Electrically scanned X-ray tube

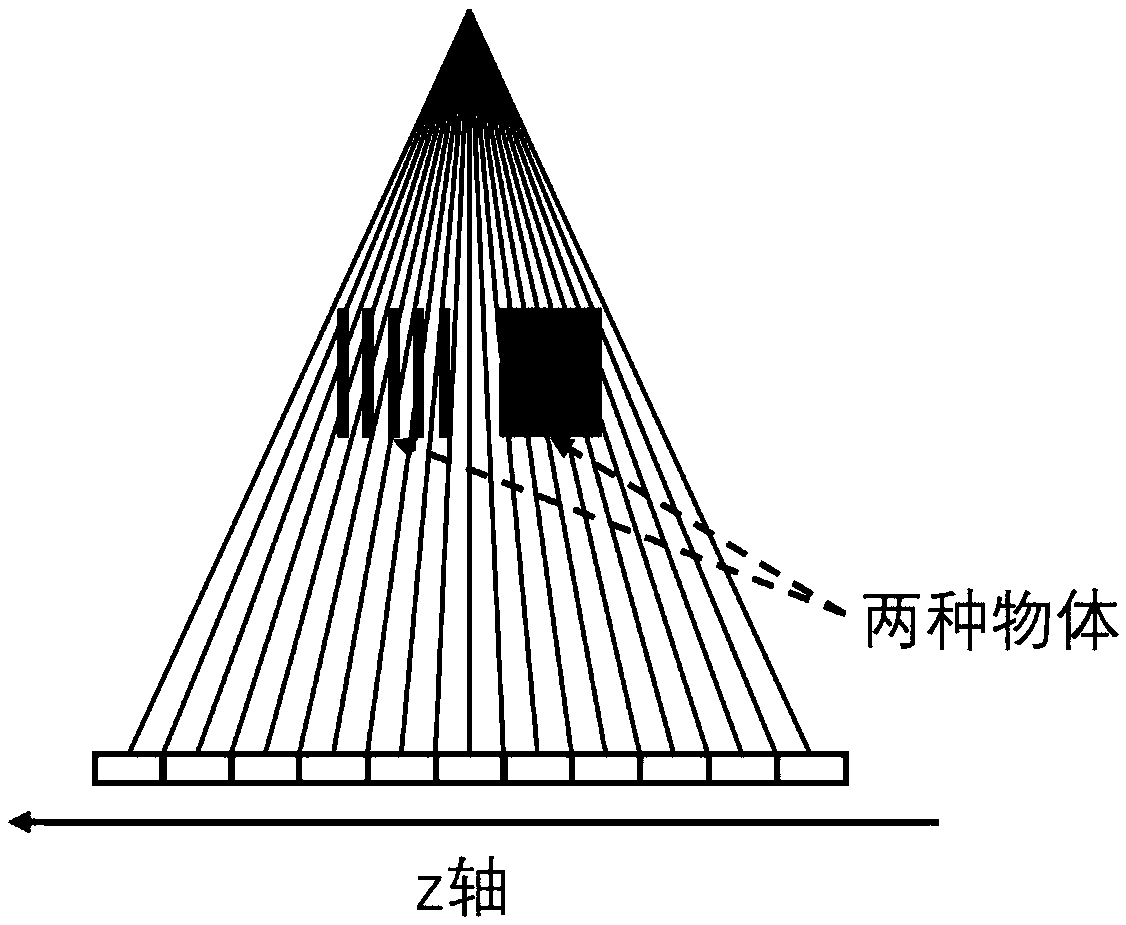

An X-ray tube and electronic scanning technology, applied in the field of X-ray tubes, can solve problems such as cone heart beam artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

