Inductive component pressure riveting device and inductive component automatic assembly equipment

A technology of inductance components and automatic assembly, which is applied in electrical components, inductance/transformer/magnet manufacturing, feeding devices, etc. The effect of high precision and yield, improved yield, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Combine below Figure 1-Figure 15 The present invention is further described.

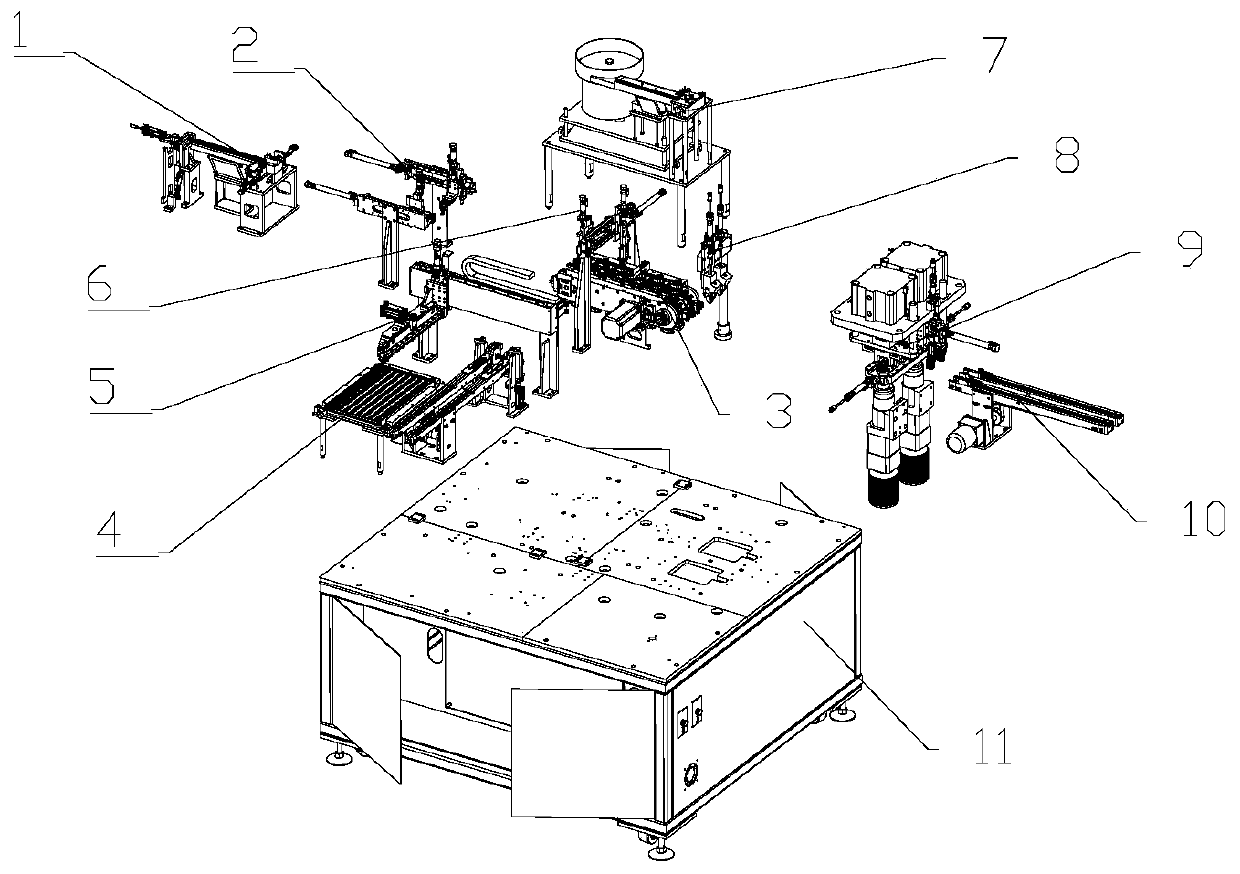

[0028] Such as Figure 1-Figure 15 The shown automatic assembly equipment for inductive elements includes a frame 14 and a shrapnel feeding device 1 on it, a first transfer manipulator device 2, a jig delivery device 3, a coil body feeding device 4, a second transfer manipulator device 5, The third transport manipulator device 6 , iron core feeding device 7 , iron core loading device 8 , inductive element pressing device 9 and finished product discharging device 10 .

