Method for detecting and correcting error in optical mirror machining caused by airflow

An optical mirror surface and error detection technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of low processing precision of optical mirror surfaces, and achieve the effects of improving reliability, improving ability, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings.

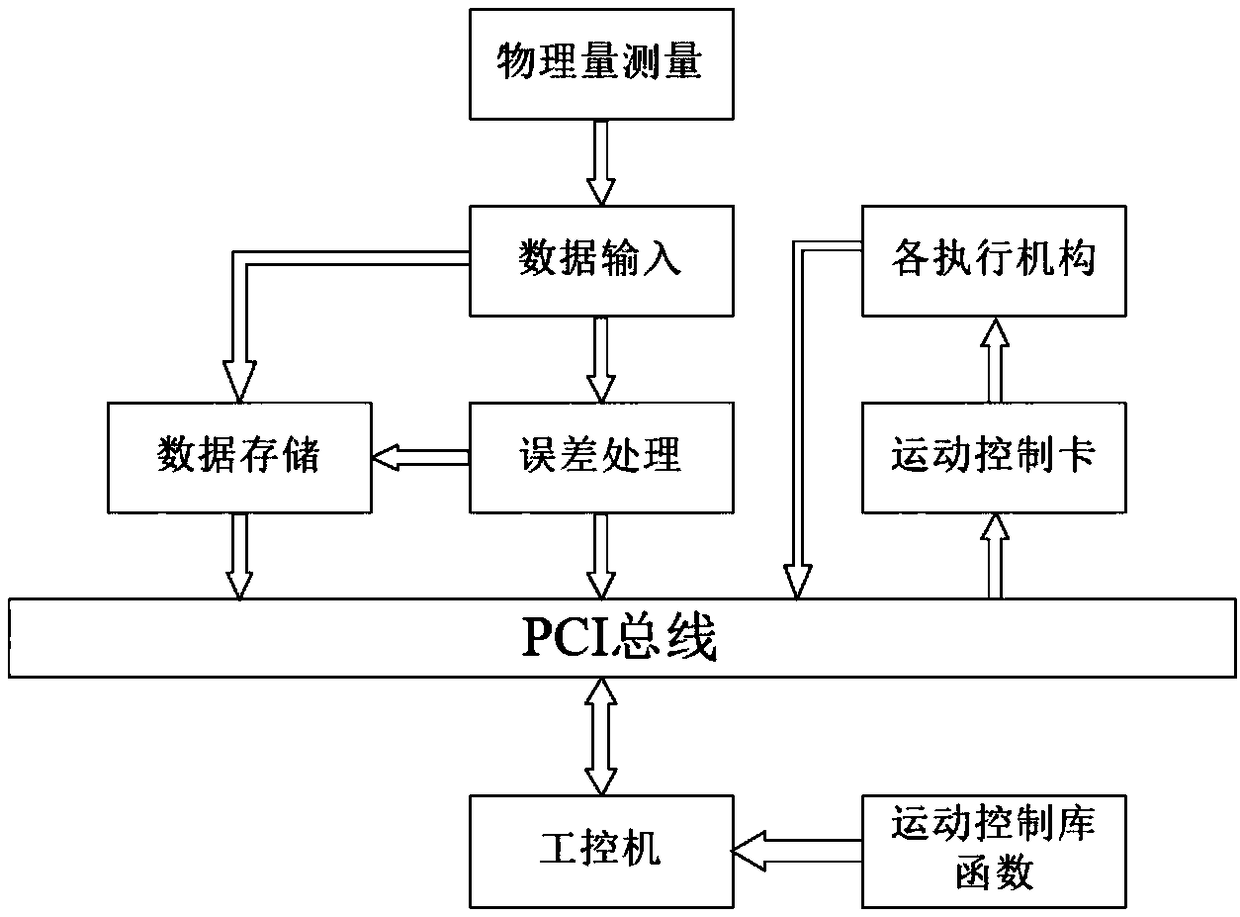

[0021] figure 1 Shown is a block diagram of the overall structure of an optical mirror processing detection error correction system caused by airflow, and its working process is as follows:

