Measuring Method of Residual Stress Distribution of Composite Sheet Based on Incremental Cut Method

A composite material, residual stress technology, applied in the direction of force/torque/work measuring instrument, measuring force, measuring device, etc., can solve problems such as high cost, unfavorable engineering application, unsuitable detection, etc., to improve efficiency and reduce cutting times , the effect of improving scientificity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

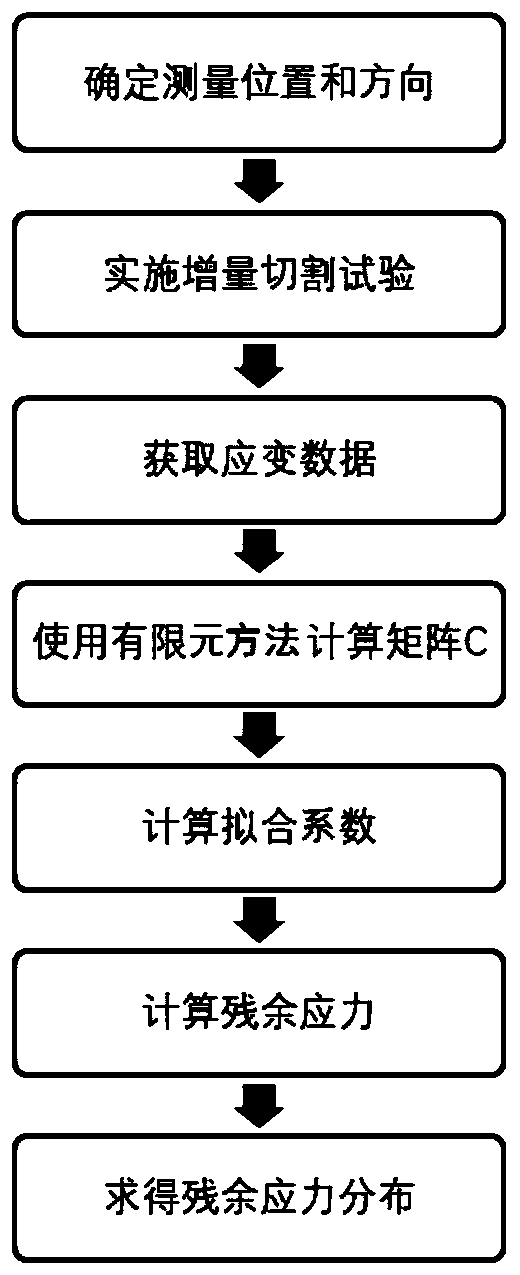

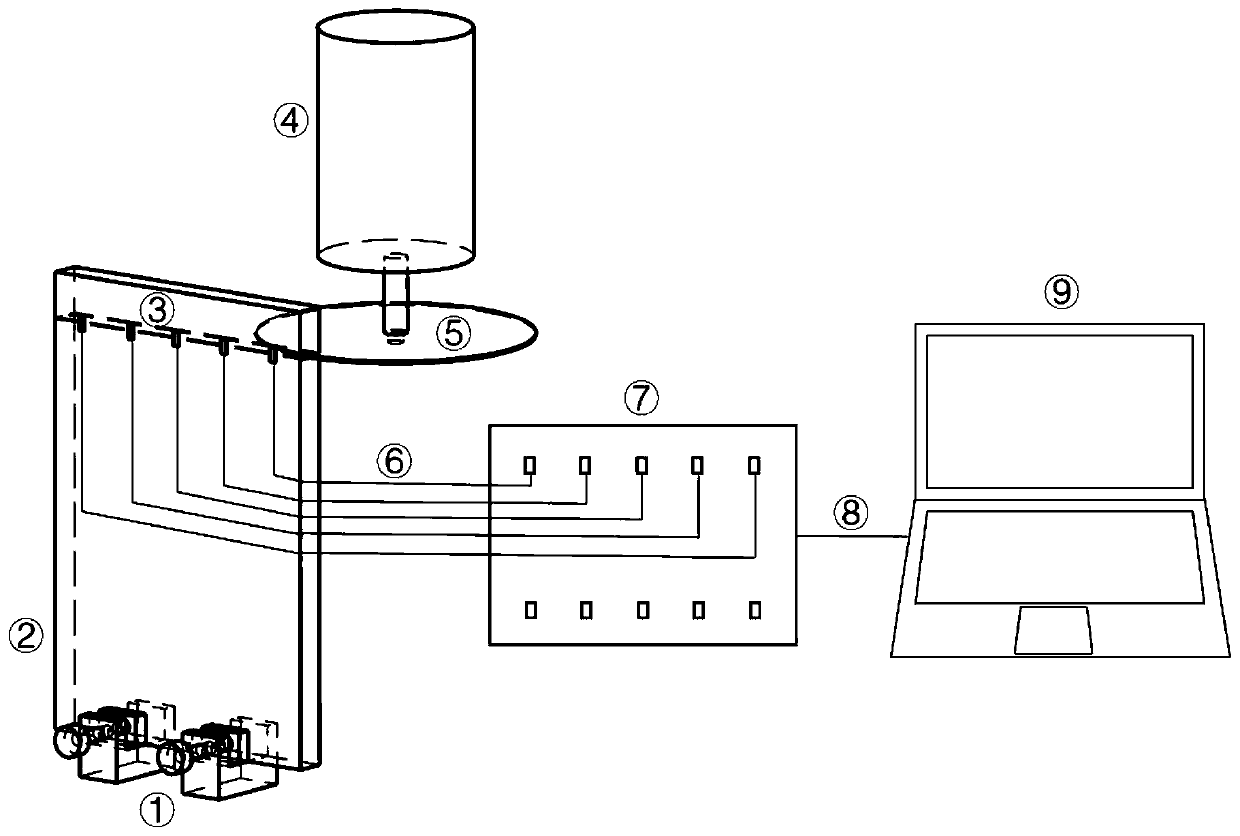

[0044] figure 1 It is a flowchart of the measurement and calculation of the residual stress of the composite material plate; image 3 is a schematic illustration of the residual stress measurement of a composite sheet based on the incremental cut method.

