Open flash point measuring equipment

An open flash point and measuring device technology, which is applied in the field of open flash point measuring devices, can solve the problems of insufficient fuel combustion, insufficient fuel spraying, and inability to adjust the contact distance of the ignition mechanism, so as to achieve a good combustion effect and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

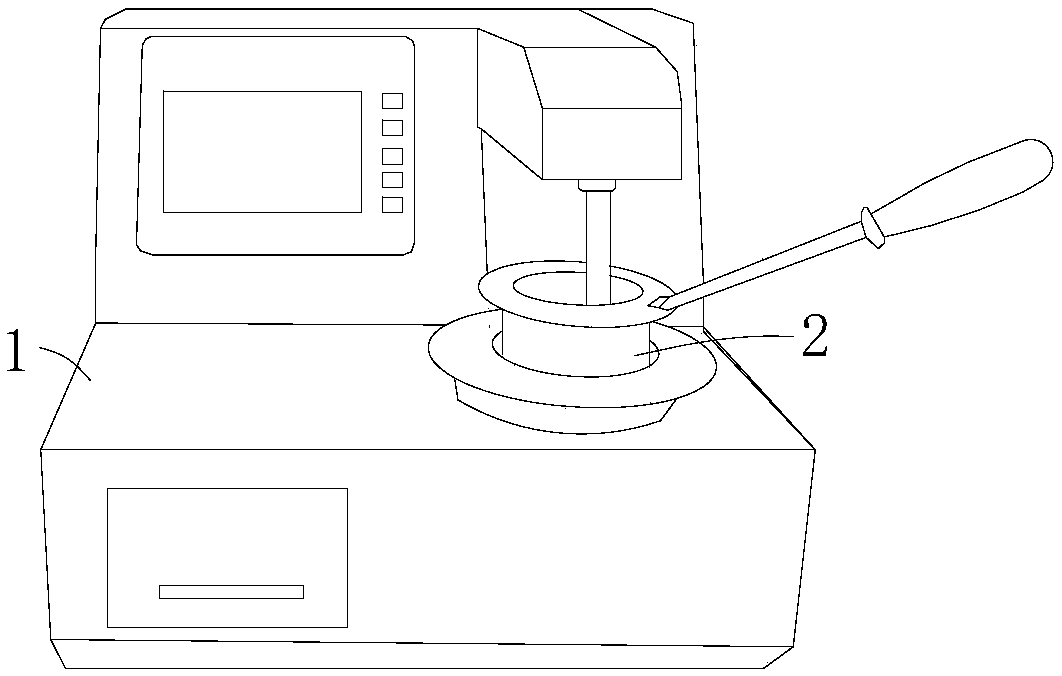

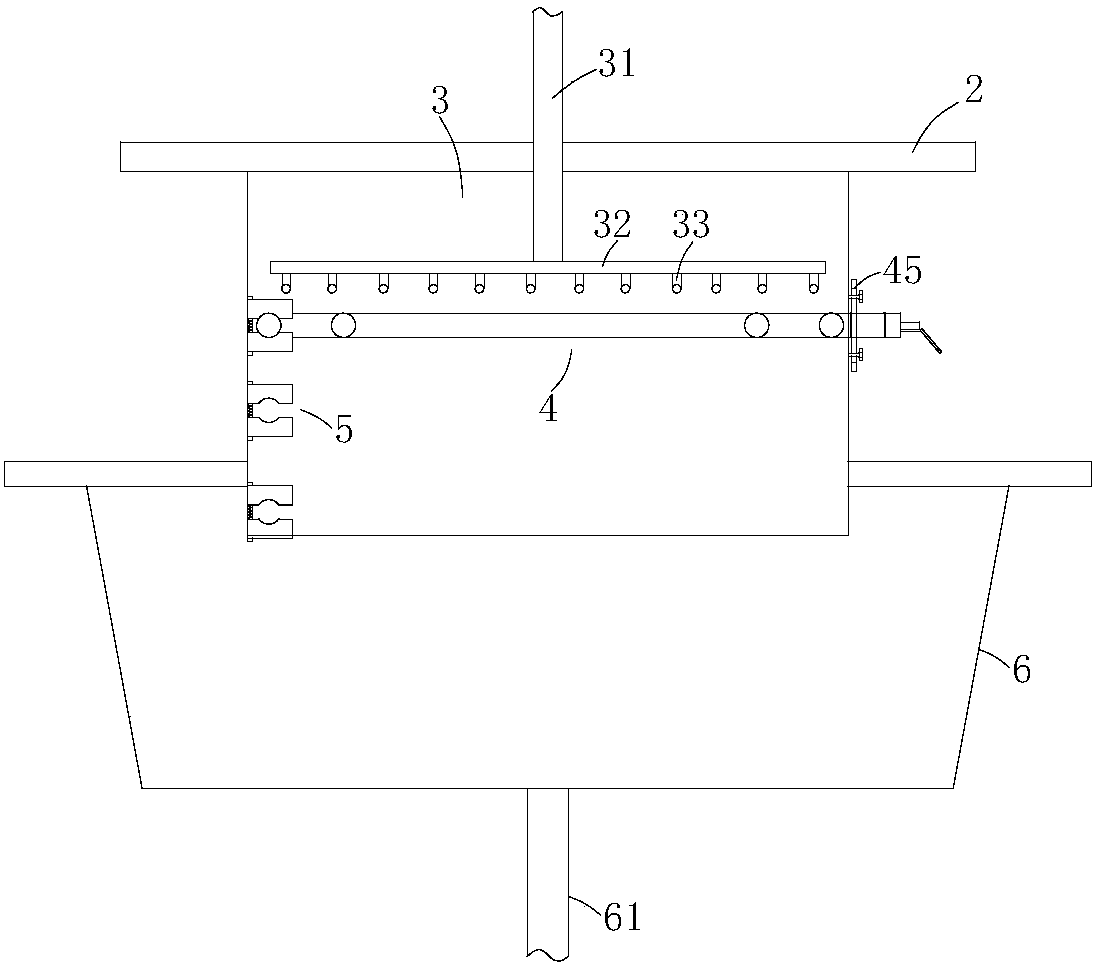

[0017] Such as Figure 1 to Figure 4 Shown, a kind of opening flash point tester comprises casing 1, is provided with flashover detection device on casing 1, and flashover detection device comprises flashover box 2, is provided with atomizing mechanism on the top of flashover box 2 3. There