Lead-free ferroelectric upconversion luminescent material and preparation method thereof

A luminescent material and ferroelectric technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unable to meet the temperature measurement requirements, and the measurement environment has a large impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

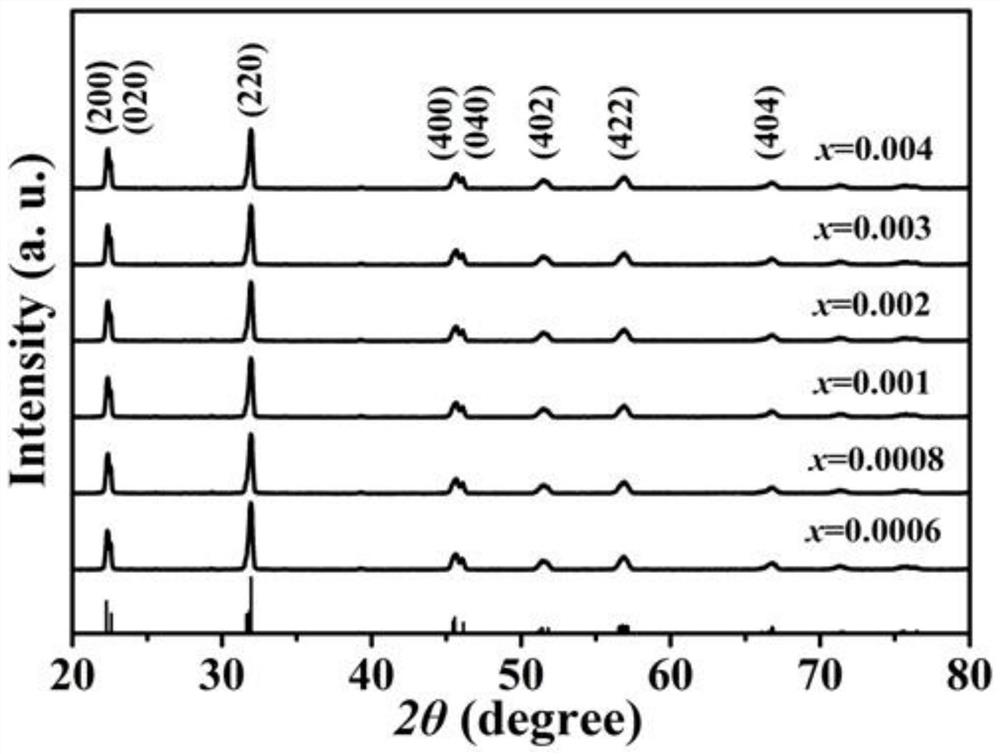

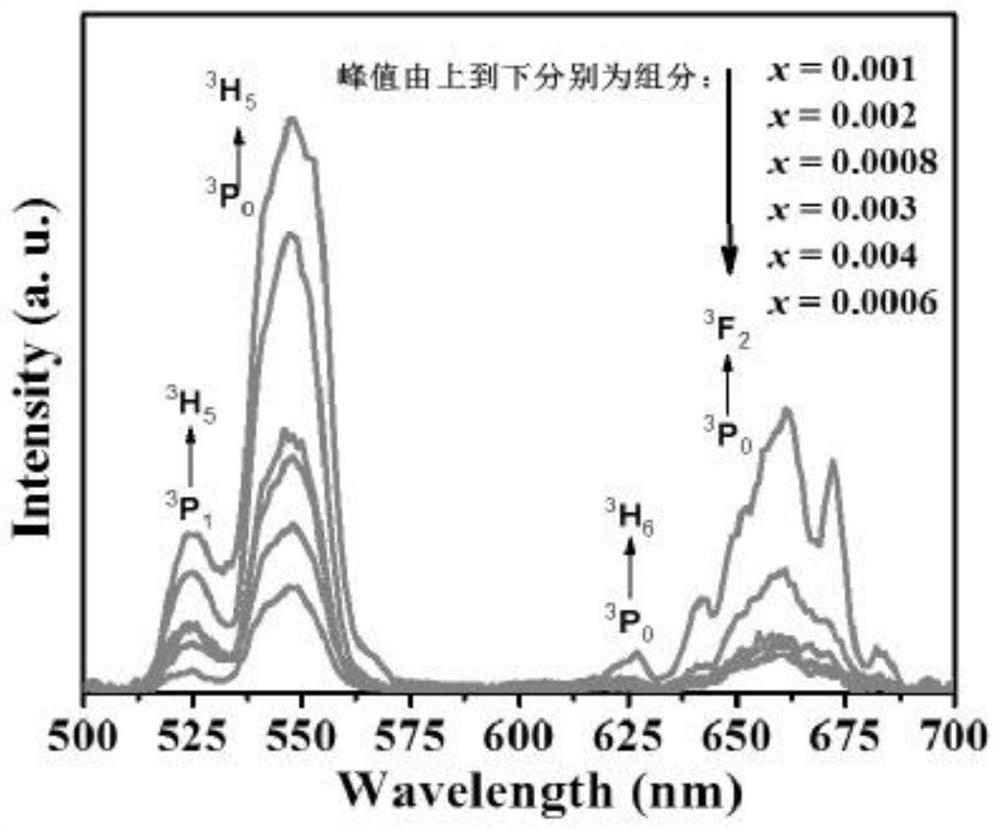

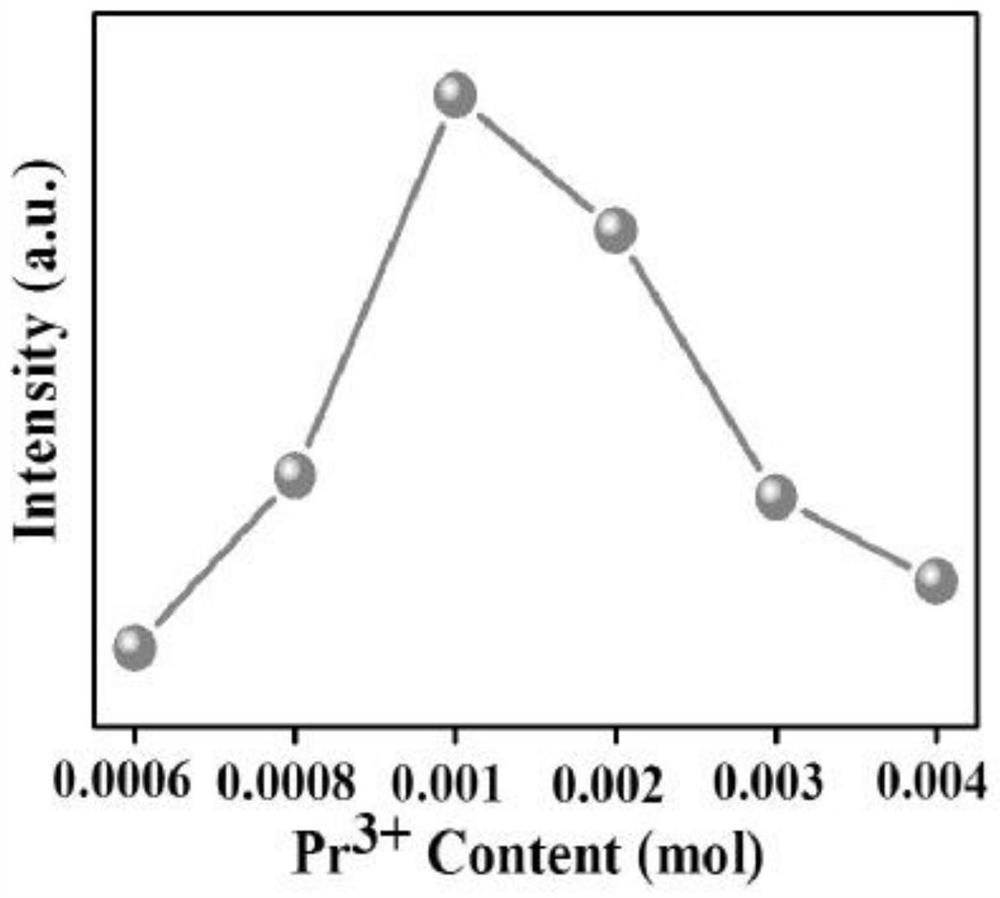

[0036] Using high-purity K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , Pr 2 o 3 and Yb 2 o 3 As raw material, according to (Na 0.5 K 0.5 ) 1-x-0.01 NbO 3 : x PR 3+ / 0.01Yb 3+ ( x =0.0006, 0.0008, 0.001, 0.002, 0.003, 0.004) in K, Na, Nb, Pr and Yb stoichiometric ratio to weigh the ingredients, then put the raw materials into the ball mill jar for ball milling, the ball milling conditions are: agate ball milling beads The number ratio of medium and large grains to small grains is 1:3, and the volume ratio of raw material volume to absolute ethanol is 1: 1.5; after ball milling for 9 hours, the raw materials are put into an oven for drying, and after drying, the raw materials are