Rubber seal product life prediction method based on aging damage

A technology for life prediction and rubber products, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low accuracy, low accuracy, and variable calculation cannot be programmed, and achieve high prediction accuracy and prediction Wide temperature range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] by The fluorosilicone rubber O-ring is used as an example to illustrate the specific characterization process.

[0032] Obtain the highest test temperature T of the fluorosilicone rubber by thermogravimetric method max 200°C, 120°C, 150°C, and 180°C were used as the hot air aging test temperature, and the compression rate was 25% as the load condition. 20d, 25d, 30d, 45d, 55d.

[0033] The test sample is 15 pieces Type fluorosilicone rubber O-rings.

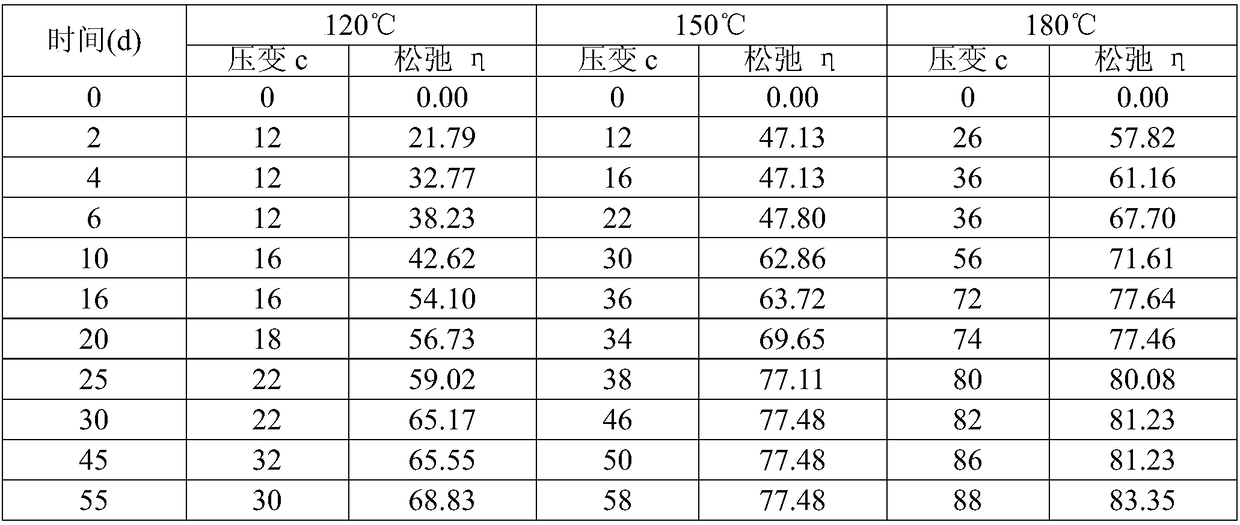

[0034] According to GB / T 2941-2006 method for state adjustment, GB / T 3512-2014 for accelerated aging by hot air; according to GB / T 1685-2008 and GB / T 7759.1-2015 for the determination of compressive stress relaxation and compression set. The test data are shown in Table 1.

[0035] Table 1 Fluorosilicone rubber O-ring hot air aging test results table

[0036]

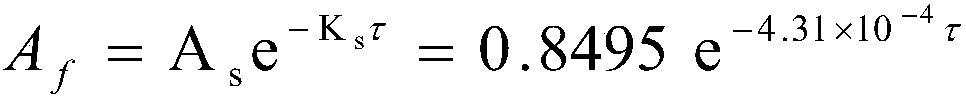

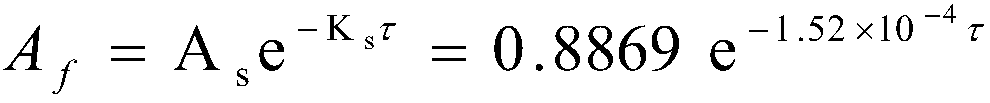

[0037] For the data in Table 1, according to the grey correlation degree calculation process, calculate the correlation degree g of the compressive stres...

Embodiment 2

[0052] by Type silicone rubber O-ring as an example to illustrate the specific characterization process as follows.

[0053] Obtain the highest test temperature T of the silicone rubber by thermogravimetric method max 200°C, 100°C, 125°C, 150°C, and 175°C are used as the hot air aging test temperature, and the compression rate is 25% as the load condition. The sampling period is 0d, 2d, 4d, 6d, 10d. , 16d, 20d, 25d, 30d, 45d, 55d.

[0054] The test sample is 20 pieces Type silicone rubber O-rings.

[0055] The laboratory environmental test and the construction method of the aging damage factor are the same as those in Example 1 (the original test data is omitted), and the A of the silicone rubber O-ring at different temperature points f The values are shown in Table 4.

[0056] Table 4 Life evaluation characteristic index A of silicone rubber O-rings at different temperature points f Value table

[0057] time(d)

100℃

125℃

150℃

175℃

0

0....

Embodiment 3

[0063] by The fluororubber O-ring is used as an example to illustrate the specific characterization process as follows.

[0064] Obtain the highest test temperature T of the fluororubber by thermogravimetric method max The temperature is 200°C, 100°C, 125°C, 150°C, and 175°C are used as the hot air aging test temperature, and the four compression ratios of 15%, 20%, 25%, and 30% are used as the load conditions to carry out the hot air aging test. The sampling period They are 0d, 1d, 3d, 7d, 10d, 15d, 20d, 25d, 30d, 35d, 40d, 60d, 75d, 90d, 110d, respectively.

[0065] The sampling cycle after combination according to the principle of "low temperature and high compression, high temperature and low compression" is shown in Table 5 below.

[0066] Table 5 Fluorine rubber accelerated life test sampling table

[0067]

[0068] The test sample is 40 pieces Fluorocarbon O-rings.

[0069] The laboratory environmental test is the same as in Example 1, and the correlation degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com