Method for painting surface of metal guardrail

A guardrail and brushing technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. Smooth surface and tight bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

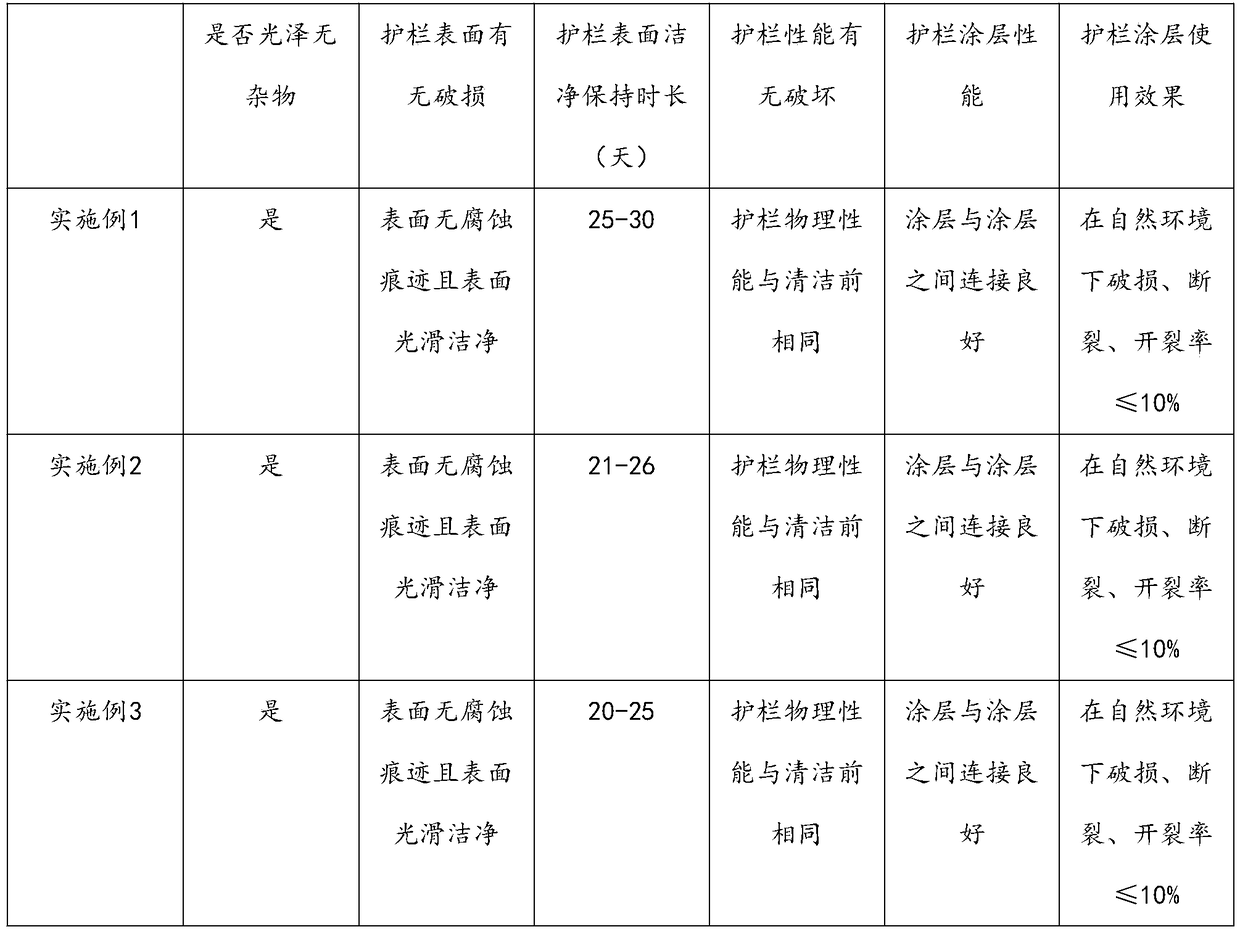

Examples

Embodiment 1

[0032] A method for brushing the surface of a metal guardrail, characterized in that: comprising the following steps,

[0033] Step 1. Rinse: Rinse the surface of the guardrail with clean water, then dry it with a cotton cloth and blow it with a medium-pressure blower for 7-11 minutes;

[0034] Step 2. Soaking: Use the soaking liquid to soak and clean the guardrail. The soaking liquid covers the guardrail for 25-30 minutes, then take it out, dry it with cotton cloth, and blow it with a medium-pressure blower for 7-11 minutes;

[0035] Step 3: Brushing:

[0036] ⅠStand up the guardrail, then paint it evenly, then paint a layer, polish it after drying, and then soak it in the soaking liquid for 10-15 minutes;

[0037] Ⅱ After soaking, take it out, wait for the surface liquid to dry naturally, then lightly polish it with sandpaper, and polish the uneven place;

[0038] Ⅲ After grinding, use a medium-pressure blower to blow air for 3-6 minutes, and then only need to apply the co...

Embodiment 2

[0050] A method for brushing the surface of a metal guardrail, characterized in that: comprising the following steps,

[0051] Step 1. Rinse: Rinse the surface of the guardrail with clean water, then dry it with a cotton cloth and blow it with a medium-pressure blower for 7-11 minutes;

[0052] Step 2. Soaking: Use the soaking liquid to soak and clean the guardrail. The soaking liquid covers the guardrail for 25-30 minutes, then take it out, dry it with cotton cloth, and blow it with a medium-pressure blower for 7-11 minutes;

[0053] Step 3: Brushing:

[0054] ⅠStand up the guardrail, then paint it evenly, then paint a layer, polish it after drying, and then soak it in the soaking liquid for 10-15 minutes;

[0055] Ⅱ After soaking, take it out, wait for the surface liquid to dry naturally, then lightly polish it with sandpaper, and polish the uneven place;

[0056] Ⅲ After grinding, use a medium-pressure blower to blow air for 3-6 minutes, and then only need to apply the co...

Embodiment 3

[0065] A method for brushing the surface of a metal guardrail, characterized in that: comprising the following steps,

[0066] Step 1. Rinse: Rinse the surface of the guardrail with clean water, then dry it with a cotton cloth and blow it with a medium-pressure blower for 7-11 minutes;

[0067] Step 2. Soak: Use the soaking liquid to soak and clean the guardrail. The soaking liquid covers the guardrail for 25-30 minutes, then take it out, dry it with cotton cloth, and blow it with a medium-pressure blower for 7-11 minutes;

[0068] Step 3: Brushing:

[0069] ⅠStand up the guardrail, then paint it evenly, then paint a layer, polish it after drying, and then soak it in the soaking solution for 10-15 minutes;

[0070] Ⅱ After soaking, take it out, wait for the surface liquid to dry naturally, then lightly polish it with sandpaper, and polish the uneven place;

[0071] Ⅲ After grinding, use a medium-pressure blower to blow air for 3-6 minutes, and then only need to apply the coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com