sieved once, and then Tablets were pressed by a tablet machine at 200 MPa, and the large tablets were placed in a muffle furnace at 850 °C for 4 hours to synthesize (Na 0.5 K 0.5 ) 1-x-0.01 NbO 3 : x PR 3+ / 0.01Yb 3+ Sample precursors. The obtained sample precursor was crushed again, put in...

Embodiment 2

[0042] Using high-purity K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , Pr 2 o 3 and Yb 2 o 3 As raw material, according to (Na 0.5 K 0.5 ) 1-x-0.01 NbO 3 : x PR 3+ / 0.01Yb 3+ ( x =0.002) in K, Na, Nb, Pr and Yb stoichiometric ratio carry out weighing batching, then raw material is put into ball mill jar and carry out ball milling, and ball milling condition is: the number ratio of large particle and small particle in the agate ball milling bead is 1 : 3.5, the volume ratio of raw material volume and dehydrated ethanol is 1: 2.5; After ball milling 8 hours, raw material is put into baking oven and dries, and after drying, raw material is sieved once, utilizes tablet press to compress tablet under 150 MPa After the pressing, the large sheet was put into a muffle furnace and kept at 800°C for 8 hours to synthesize a perovskite structure (Na 0.5 K 0.5 ) 1-x-0.01 NbO 3 : x PR 3+ / 0.01Yb 3+ Sample precursors. The obtained sample precursor was crushed again, put into the...

Embodiment 3

[0047] Using high-purity K 2 CO 3 , Na 2 CO 3 , Nb 2 o 5 , Pr 2 o 3 and Yb 2 o 3 As raw material, according to (Na 0.5 K 0.5 ) 1-x-0.01 NbO 3 : x PR 3+ / 0.01Yb 3+ ( x =0.004) in K, Na, Nb, Pr and Yb stoichiometric ratio carry out weighing batching, then raw material is put into ball mill jar and carry out ball milling, and ball milling condition is: the number ratio of large particle and small particle in the agate ball milling bead is 1 : 3.2, the volume ratio of raw material volume and dehydrated ethanol is 1: 2; After ball milling for 10 hours, raw material is put into oven for drying, and after drying, raw material is sieved once, and utilizes tabletting machine to compress tablet under 220 MPa After the pressing, the large sheet was put into a muffle furnace and kept at 820°C for 6 hours to synthesize a perovskite structure (Na 0.5 K 0.5 ) 1-x-0.01 NbO 3 : x PR 3+ / 0.01Yb 3+ Sample precursors. The obtained sample precursor was crushed again, put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com