Electrochemical surface inclusion removing based super corrosion resistance treatment method of stainless steel

A treatment method and technology for inclusions, applied in the field of removal of inclusions on the surface of stainless steel and improvement of corrosion resistance of passivation film, electrochemical treatment, can solve the problem that the corrosion resistance of stainless steel cannot meet the corrosion resistance requirements of high-temperature, high-salinity harsh environments, etc. problem, to achieve the effect of simple passivation solution and electrochemical passivation method, increase the content of chromium oxide, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

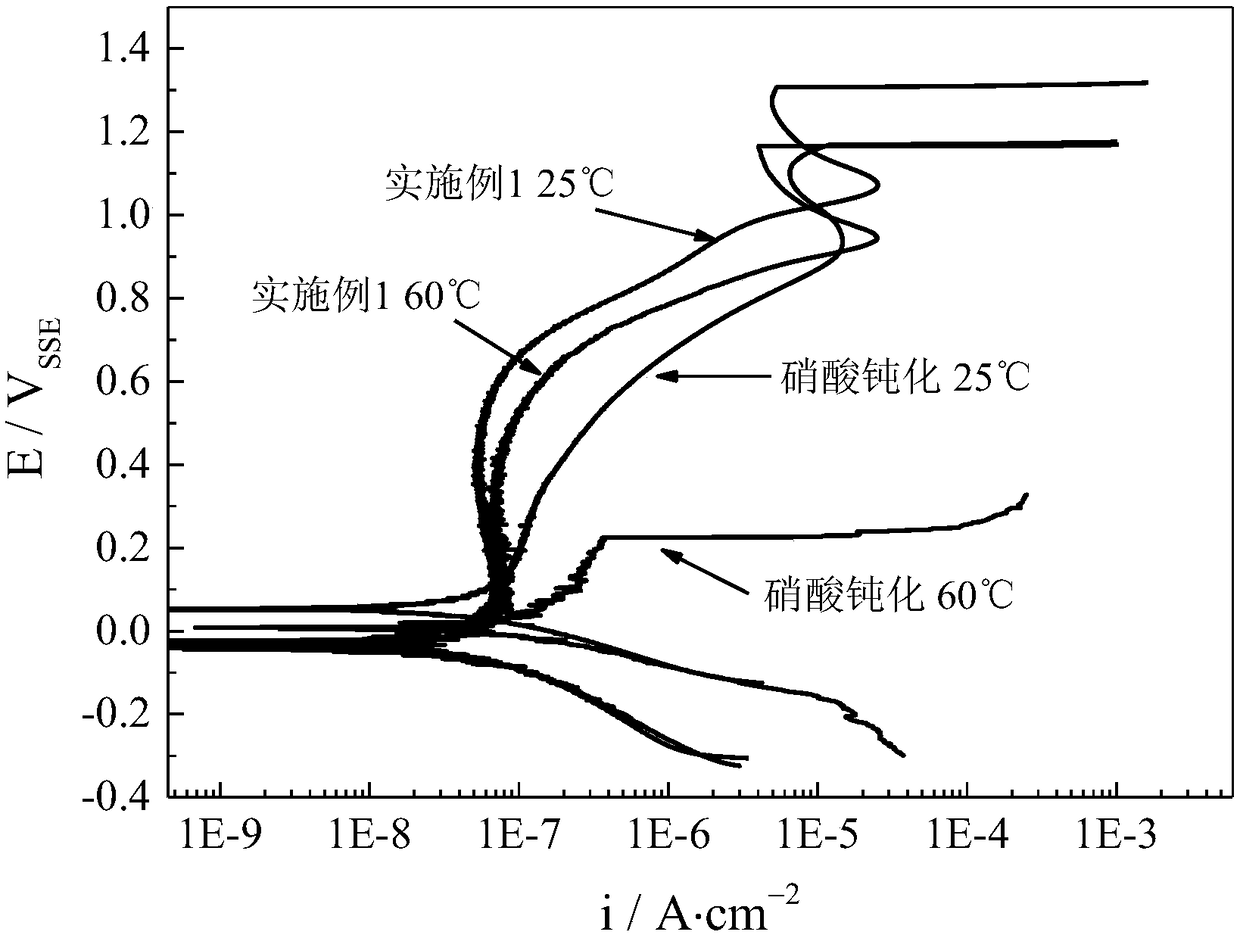

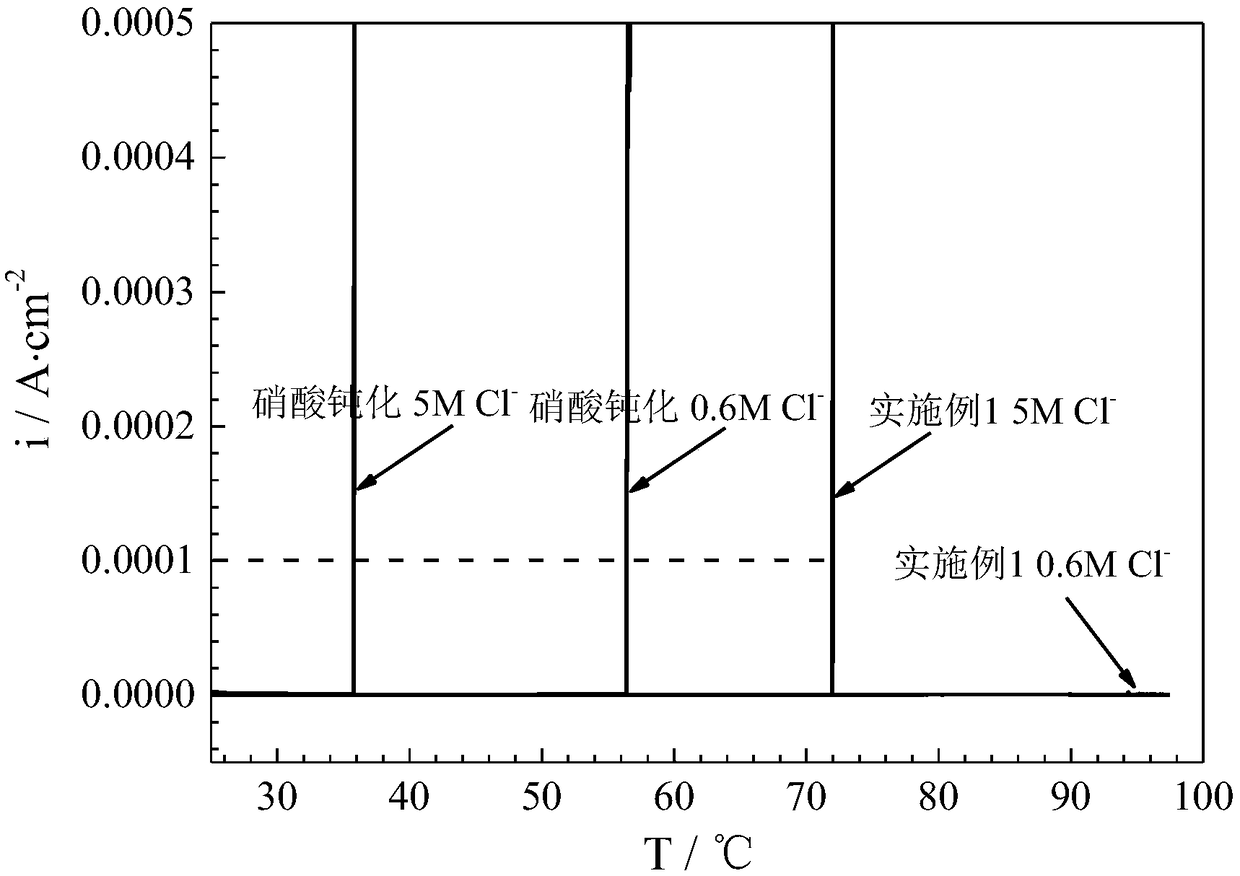

[0021] Example 1 Multi-period potential step control method to remove inclusions

[0022] The solution used in the inventive method is: the mass percentage is the NaNO of 20% nitric acid, 5mol / L 3 Solution, the water used to configure the solution is deionized water, the mass percentage concentration of the chemical reagent nitric acid used is 68%, NaNO 3 For analytically pure reagents.

[0023] Use the different passivation treatment steps in the above-mentioned embodiment 1 as follows:

[0024] (1) Put the sample into 20% nitric acid solution at 50°C for passivation for 0.5h and then clean it;

[0025] (2) Put the cleaned sample in 5mol / L NaNO at 50°C 3 Multi-cycle potential step treatment is carried out in the solution, and the counter electrode is made of duplex stainless steel. The single-cycle electrochemical treatment includes the following three stages: first, the anode step potential is changed from 0.5V to SSE Linearly polarized to 0.8V SSE , the processing time...

Embodiment 2

[0028] Example 2 Multi-period potential step control method to remove inclusions

