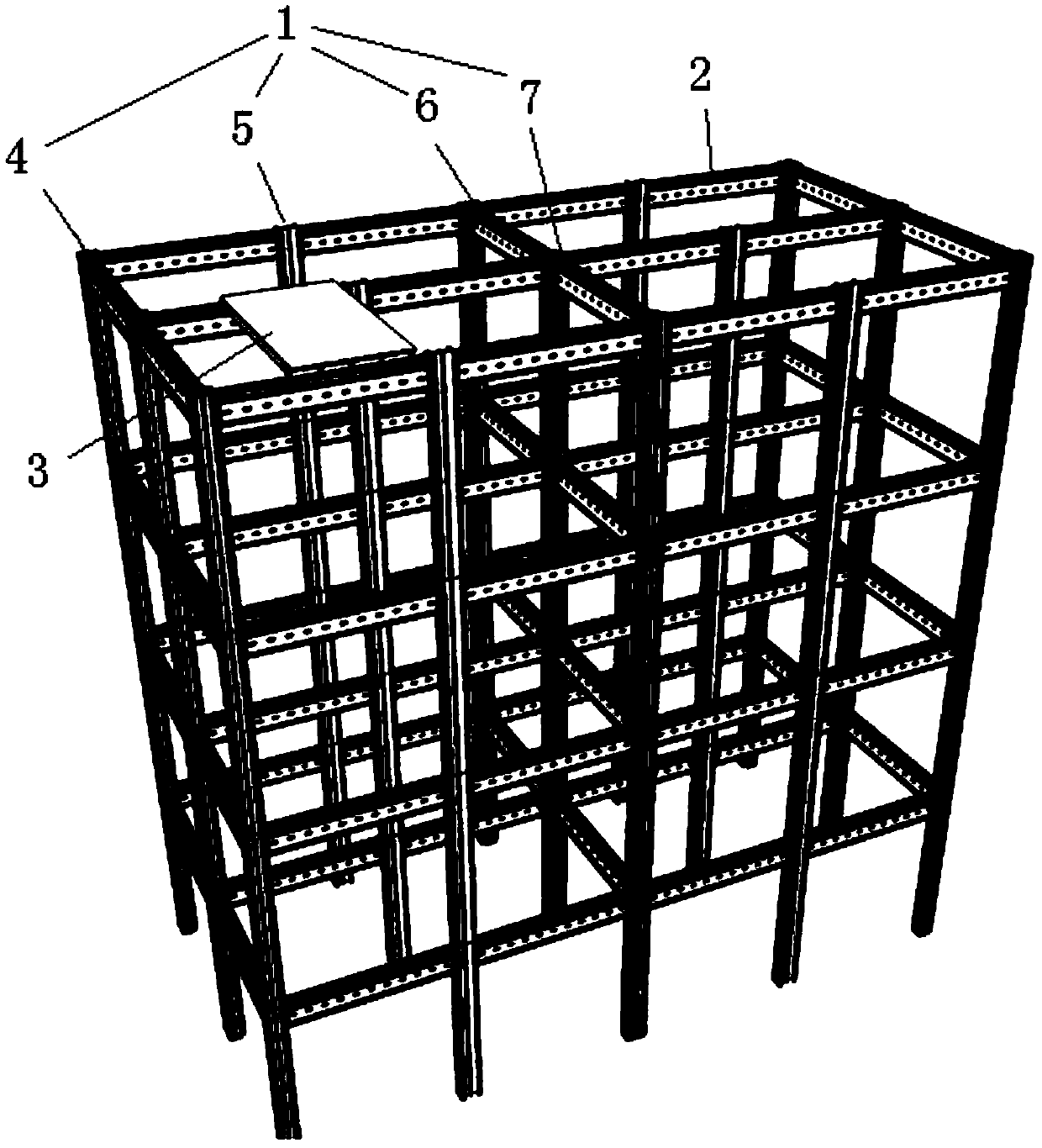

Structural system and construction method of prefabricated cold-formed thin-walled steel composite house

A technology of cold-formed thin-walled steel and thin-walled steel, which is applied in building construction, building material processing, construction, etc., can solve the problems of poor structural stability and low bearing capacity, achieve high bearing capacity, improve rigidity and strength , the effect of high resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

