Method for predicting mechanical seal leakage failure of in-service rotating equipment

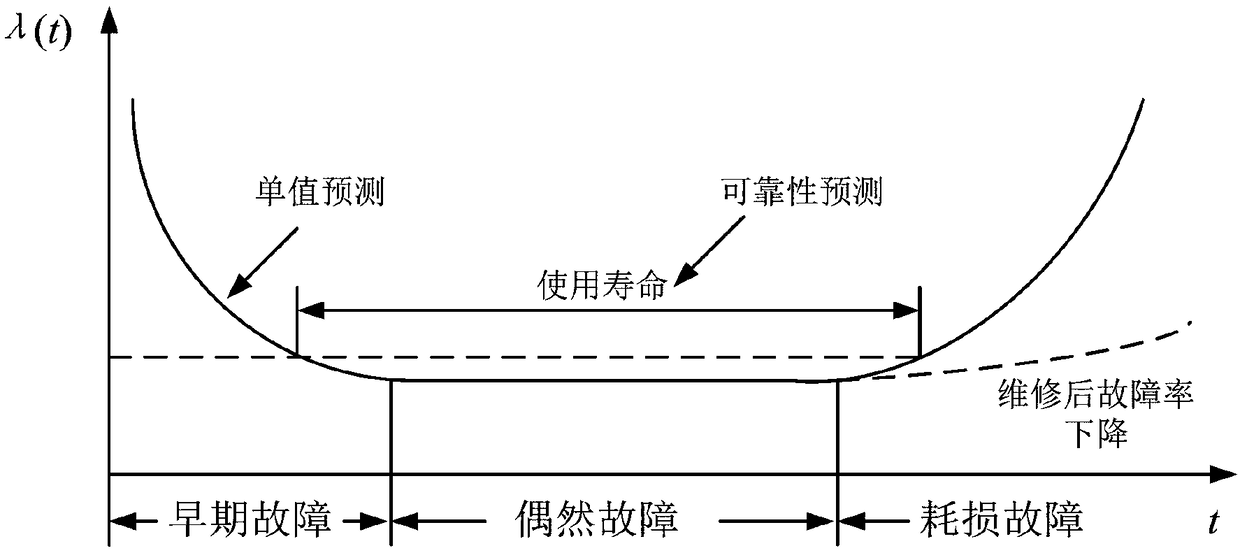

A technology for mechanical sealing and rotating equipment, applied in prediction, computer-aided design, design optimization/simulation, etc., can solve the problems of equipment not conforming to Weibull model distribution, single model, unable to adapt to different data samples, etc., and achieve leakage fault prediction The effect of improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

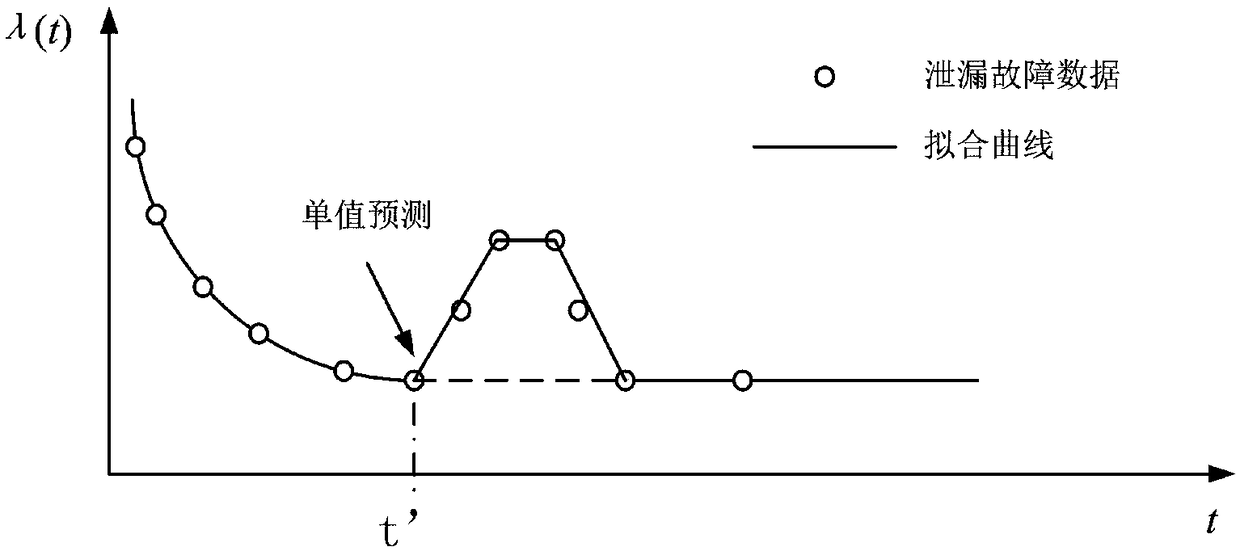

Problems solved by technology

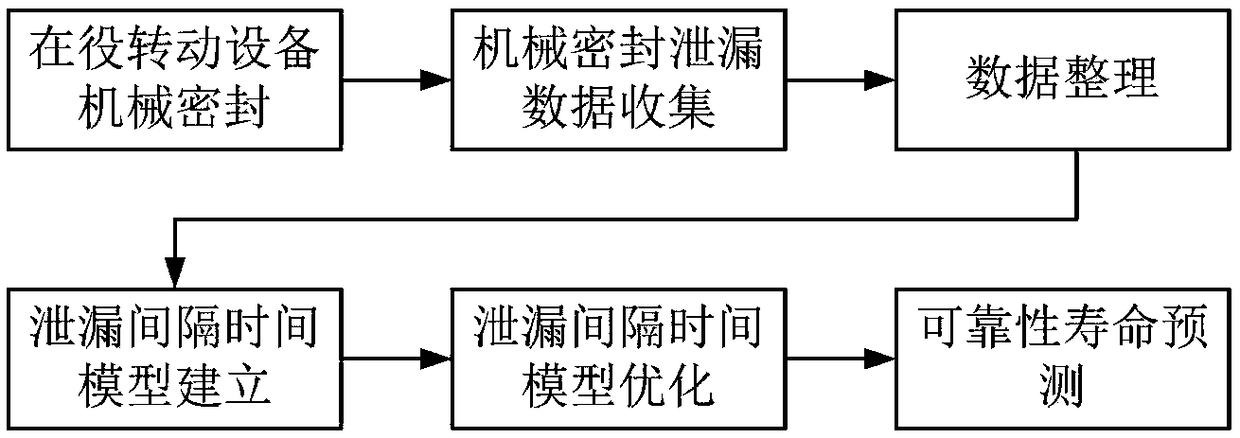

Method used

Image

Examples

specific example

[0111] The example of the present invention is based on the historical failure data of the mechanical seal of the high-temperature centrifugal pump to predict the time period of the leakage failure. The high-temperature centrifugal pump involved in the example has been operating stably for a period of time and has entered a period of accidental failure. Data-driven models can be used to predict. The details are as follows:

[0112] (1) Collection and collation of mechanical seal leakage failure data

[0113] A total of 33 mechanical seal leakage failure data of the high-temperature centrifugal pump since its operation have been collected. After sorting, as shown in Table 1, the operating time is the difference between the mechanical seal leakage failure time point and the operational time point. It is confirmed that all the fault types are related faults, and they must be included in the fault collection.

[0114] Table 1 Mechanical seal leakage failure data

[0115] Serial numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com