[0029] The solution used in the inventive method is: the nitric acid solution that the mass percent is 20%, the NaNO that concentration is 5mol / L 3 Solution, the water used to configure the solution is deionized water, the mass percentage concentration of the chemical reagent nitric acid used is 68%, NaNO 3 For analytically pure reagents.

[0030] Use different passivation treatment steps in the above-mentioned embodiment 2 as follows:

[0031] (1) Passivate a part of the sample in 50°C, 20% nitric acid solution for 0.5h, and ultrasonically clean it with deionized water;

[0032] (2) Put the sample in 5mol / L NaNO at 40°C 3 After 300 cycles of potential step treatment in the solution: a titanium plate is used for the counter electrode, and the anode step potential is from 0.5V SSE to 0.8V SSE , the processing time is 17s, the cathode potential is -0.5V SSE , the processing time is 5s, and f...

Embodiment 3

[0034] Example 3 Multi-period potential step control method to remove inclusions

[0035] A stainless steel super corrosion-resistant treatment method based on electrochemical removal of surface inclusions, comprising the following steps:

[0036](1) After degreasing and cleaning the surface of the stainless steel object to be treated, it is placed in a 50°C, 5wt.% sulfuric acid solution for passivation treatment to obtain a pretreated surface.

[0037] (2) Remove the inclusions on the pretreatment surface to thicken the passivation film and improve the protection of the passivation film

[0038] Put the sample in 10mol / L NaNO at 60℃ 3 After 20 cycles of potential step treatment in the solution: graphite is used as the counter electrode, and the anode step potential is from 0.5V SSE to 0.8V SSE , the processing time is 20.5s, the cathode potential is -0.1V SSE , the processing time is 7.5s, and finally step to the initial potential of 0.5V SSE , keep 2s, single cycle time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com