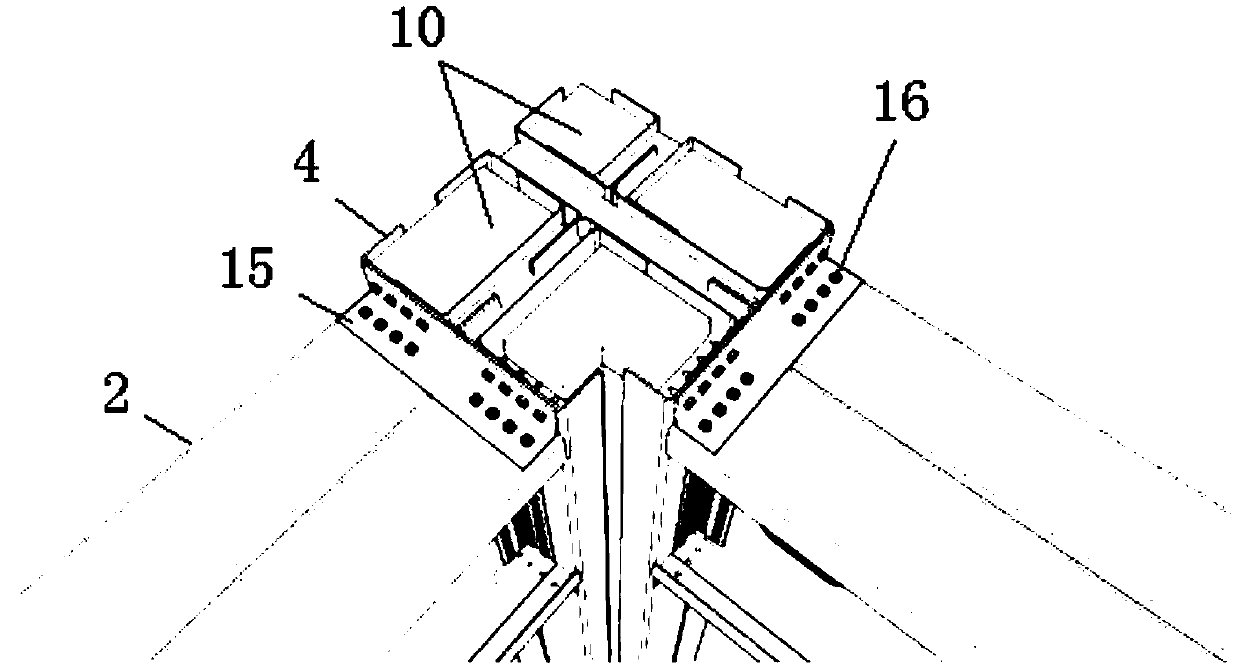

[0055] see Figure 7 As a specific embodiment of the prefabricated cold-formed thin-walled steel composite house structure system provided by the present invention, the I-shaped side column 5 includes three first assemblies and two fourth assemblies with back-to-back gaps. The fourth assembly is vertically connected to one of the first assemblies, parallel to the other two first assemblies, and two parallel U Shaped thin-walled steel. Similarly, the cavity formed after the U-shaped thin-walled steels are stacked is filled with the foam-type thermal insulation material used for thermal insulation.

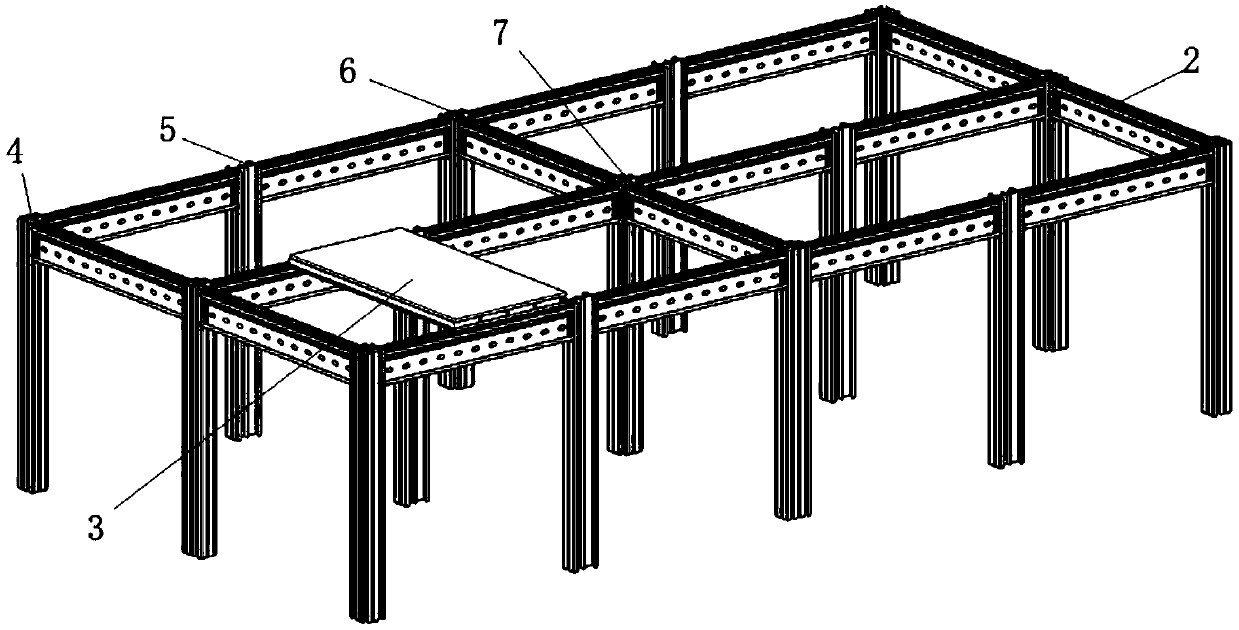

[0056] see Figure 5 , as a specific embodiment of the prefabricated cold-formed thin-walled steel composite house structure system provided by the present invention, the center column 7 includes four first assemblies, and the four first assemblies enclose the center column 7 with a rectangular section , the fifth assembly is connected between one set of the first assembly, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com