System for improving operation and maintenance efficiency of automatic system

An automated system, operation and maintenance efficiency technology, applied in information technology support systems, electrical components, circuit devices, etc., can solve problems such as inability to accurately determine the cause of failure and eliminate failures, differences in the technical level of attendants, and inability to detect problems in advance. Achieve the effect of shortening the processing time of network channel faults, improving the processing of network channel fault accidents, and shortening the processing time of system faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1: The following combination figure 1 — Figure 11 The present invention will be described in detail.

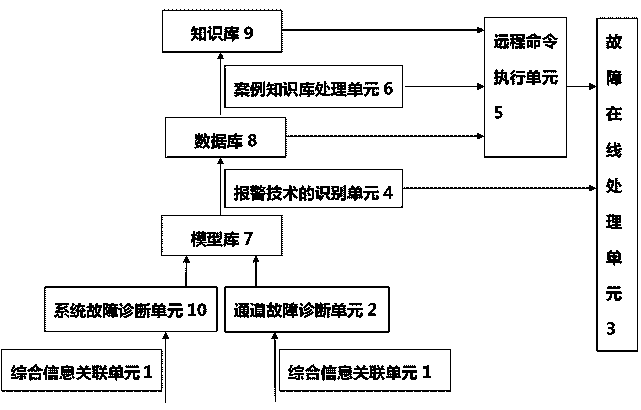

[0068] The components or units of this system are:

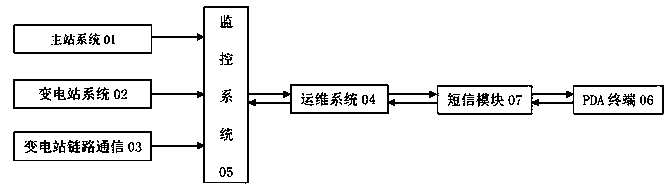

[0069] Master station system 01, substation system 02, substation link communication 03, operation and maintenance system 04, monitoring system 05, PDA terminal 06, SMS module 07;

[0070] Comprehensive information association unit 1, channel fault diagnosis unit 2, fault online processing unit 3, alarm technology identification unit 4, remote command execution unit 5, case knowledge base processing unit 6, model base 7, database 8, knowledge base 9, system Fault diagnosis unit 10;

[0071] The monitoring system 05 is connected with the main station system 01, the substation system 02 and the substation link communication 03 for monitoring, the operation and maintenance system 04 is connected with the monitoring system 05 for data interaction, the SMS module 07 is connected with the operation and maintena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com