is an ignition mechanism 4 located below the atomization mechanism 3 in the flash box 2, and a plurality of fixing mechanisms 5 are arranged on the inner wall of the flash box 2, and the ignition mechanism 4 is fixed on the inner wall of the flash box 2 through the fixing mechanism 5 superior;

[0018] The atomizing mechanism 3 includes a liquid inlet pipe 31, the liquid inlet pipe 31 is connected to a spray plate 32, and a plurality of atomizing nozzles 33 are arranged on the spray plate 32, and the openings of the atomizing nozzles 33 face the ignition mechanism 4;

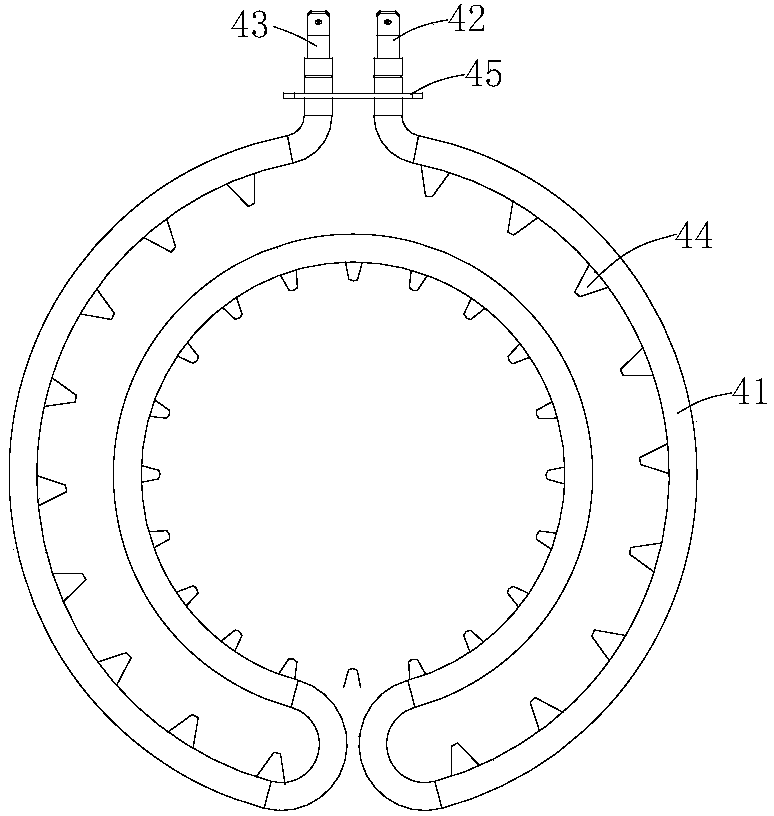

[0019] Ignition mechanism 4 comprises a plurality of circular detection rings 41, a plurality of circular detection rings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com