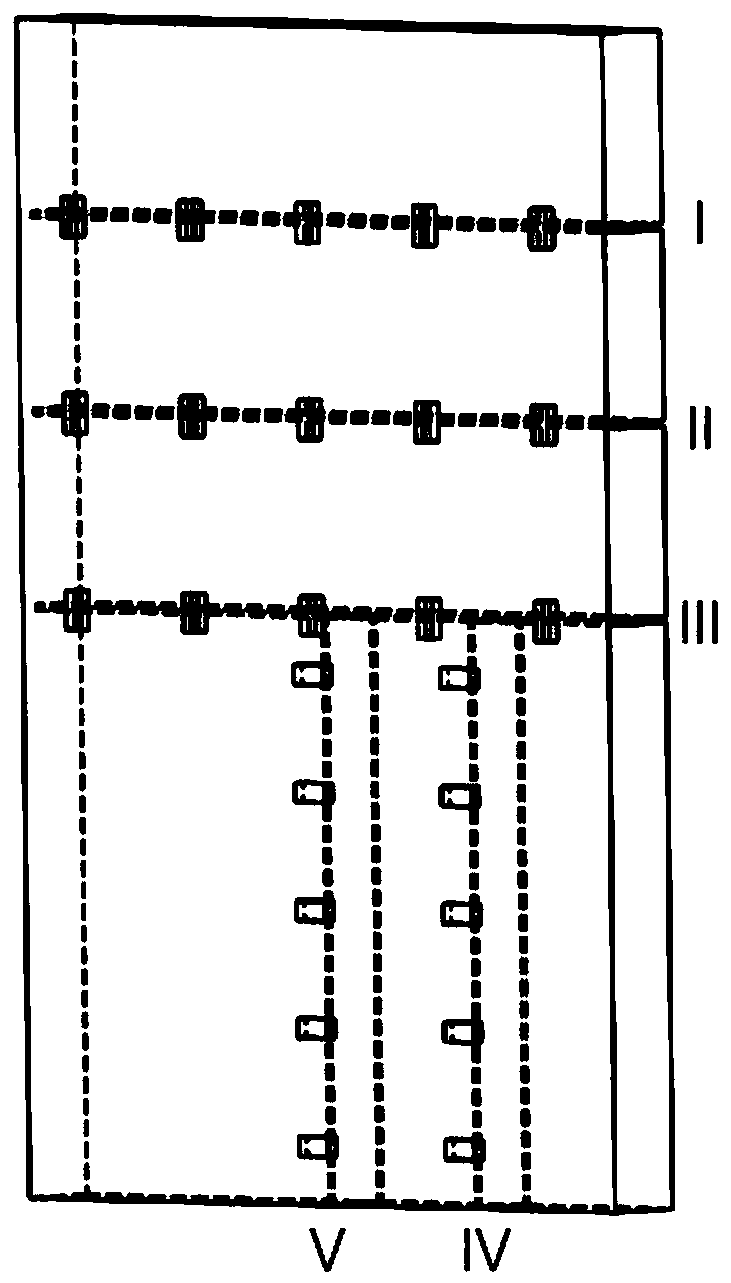

[0045] (1) determine the area to be measured and the direction of the composite material plate 2, figure 2 A common test scheme is shown, and five cutting positions Ⅰ-Ⅴ are determined. In addition, the cutting position and direction can be determined by oneself according to the needs.

[0046](2) Polish the first cutting position I in the area to be measured along the width direction with fine sandpaper until the surface is smooth, then clean the polished surface with acetone, wipe off the impurities on the surface, and paste several strain gauges 3 according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com