Central air conditioner heat energy recycling device and method

A heat recovery and central air-conditioning technology, which is applied in energy recovery systems for ventilation and heating, heating methods, air-conditioning systems, etc., can solve problems affecting indoor air quality, inconvenience, etc., to reduce labor intensity, increase costs, and reduce placement Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

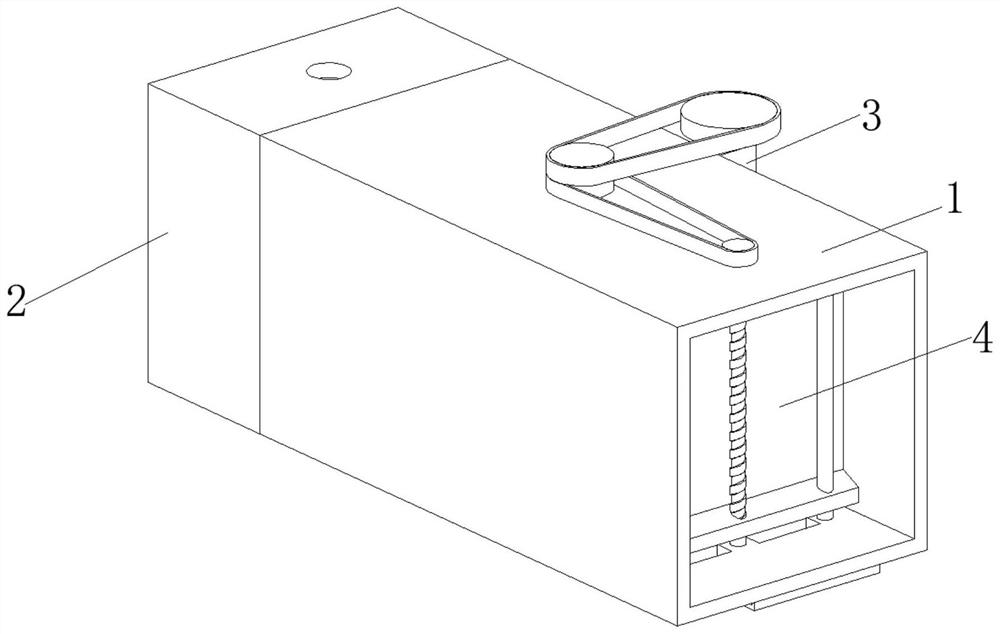

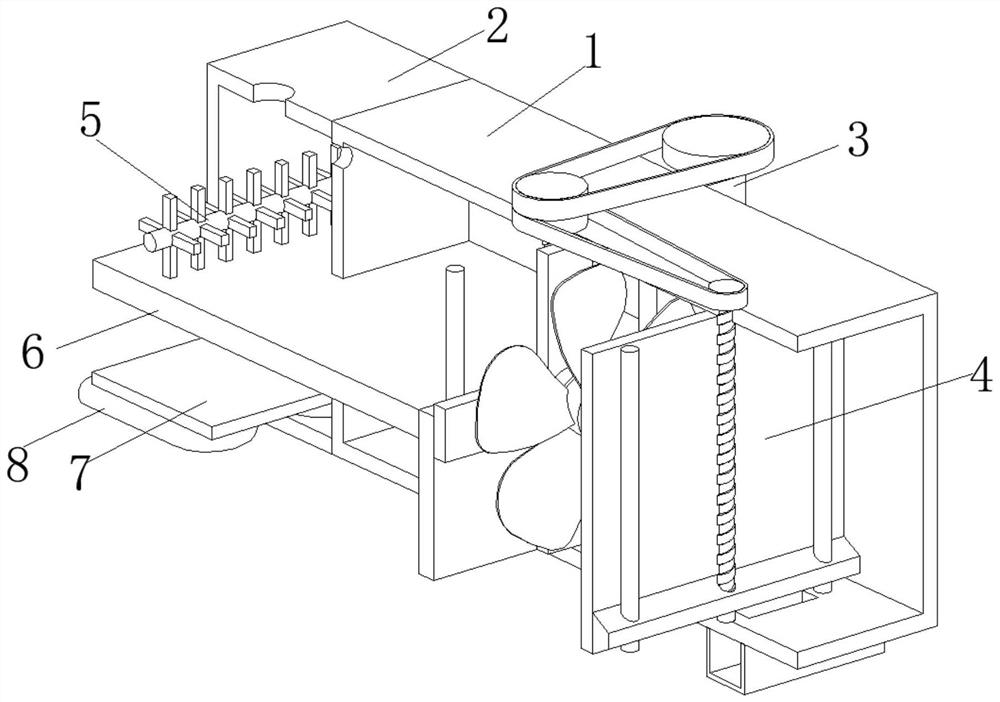

[0038] A central air-conditioning heat recovery device and method, such as Figure 1-Figure 7 As shown, the box body 1 is included, the left side of the box body 1 is welded with an auxiliary box 2, the rear portion of the box body 1 is provided with a transmission mechanism 3, the inside of the box body 1 is provided with a cleaning mechanism 4, and the inside of the auxiliary box 2 is provided with a The processing mechanism 5, the inner wall of the box body 1 and the auxiliary box 2 are welded with a partition plate 6, the inner wall of the auxiliary box 2 is welded with a splint 7, and the left side of the box body 1 is communicated with a ventilation pipe 8.