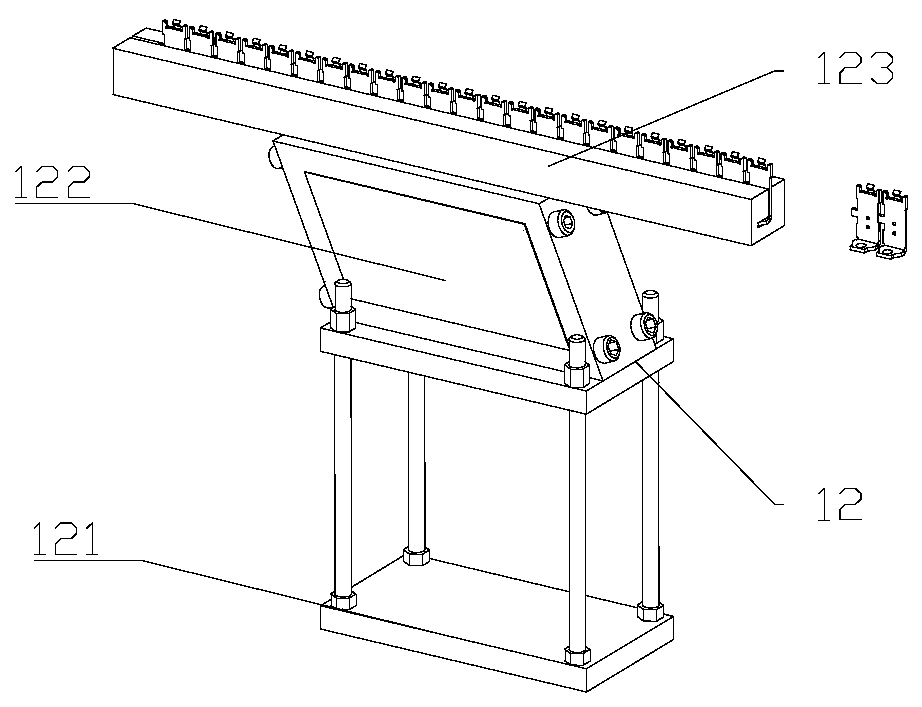

[0029] The inductor is mainly assembled by shrapnel a, coil body b and iron core d, and the feeding sequence is shrapnel a, coil body b and iron core d.

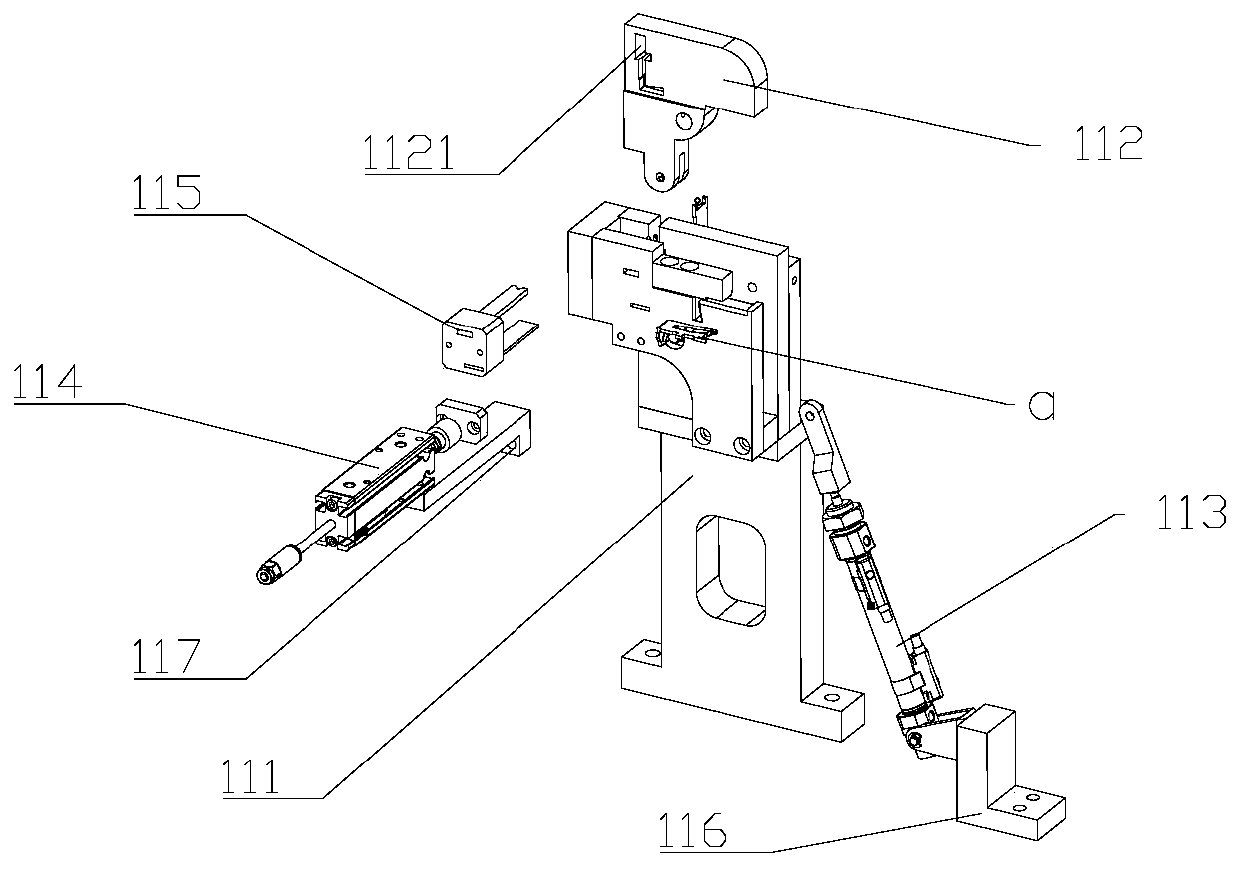

[0030] The shrapnel feeding device 1 is used to realize the feeding of the shrapnel, the shrapnel feeding device 1 is connected with the jig conveying device 3 through the first handling manipulator device 2, and the first handling manipulator device 2 is used to transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com