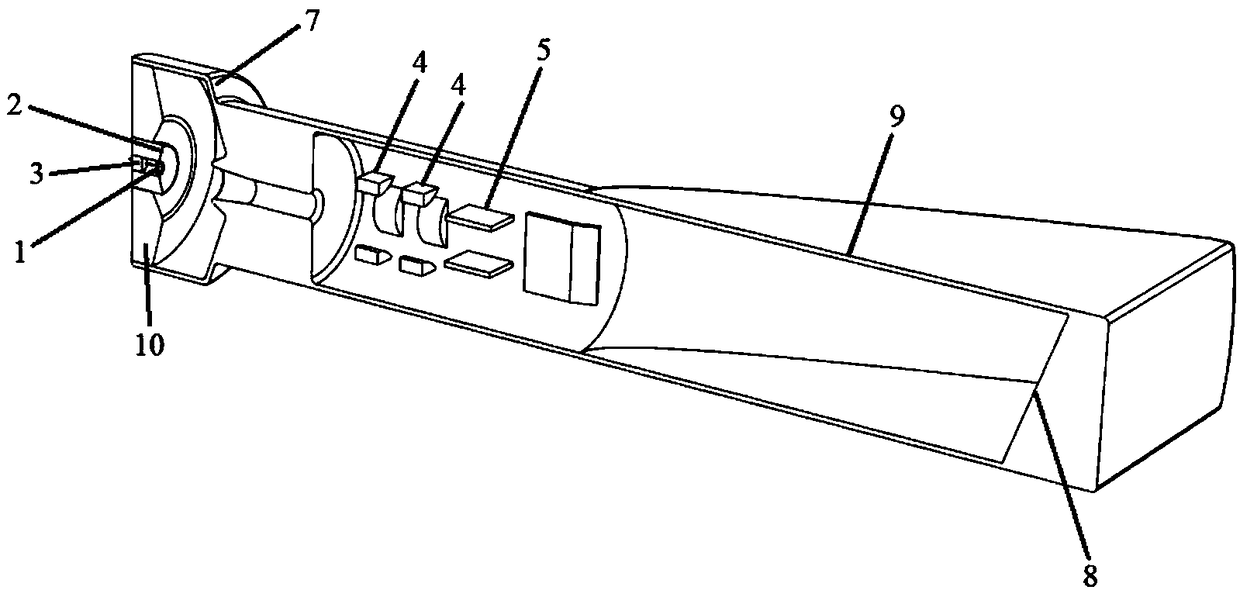

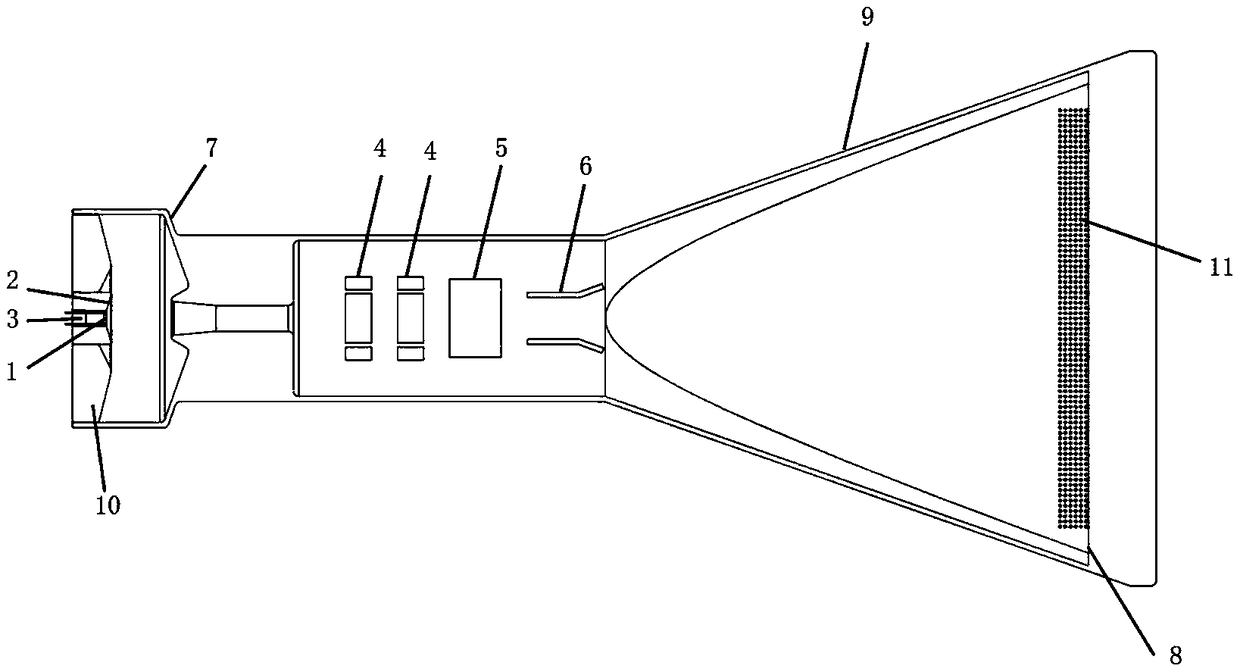

[0027] Embodiment 1 provides an electronically scanned X-ray tube, the structure of which is shown in FIG. 2( a ). The electronic scanning X-ray tube includes a cathode assembly, an electric focusing deflection assembly and an anode assembly. The cathode assembly is used to generate electron beams and pre-focus the electron beams; after the electron beams enter the drift channel, they are deflected and focused under the action of the electric focusing deflection assembly, and finally hit the target disk of the anode assembly, and emit X-rays.

[0028] Specifically, please refer to Figure 2(a) and Figure 2(b) at the same time, the cathode assembly includes an electron emission source 1, a focusing electrode 2 and an insulating ceramic 3; wherein the electron emission source 1 is located in the focusing electrode 2 , the electron beam emitted from the electron emission source 1 is initially focused by the focusing electric field generated by the focusing electrode. The pins of...

Embodiment 2

[0037] The second embodiment provides an electronic scanning X-ray tube, including a cathode assembly, an electric focusing deflection assembly and an anode assembly. The difference from the first embodiment is that in the second embodiment, the electric focus deflection assembly includes two electric quadrupole lenses 4 and a horizontal deflection assembly 6 . The first or second electric quadrupole lens can focus and vertically deflect the electron beam at the same time. On the basis of the original focusing voltage, an additional positive voltage is applied to the electrode 41, and an additional negative voltage is applied to the electrode 43, please refer to Figure 5 , forming an electric field in the direction indicated by the dotted arrow. The electron beam passing therethrough will be deflected toward the electrode 41 in the vertical direction. With the opposite voltage setting, the electron beam is deflected toward the electrode 42 . By replacing the vertical defle...

Embodiment 3

[0039] Embodiment 3 provides another electronic scanning X-ray tube, including a cathode assembly, an electric focus deflection assembly, and an anode assembly. The difference from the first embodiment is that in the third embodiment, the electric focus deflection assembly includes two electric quadrupole lenses 4 and a horizontal deflection assembly 6 . The electronically scanned X-ray tube provided in the third embodiment eliminates the vertical deflection component, so as to realize the electronically scanned linear X-ray tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com