Shallow skinning machine for fishes

A peeling machine and fish technology, applied in fish skin removal, fish processing, slaughtering, etc., can solve problems such as slipping, achieve the effects of ensuring continuous production, preventing slipping, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

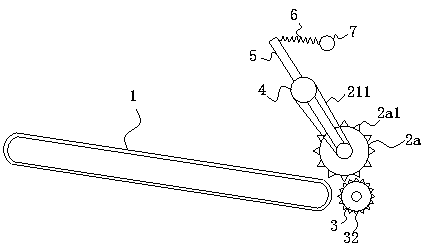

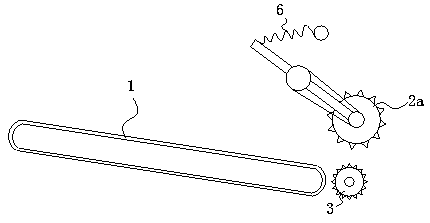

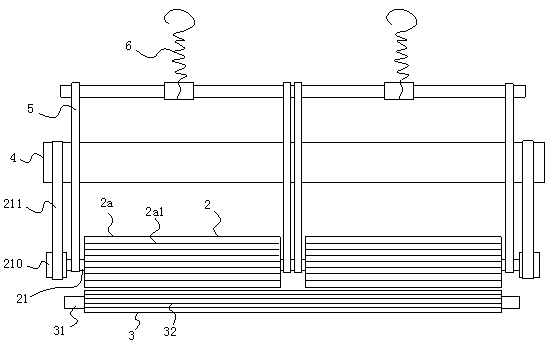

[0014] Such as figure 1 , 2 , 3, the fish shallow peeling machine of the present invention, comprises the feeding belt 1 that is provided with inclination, the bottom of feeding belt 1 is provided with feeding roller 2 and cutter roller 3, and the transmission shaft 21 of feeding roller 2 and cutter roller The rotating shaft 31 of 3 is arranged in parallel, and the rotating shaft 21 of feeding roller 2 is coaxially provided with a plurality of feeding rollers 2a along the shaft length direction, and the two ends of the transmission shaft 21 of feeding roller 2 are driving wheels 210, and driving wheels 210 pass transmission belt 211 Be connected with drive shaft 4, the transmission shaft part of the two ends of feeding roller 2a is hinged with the lower end of movable support 5, and movable support 5 is the frame-shaped support that obliquely arranges, and the middle part of movable support 5 is hinged with drive shaft 4, and the movable support 5 The upper end is connected w...

Embodiment 2

[0018] Such as Figure 4 , different from embodiment 1, the diameter of the roller surface of the feeding roller 2a gradually decreases from the two ends to the center, which can increase the contact area between the feeding teeth and the fish block surface of the roller surface of the feeding roller 2a, further Prevent fish blocks from slipping and ensure continuous production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com