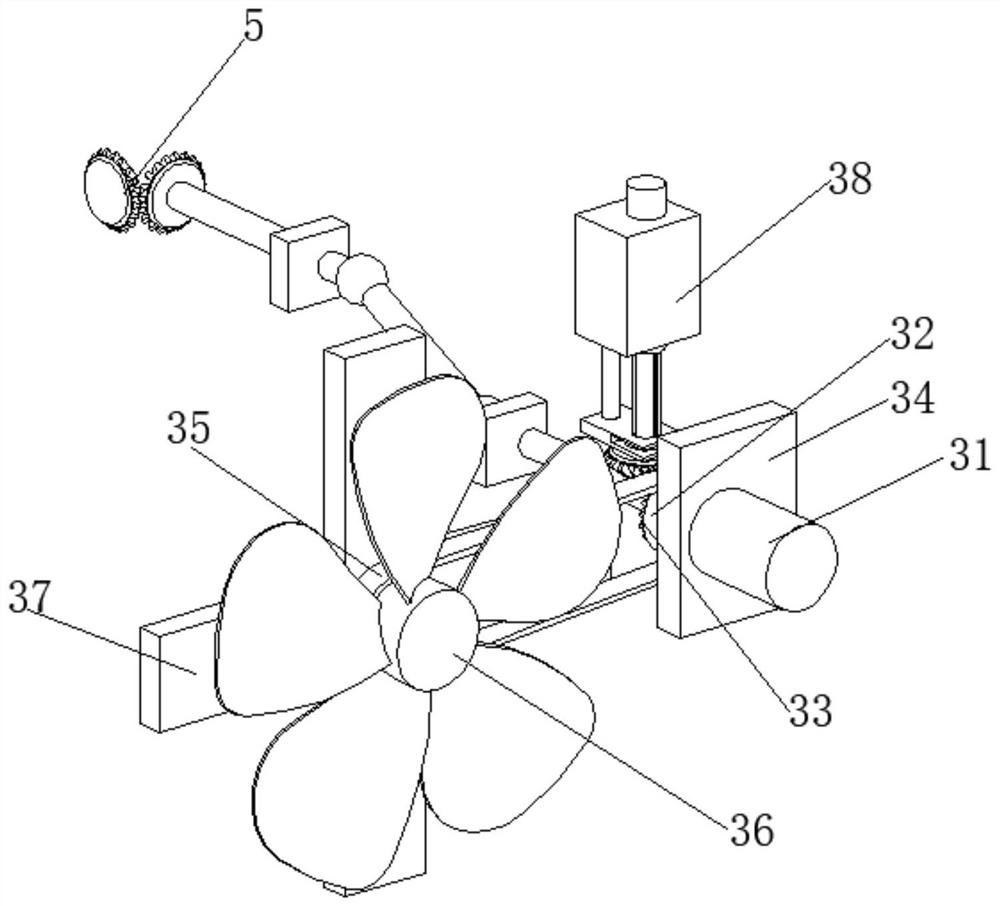

[0039]In this embodiment, the transmission mechanism 3 includes a motor 31, the output end of the motor 31 is welded with a No. 1 pulley 32, and the shaft center of the No. 1 pulley 32 is welded with a No. 1 bevel gear 33, and the left end of the motor 31 is connected with a support plate 34 by bolts. , the surface ...

Embodiment 2

[0045] like Figure 4-Figure 7 As shown, the axis of the large belt pulley 41 is welded and fixed to the top of the telescopic column 382, the surfaces of the No. 1 screw 44 and the No. 2 screw 45 are connected with the inner wall of the box body 1 in rotation, and the baffle plate 47 is located between the partition plate 6 and the support bar. Between 37, the surfaces of the baffle plate 47 and the scraper 49 are slidingly connected with the inner wall of the box body 1, and the left side of the scraper 49 is in contact with the right side of the filter plate 48.

[0046] It is worth noting that the processing mechanism 5 includes a fixed plate 51, the inner wall of the fixed plate 51 is rotatably connected with a transmission rod 52, the left end of the transmission rod 52 is welded with a No. 3 bevel gear 53, and the surface of the No. 3 bevel gear 53 is engaged with a No. 4 cone Gear 54, No. 4 bevel gear 54 is welded with rotating shaft 55 at the axial center, the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com