Measuring machine for height of optical spacer

A measuring machine and gasket technology, which is applied in the direction of using optical devices, measuring devices, and using electric methods for temperature control, etc., can solve problems such as inaccurate measurement data, improve accuracy, improve liquid crystal display effects, and eliminate fluctuations effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

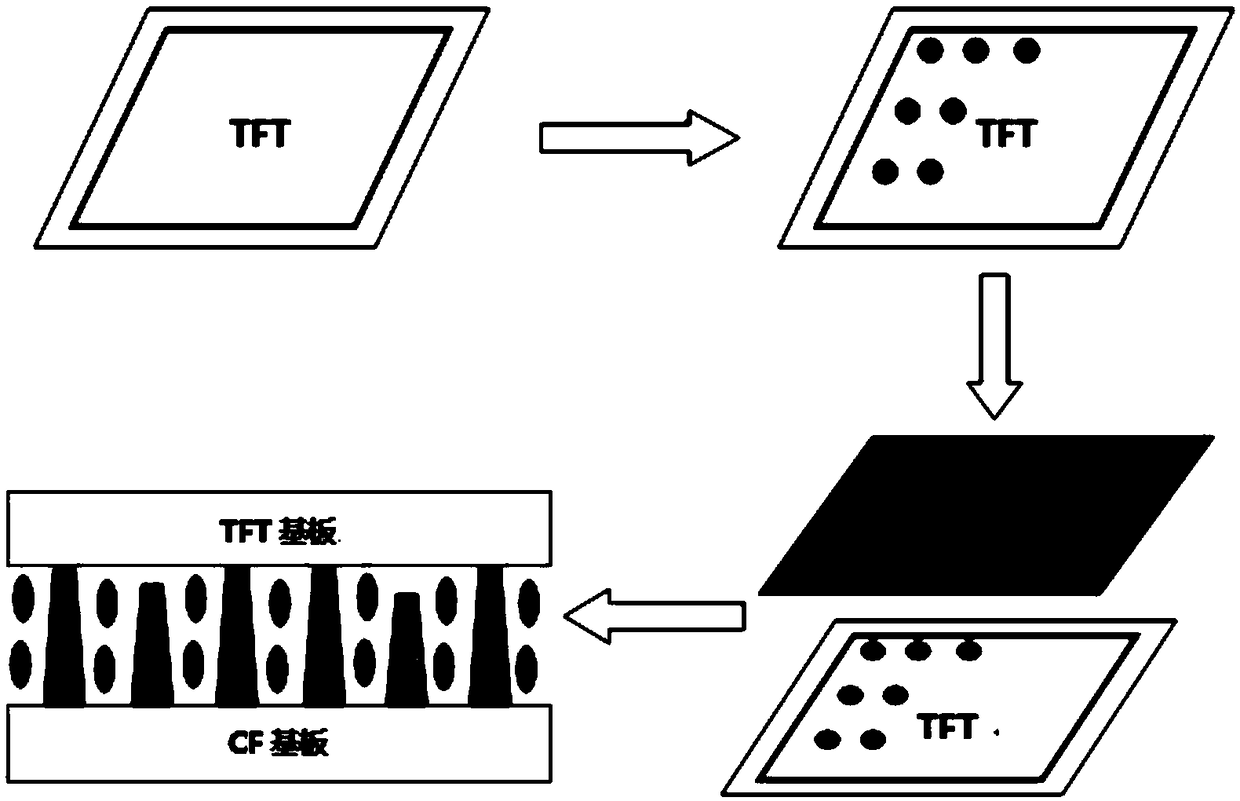

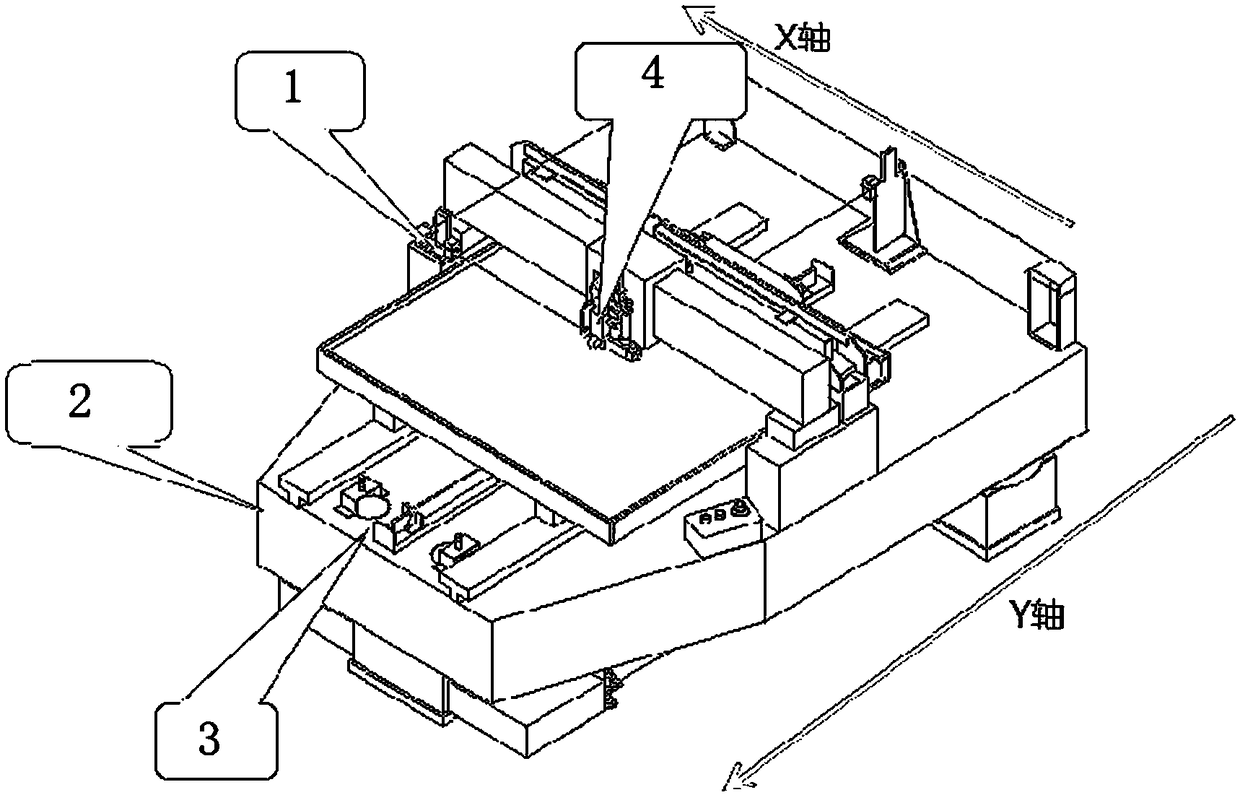

Method used

Image

Examples

Embodiment approach

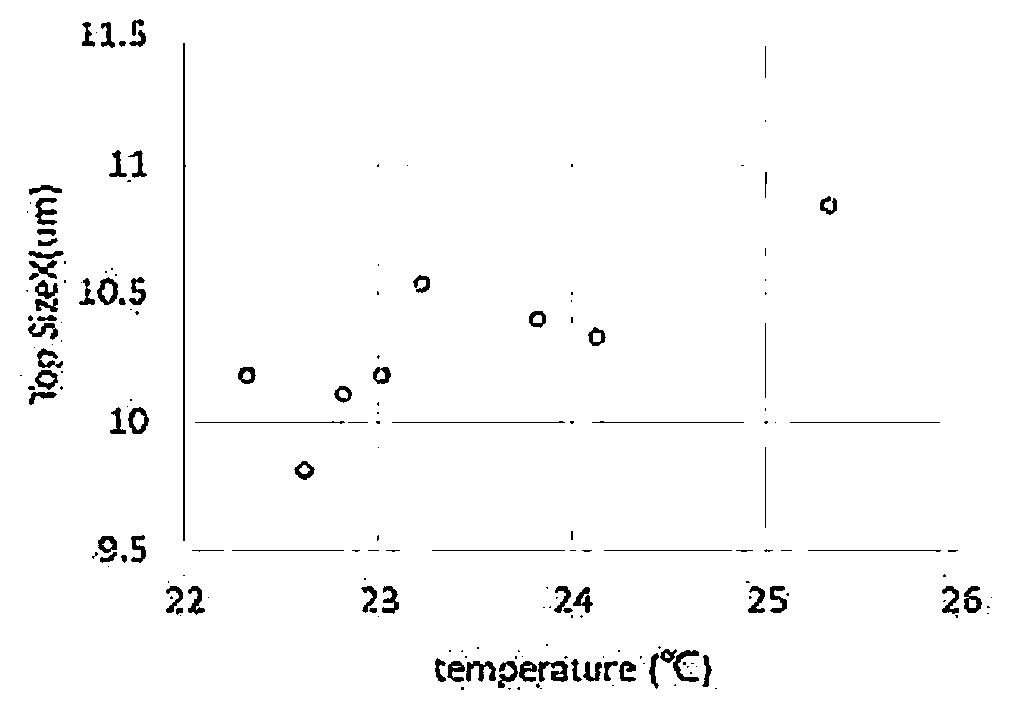

[0031] In the first type, there are two film-shaped constant-temperature liquid circulation pipelines 5, which are respectively attached to the two opposite sides of the base 2, and the two film-shaped constant-temperature liquid circulation pipelines 5 are connected in series or in parallel connected to the liquid supply system. Wherein, in this embodiment, the constant temperature effect of the parallel-connected thin-film constant-temperature liquid circulation pipelines 5 is due to the series-connected thin-film constant-temperature liquid circulation pipelines 5 .

[0032] The second type, such as Figure 5 As shown, there are four film-shaped constant-temperature liquid circulation pipelines 5, which are respectively attached to the four sides of the base 2, and the four film-shaped constant-temperature liquid circulation pipelines 5 are connected in parallel to the supply liquid system, and,

[0033] The joints of any two sides are respectively set as the liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com