Coiled tubing four-flashboard blowout preventer suspended radial-shrinkage automatic compensation device and method

A technology of automatic compensation and blowout preventer, which is applied in the direction of drill pipe, casing, earthwork drilling and production, etc. It can solve the problems affecting the inner diameter of coiled tubing, micro-deformation, shedding, etc., to achieve better clamping effect and increase contact area, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

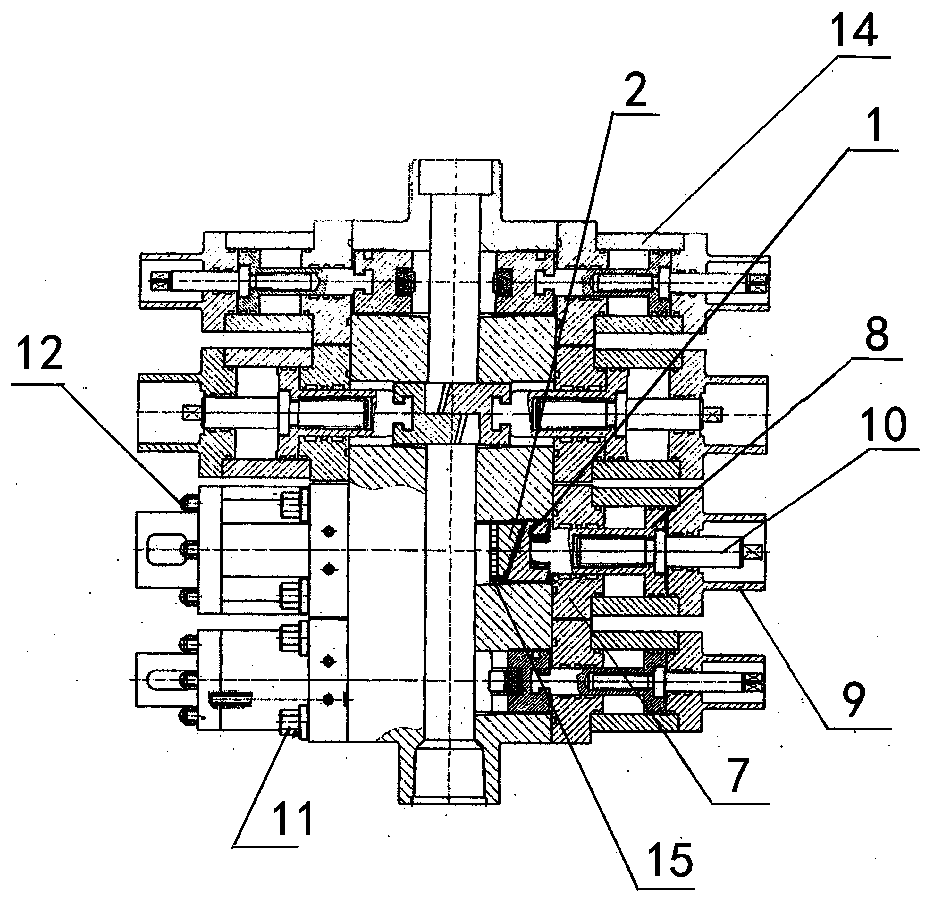

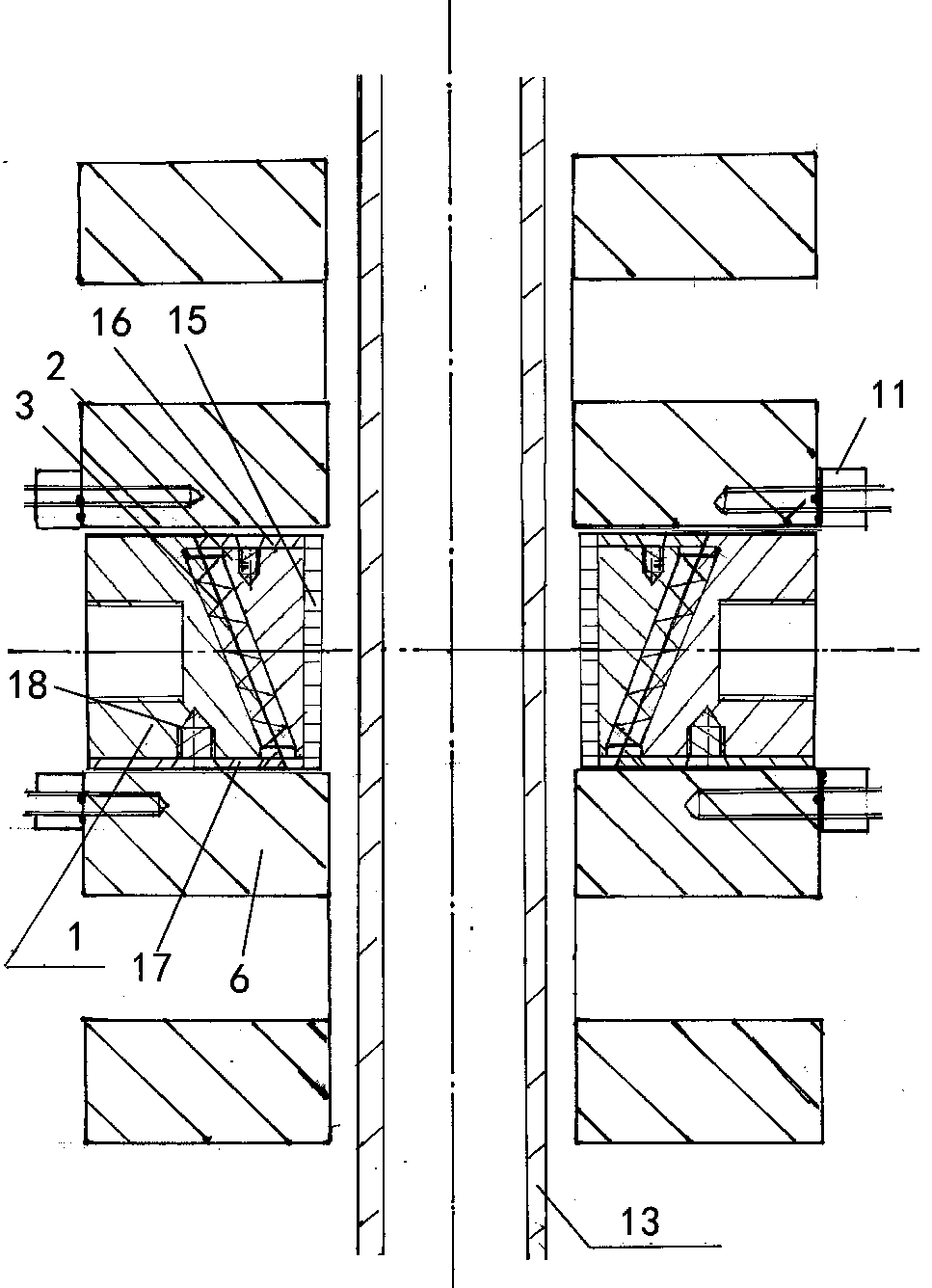

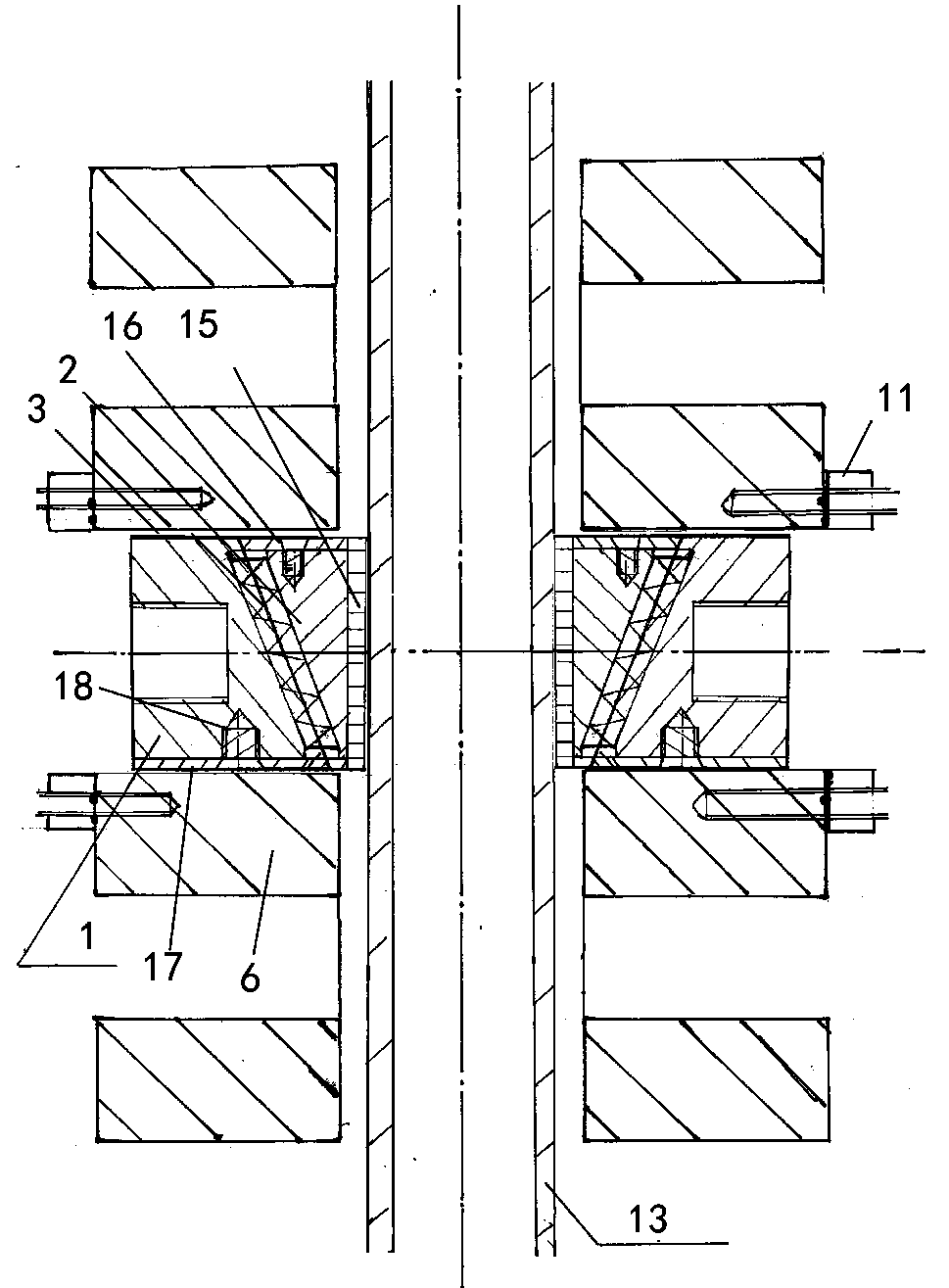

[0033] Embodiment 1, with reference to attached figure 1, a coiled tubing four-ram blowout preventer hanging diameter automatic compensation device mentioned in the present invention, its technical solution is: comprising a compensation fixed body 1, a compensation movable body 2, a support spring 3, slips 