Full-automatic pointer thermoprinting machine

A fully automatic, hot stamping machine technology, used in printing presses, rotary printing machines, general parts of printing machinery, etc., can solve the problems of hot stamping of automobile instrument pointers, poor hot stamping effect, poor product consistency, etc. Productivity, labor and production cost savings, reduced job site effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

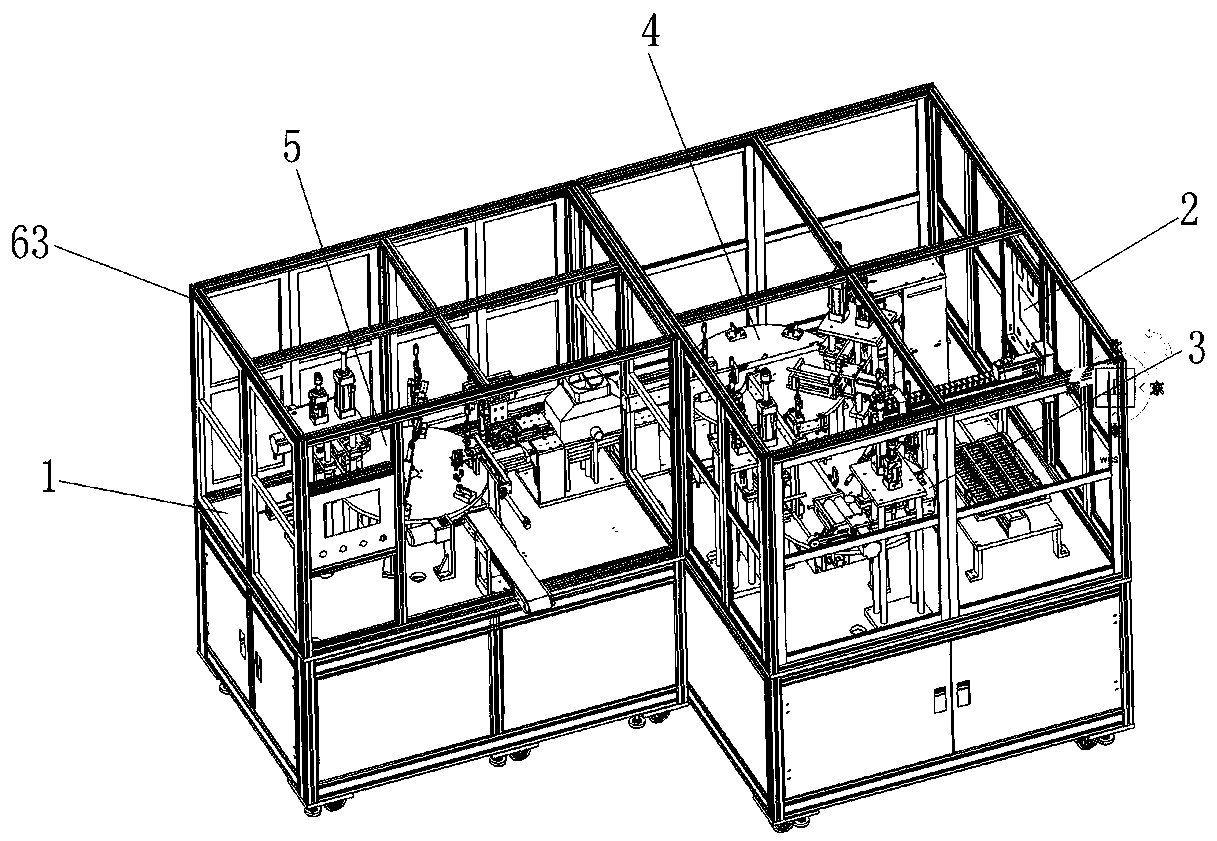

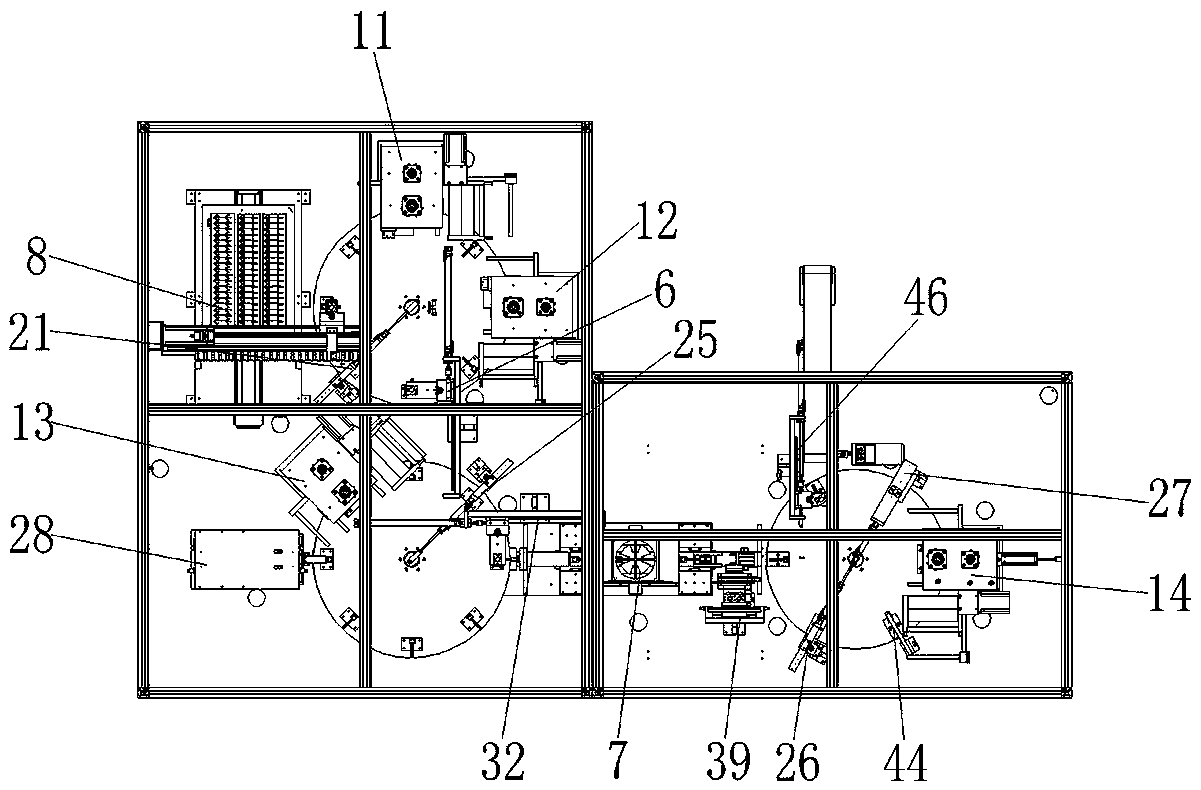

[0043] refer to figure 1 , figure 2 , a fully automatic pointer hot stamping machine, including a workbench 1 and a control device 2 for controlling the fully automatic pointer assembly machine, the workbench 1 is sequentially provided with a first eight-station turntable 3, a second eighth station Turntable 4, a six-station turntable 5, a first transfer mechanism 6 is provided between the first eight-station turntable 3 and the second eight-station turntable 4, the six-station turntable 5 and the second There is a drying mechanism 7 between the eight-station turntable 4;

[0044] The first eight-station turntable 3 is provided with eight pointer body station fixtures, which are successively divided into pointer body feeding station, idle stroke station, first heat transfer station, idle stroke station, second Second thermal trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com