Planting auxiliary device for vegetable greenhouse

A technology of vegetable greenhouses and auxiliary devices, which is applied in the directions of application, planting methods, excavation/covering ditches, etc., can solve the problems of high labor intensity, low production efficiency, and inapplicability, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

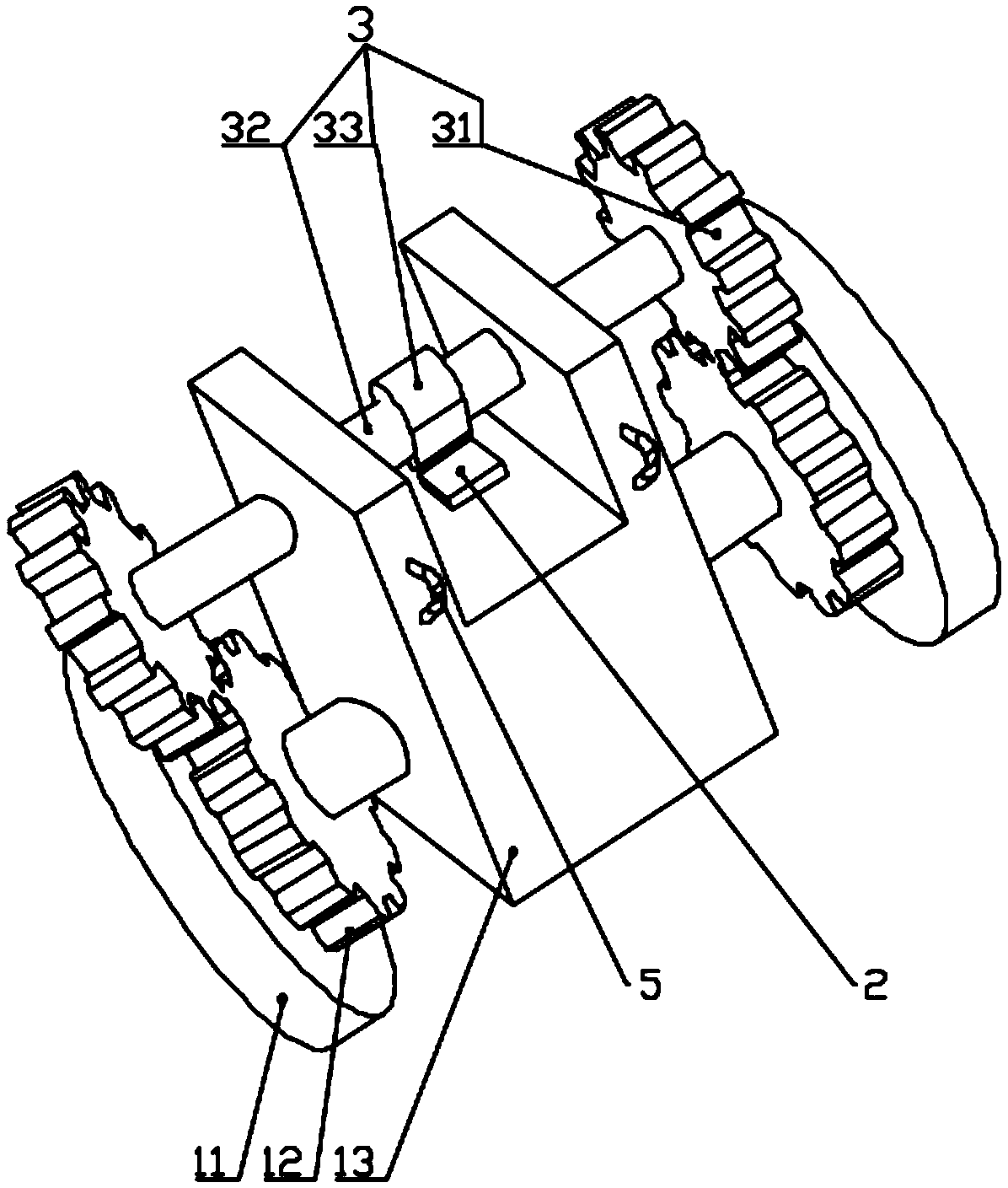

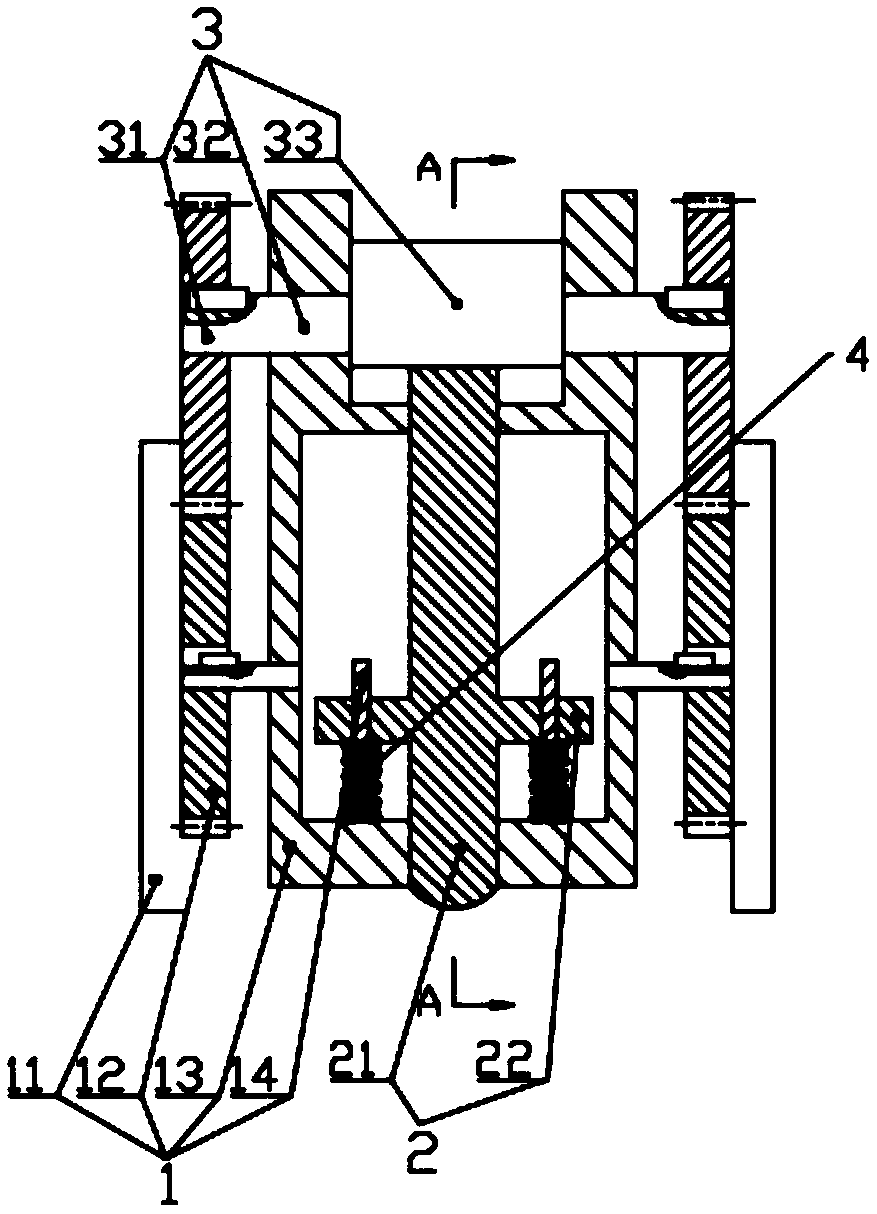

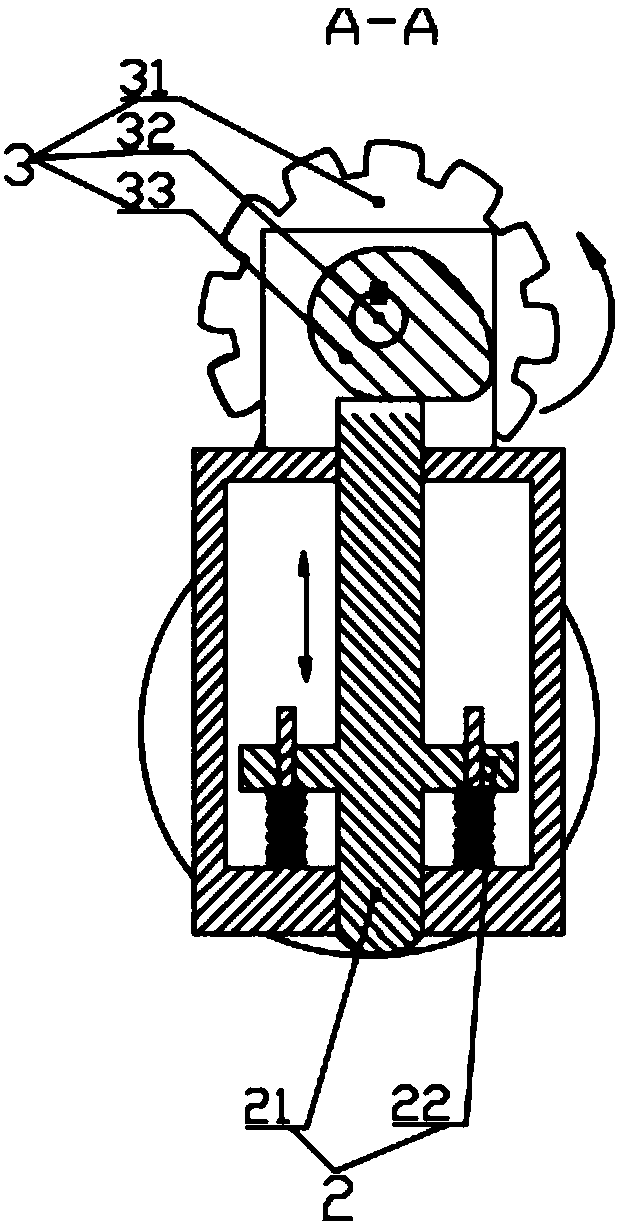

[0021] Figure 1 ~ Figure 3 Is a preferred embodiment of the present invention:

[0022] Such as figure 1 and figure 2 As shown, a planting aid for vegetable greenhouses includes a sowing vehicle 1 and a return spring 4. The sowing vehicle 1 includes a roller 11, a first wheel 12, a seeding cavity 13 and a spring post 14; the roller 11 is provided with a roller shaft, so The first wheel 12 is located behind the roller 11 and is connected with the roller shaft key. Both sides of the sowing chamber 13 are symmetrically provided with roller shaft holes, and the rollers 11 are symmetrically arranged on both sides of the sowing chamber 13. The rollers The 11 shaft is in clearance fit with the roller shaft hole, the sowing cavity 13 is provided with a containing cavity, the spring column 14 is arranged on the bottom surface of the containing cavity and is integrated with the sowing cavity 13, and the return spring 4 is sleeved on the spring column 14, and the bottom surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com