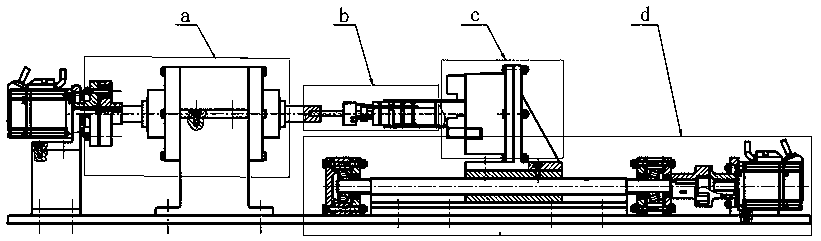

Magnetic grinding tool finishing processing device and method with adjustable magnetic field and self-adaptive aperture

A magnetic grinding tool and finishing technology, which is applied in the direction of grinding drive device, grinding workpiece support, metal processing equipment, etc., can solve the problems of non-adjustable magnetic field strength, large device structure, high heat generation, etc. The effect of increasing complexity, simplifying the process, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

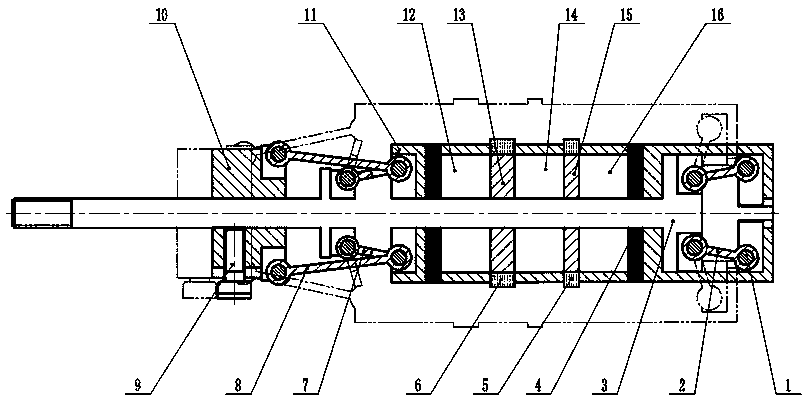

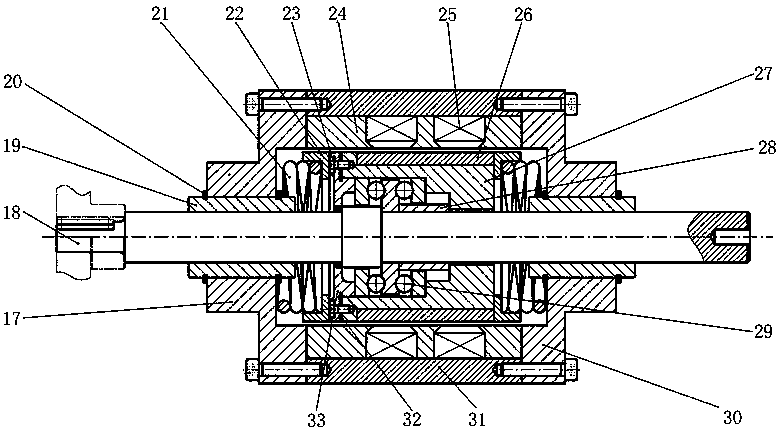

Method used

Image

Examples

Embodiment 1

[0049] A magnetic abrasive tool finishing device and method with an adjustable magnetic field and an adaptive aperture, the processing parameters of which are as described in Table 1:

[0050] Table 1 Example 1 Processing parameters

[0051] parameter

Magnetic pole speed /

(r / min)

SiC particles

Spend / #

Fe:

SiC

Workpiece material

quality

Inside the workpiece

Diameter / mm

The original roughness of the inner surface of the workpiece

Degree Ra / μm

Processing time /

min

value

300

240

13:7

6061 aluminum

33

0.772

15

[0052] Its specific steps:

[0053] 1. Adsorb the magnetic abrasive on the periphery of the soft iron.

[0054] 2. Clamp the tubular part to be processed on the three-jaw chuck, and then extend the finishing processing execution part into the interior of the tubular part.

[0055] 3. Start the motor and adjust its speed at 300r / min.

[0056] 4. After the rotation...

Embodiment 2

[0060] An adjustable magnetic field and self-adaptive aperture magnetic grinding tool finishing processing device and method, the processing parameters are as described in Table 2:

[0061] Table 2 Example 1 processing parameters

[0062] parameter

Magnetic pole speed /

(r / min)

abrasive grain

Spend / #

Fe:

SiC

Workpiece material

quality

Inside the workpiece

Diameter / mm

The original roughness of the inner surface of the workpiece

Degree Ra / μm

Processing time /

min

value

250

240

7:3

6061 aluminum

33

0.769

10

[0063] Its specific steps:

[0064] 1. Adsorb the magnetic abrasive on the periphery of the soft iron.

[0065] 2. Clamp the tubular part to be processed on the three-jaw chuck, and then extend the finishing processing execution part into the interior of the tubular part.

[0066] 3. Start the motor and adjust its speed at 250r / min.

[0067] 4. After the rotation sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com