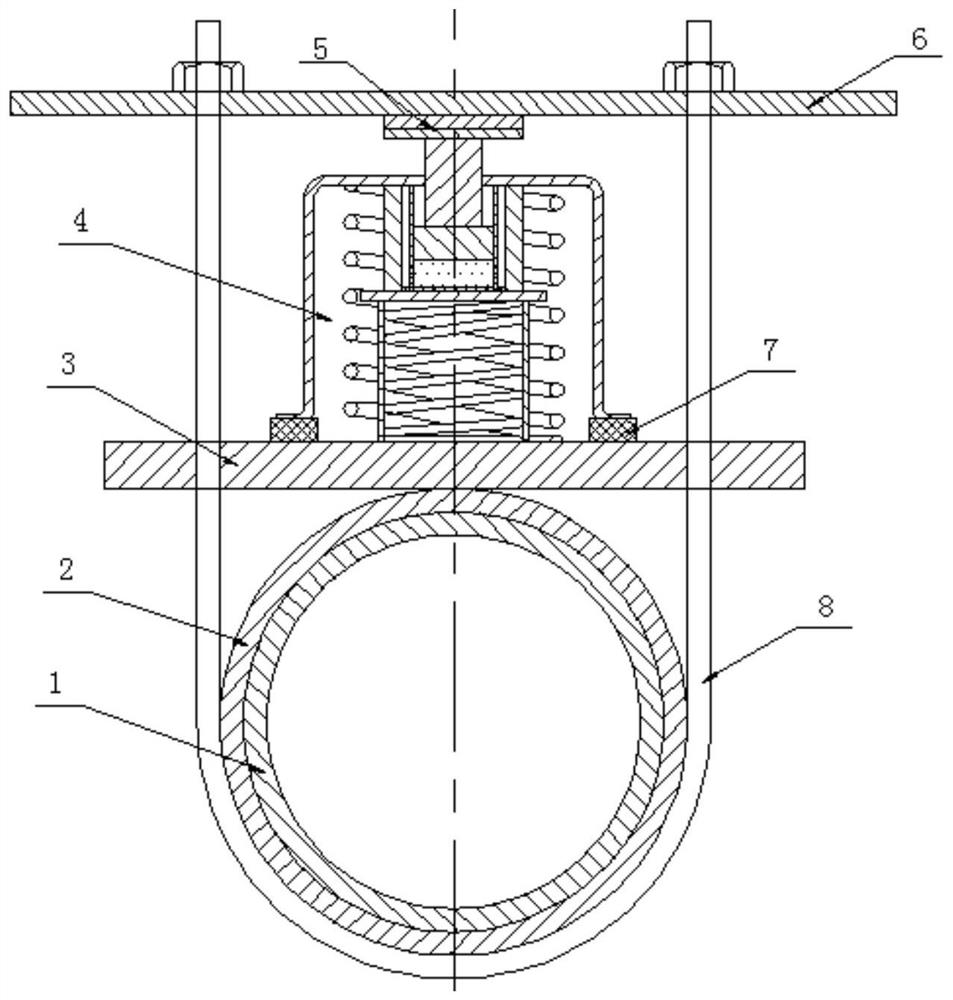

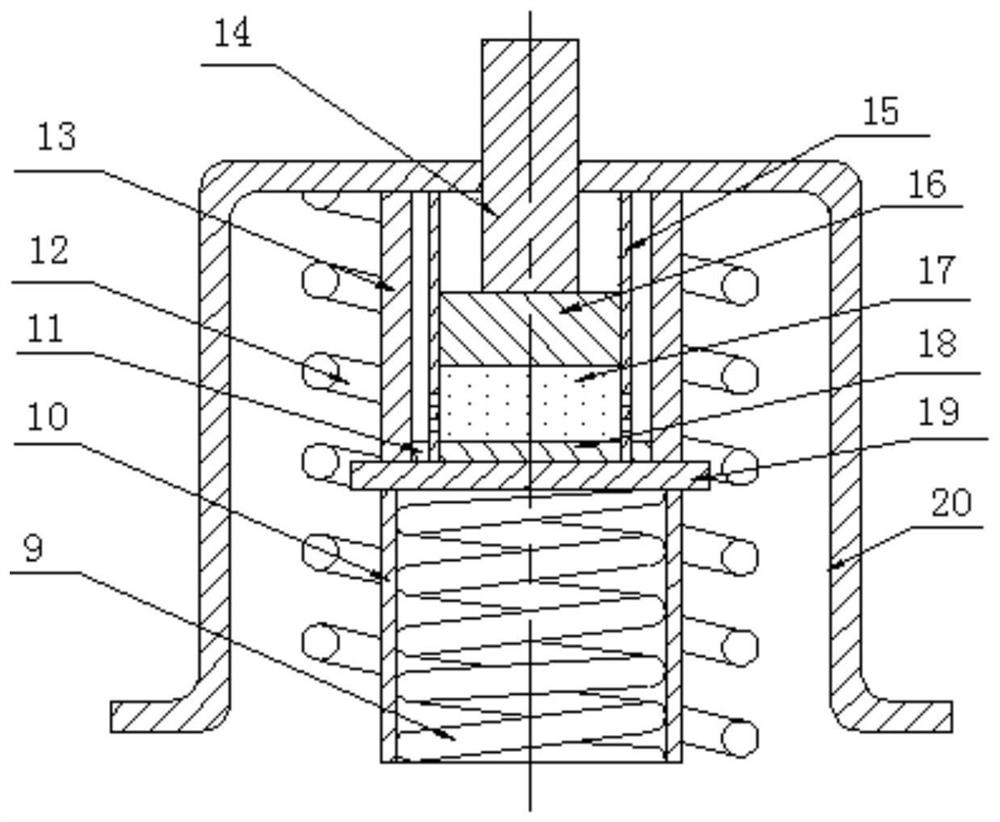

[0027] Implementation case 1: When the pipeline installation needs to be arranged in a suspended manner according to the space characteristics, such as figure 1 and figure 2 Shown, be a kind of pipeline hanger of the present invention for marine vibration damping and impact resistance, by pipeline 1, wire mesh washer 2, movable baffle 3, shock absorber 4, damping metal sticking board 5, non-slip rubber pad 7, pipe Card 8, bracket 6, small spring 9, elastic body 10, sealing ring 11, large spring 12, damping cylinder 13, piston rod 14, piston cylinder 15, damping piston 16, damping liquid 17, sealing ring 2 18, barrel Cover 19, shell 20 are formed.

[0028] A movable baffle 3 attached to the pipeline 1 is arranged between the pipeline 1 and the bracket 6 , and the other plane of the movable baffle 3 is provided with a shock absorber connected to the bracket 6 through a non-slip rubber pad 7 . A wire mesh gasket 2 is also arranged between the pipeline 1 and the pipe clip 8; th...

Embodiment example 2

