Construction method of underwater large-depth open caisson penetrating through hard and difficult-to-break soil layer

A construction method and a large-depth technology, applied in caisson, infrastructure engineering, construction, etc., can solve the problems of difficult operation of grab buckets, reduced soil extraction speed, soil grabbing, etc., to improve soil extraction efficiency and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

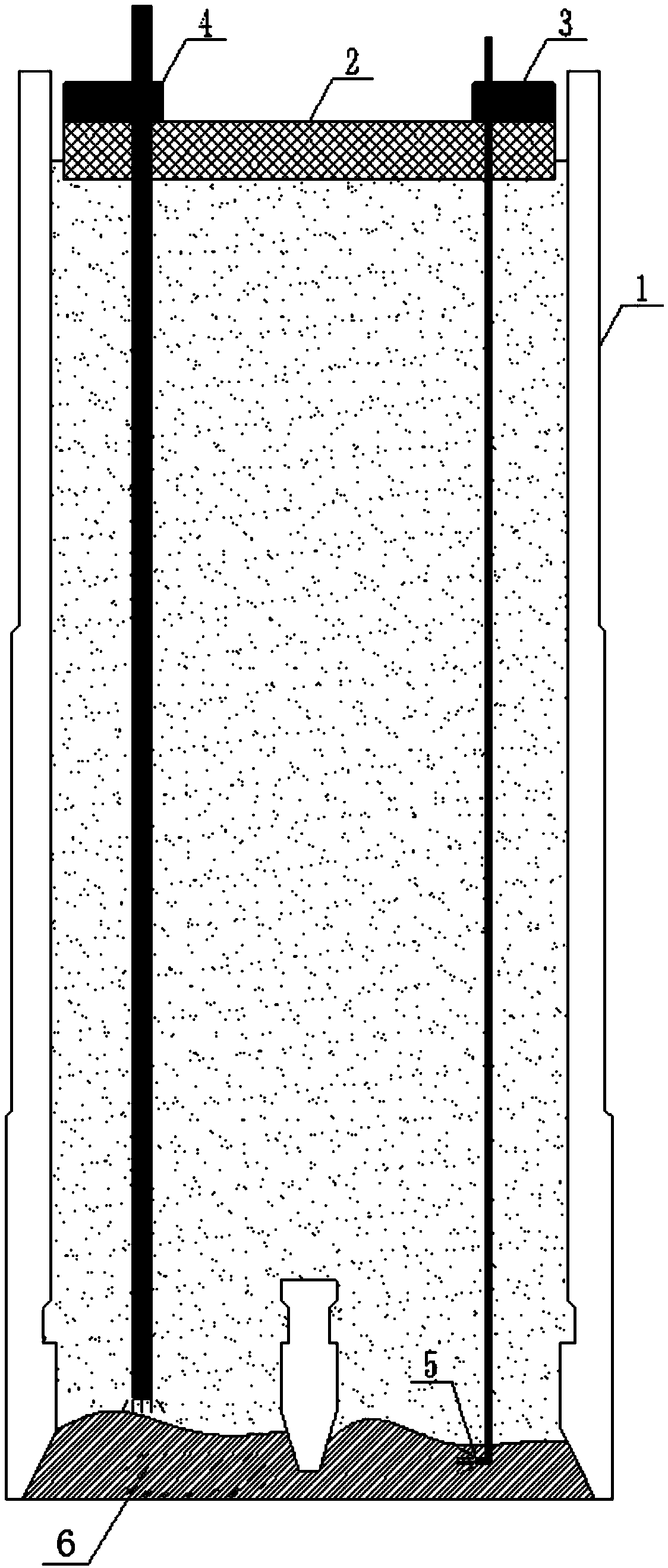

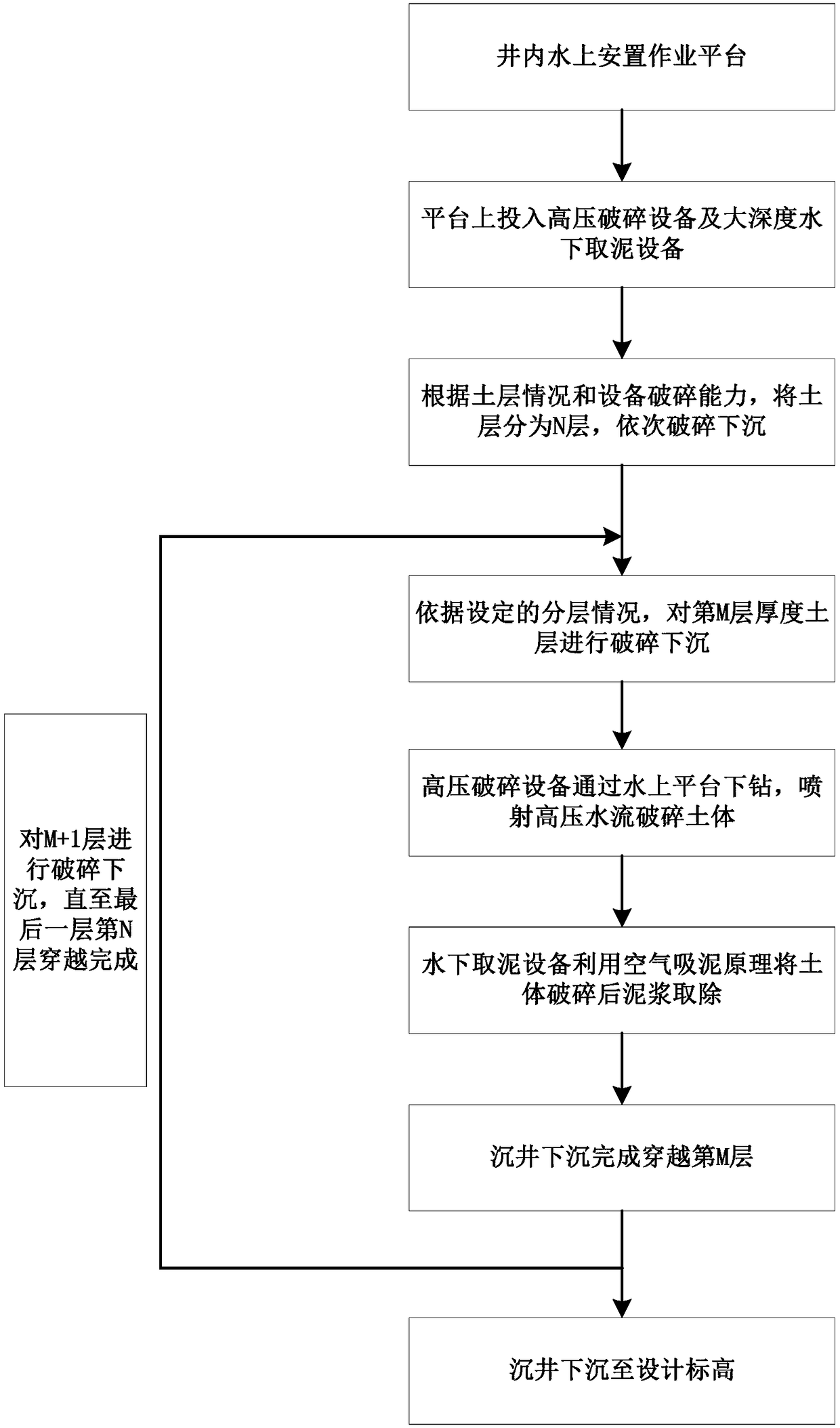

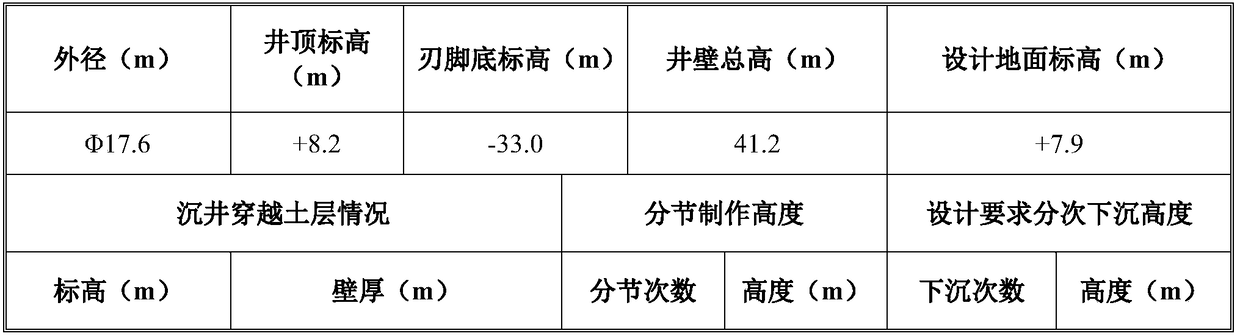

[0047] Such as figure 1 As shown, the construction method for underwater large-depth caissons passing through hard and difficult-to-break soil layers of the present invention uses the above-water operation platform 2, high-pressure crushing equipment 3 and underwater mud extraction equipment 4 to complete the caisson 1 passing through hard and difficult-to-break soil layers. For the operation of the soil layer, the caisson 1 adopts the non-drainage process, the water level in the caisson chamber is equal to the outside groundwater level, the water working platform 2 is placed on the water surface in the caisson, and the high-pressure crushing equipment 3 and the underwater mud extraction equipment 4 are placed on the water On the working platform 2, use the self-rotating ability of the working platform 2 and the working tank to crush and abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com