15, the described The outer side of the compensating fixed body 1 is connected with the moving piston 8, and the two sets of compensating fixed bodies 1 form a trapezoidal body cavity structure, and cooperate with two groups of compensating movable bodies 2, and the height of the compensating movable body 2 is equal to the height of the compensating fixed body 1, each Slips 15 are installed on the inner side of the compensation movable body 2, and the outer wall of the coiled tubing 13 is fixed through the slips 15 to prevent the coiled tubing from falling off; There is a lower baffle 17; the outer slope of each compensation movable body 2 and the inner slope of the compensa...

Embodiment 2

[0045] Embodiment 2, with reference to attached Figure 8 , a coiled tubing four-ram blowout preventer hanging diameter automatic compensation device mentioned in the present invention is different from Embodiment 1 in that the slip teeth on the inner surface of the slips mentioned in the present invention adopt ring teeth, The cross-section of the ring teeth is a right triangle structure, so that the cylindrical slip surface formed by the combination of two sets of slips can be firmly fixed and hugged when in contact with the outer wall of the coiled tubing.

Embodiment 3

[0046] Embodiment 3, a coiled tubing four-ram blowout preventer hanging diameter automatic compensation device mentioned in the present invention, differs from Embodiments 1 and 2 in that the slip teeth on the slip inner surface mentioned in the present invention The adopted "well" shaped teeth have grooves distributed both horizontally and vertically. In this way, when the cylindrical slip surface formed by the combination of two sets of slips contacts the outer wall of the coiled tubing, the gripping force is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com