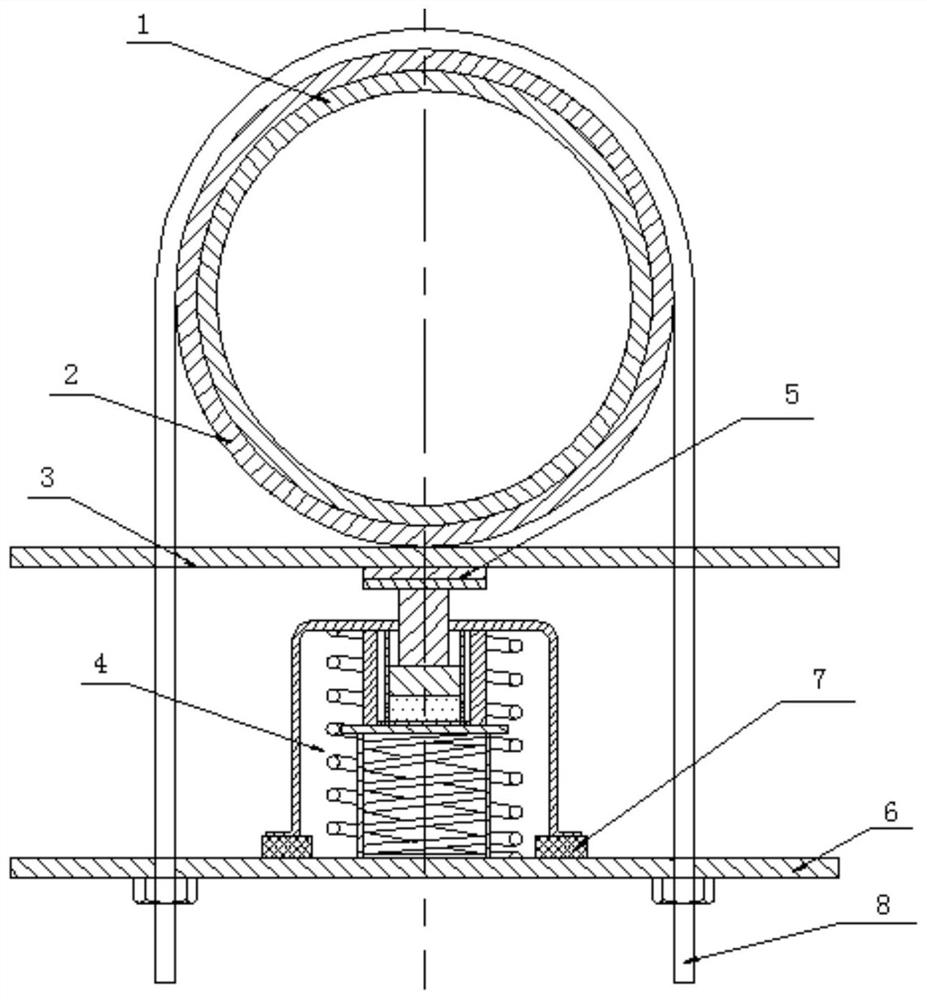

[0036] Implementation case 2: Large-diameter pipeline work is also required in the ship pipeline system due to working conditions, such as image 3 As shown, the implementation of the present invention relates to the installation method of large-diameter pipelines in the ship pipeline system. During work, the wire mesh gasket 2 wraps the pipeline 1 and places it on the plane of the movable baffle 3. On the other plane of the movable baffle 3, a shock absorber 4 connected to the bracket 6 is placed on the other plane of the movable baffle 3. Anti-slip rubber pad 7 is installed between 6 and shock absorber 4 to keep the balance and stability of shock absorber 4; when the pipeline vibrates, it passes through movable baffle 3 and is transmitted to piston rod 14, pushing damping piston 16 to compress damping fluid 17 , through the through hole at the lower end of the piston cylinder 15, it flows into the gap cavity between the piston cylinder 15 and the damping cylinder 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com