Antibacterial glove for hemodialysis care and preparation method thereof

A hemodialysis and glove technology, applied in gloves, applications, protective clothing, etc., can solve the problems of poor antibacterial and anti-infection performance, insufficient tear resistance, allergic reactions, etc. The effect of good practicability and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

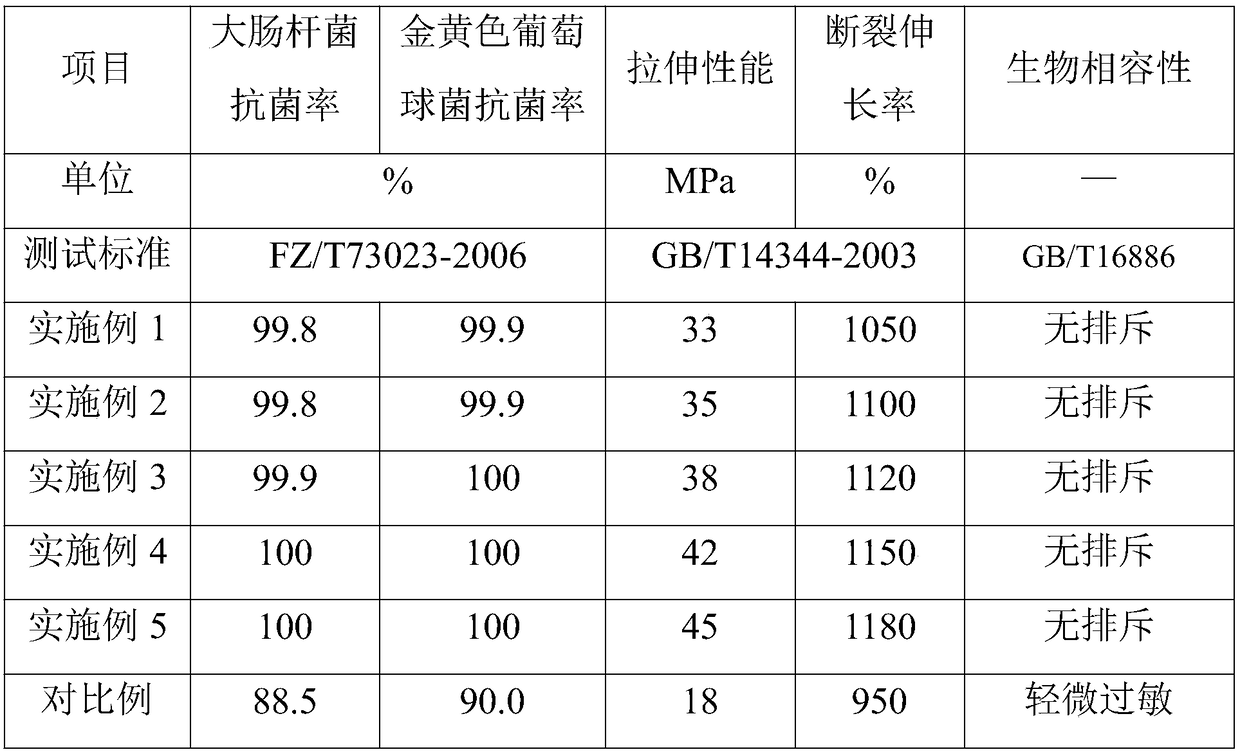

Examples

Embodiment 1

[0029] A preparation method of antibacterial gloves for hemodialysis care, comprising the steps of:

[0030] Ⅰ Preparation of polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide: Add 1kg of thiadioic acid and 1.22kg of 1,2-diamino-5-trifluoromethylbenzimidazole Add 0.4 kg of dicyclohexylcarbodiimide, 0.3 kg of 4-dimethylaminopyridine and 0.1 kg of tetrabutylammonium bromide to 10 kg of dimethyl sulfoxide, and stir and react at 90 ° C for 2 hours under a nitrogen atmosphere , then stirred and reacted at 125°C for 8 hours. After the reaction, it was precipitated in water, washed with ethanol for 3 times, and then dried to a constant weight at 80°C in a vacuum oven to obtain polythiadioic acid 1, 2-Diamino-5-trifluoromethyl benzimidazolamide;

[0031] II Glove molding: Grind 0.5kg of chlorosulfonated polyethylene into powder in a ball mill, and then add 1kg of polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide prepared through step I , and then ...

Embodiment 2

[0036] A preparation method of antibacterial gloves for hemodialysis care, comprising the steps of:

[0037] Ⅰ Preparation of polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide: Add 1kg of thiadioic acid and 1.22kg of 1,2-diamino-5-trifluoromethylbenzimidazole Add 0.45kg of dicyclohexylcarbodiimide, 0.3kg of 4-dimethylaminopyridine and 0.1kg of tetrabutylammonium bromide to 11kg of N,N-dimethylformamide, Stir the reaction at 95°C for 2.3 hours, and then stir the reaction at 127°C for 8.5 hours. After the reaction, it precipitates in water, washes the precipitated product with ethanol for 4 times, and then places it in a vacuum drying oven at 83°C to dry to constant weight. Polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide;

[0038] II Glove molding: Grind 0.5kg of chlorosulfonated polyethylene into powder in a ball mill, and then add polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide 1.1 kg, then the mixture is added to the...

Embodiment 3

[0043] A preparation method of antibacterial gloves for hemodialysis care, comprising the steps of:

[0044] Ⅰ Preparation of polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide: Add 1kg of thiadioic acid and 1.22kg of 1,2-diamino-5-trifluoromethylbenzimidazole Add 0.5kg of dicyclohexylcarbodiimide, 0.3kg of 4-dimethylaminopyridine and 0.1kg of tetrabutylammonium bromide to 13kg of N-methylpyrrolidone, and stir the reaction at 100°C under a neon atmosphere 2.5 hours, then stirred and reacted at 130°C for 9 hours. After the reaction, it was precipitated in water, washed with ethanol for 4 times, and then dried in a vacuum oven at 85°C to constant weight to obtain polythiadiic acid 1,2-Diamino-5-trifluoromethyl benzimidazolamide;

[0045] II Glove molding: Grind 0.5 kg of chlorosulfonated polyethylene into powder in a ball mill, and then add polythiadioic acid 1,2-diamino-5-trifluoromethylbenzimidazole amide 1.3 prepared through step I kg, and then the mixture ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap