Method for determining coating rate of composite phase change material

A composite phase change material and a method for measuring the technology are applied in the field of measuring the coverage of composite phase change materials, which can solve the problems of complex testing methods, inability to obtain the coverage ratio of composite phase change materials truly and accurately, and high construction cost, and achieve the purpose of testing The effect of convenience and efficiency, reducing test costs and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

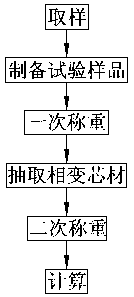

[0030] Such as Figure 1-2 As shown, a method for measuring the cladding rate of a composite phase change material is carried out as follows: Step 1: Sampling: Take the composite phase change material for testing, and record it as mass M0; Step 2: prepare a test sample: put Step 1 obtains the composite phase change material and presses it into a cylindrical shape, wraps the degreasing filter paper, and obtains the test sample 10; step 3: weigh once: weigh the test sample 10 obtained in step 2, and record it as the mass M1; step 4: extract the phase Change core material: adopt leaching method to remove the phase change core material in the test sample; step 5: secondary weighing: weigh the test sample 10 after processing in step 4, and record it as quality M2; step 6: calculate: use the formula (M1 -M2) / M0 to calculate the coating ratio of test sample 10.

[0031]A method for measuring the cladding ratio of a composite phase change material in this embodiment is to accurately ...

Embodiment 2

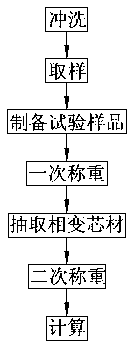

[0035] Such as Figure 1-3 As shown, a method for measuring the coverage of a composite phase change material in this embodiment, the test process is the same as in Example 1, the difference is that a pretreatment step is also provided before the step 1: rinse the composite phase change material, use To remove the phase change core material adhering to the surface of the composite phase change material.

[0036] A method for measuring the cladding rate of a composite phase change material in this embodiment is to repeatedly rinse the composite phase change material by setting a pretreatment step before step 1 to remove the phase change core material adhering to the surface of the composite phase change material, The results of the measured coating ratio all come from the phase change core material coated inside the composite phase change material, making the test results more accurate. In this embodiment, two sets of tests are preferably carried out at the same time, and one s...

Embodiment 3

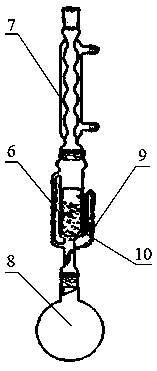

[0038] Such as Figure 1-6 As shown, a method for measuring the coverage of a composite phase change material in this embodiment, the test process is the same as that of Example 1, the difference is that the sample preparation mechanism includes a base 1, a sample preparation cylinder 2 and a stamping rod 3, The sample preparation chamber 21 is arranged in the sample preparation cylinder 2, and the ventilation chamber 22 adapted to the base 1 is also arranged in the sample preparation cylinder 2, and the ventilation chamber 22 communicates with the sample preparation chamber 21. The orifice plate 4 for separating the ventilation chamber 22 and the sample preparation chamber 21 is also arranged in the sample cylinder 2, and the orifice plate 4 is provided with a number of ventilation holes 41. On the basis of the sample preparation mechanism adopting this structure, the The above step 2 includes the following steps: Step 2.1: Assemble the components of the sample preparation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com