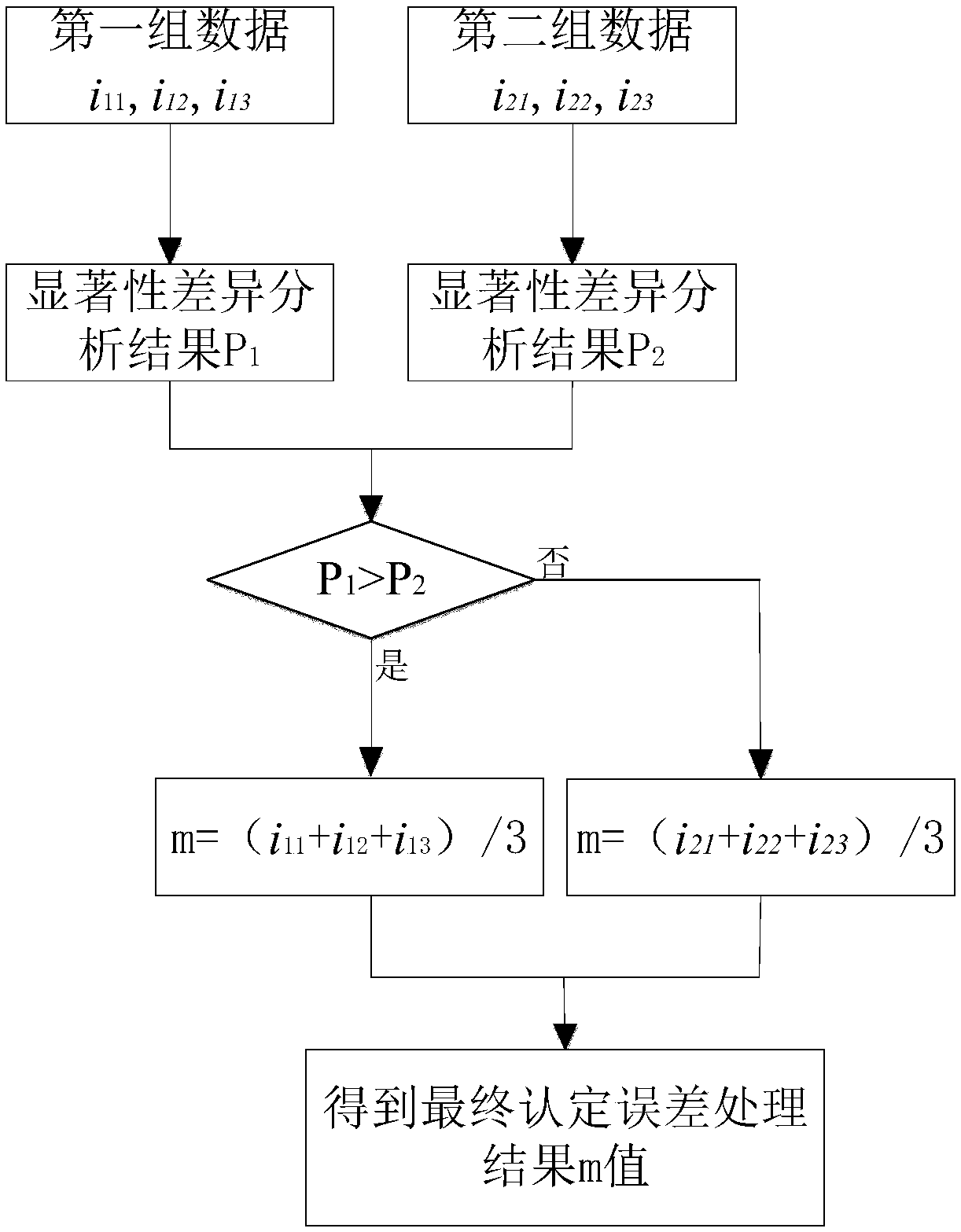

[0022] 1) The original optical mirror processing control system executes the processing process according to the set processing steps. After the processing of each step is completed, the optical mirror processing robot will suspend the processing action within a certain period of time. Physical quantity measurement, using an interferometer to measure the size of the current optical mirror, continuously measuring the readings 6 times, and dividing the measured values into two groups, namely i 11 , i 12 , i 13 , i 21 , i 22 , i 23 , while measuring the size of the optical mirror, use the airflow detection device to measure the airflow value on the surface of the optical mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com