Condensate water testing device and testing method adopting same

A technology of a test device and a test method, applied in the field of sample testing, can solve the problems of the tested sample destroying the experimental results, the accuracy of the test results is not high, and the surface of the sample is not easy, so as to reduce the contact area and generate uniform and stable water vapor. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

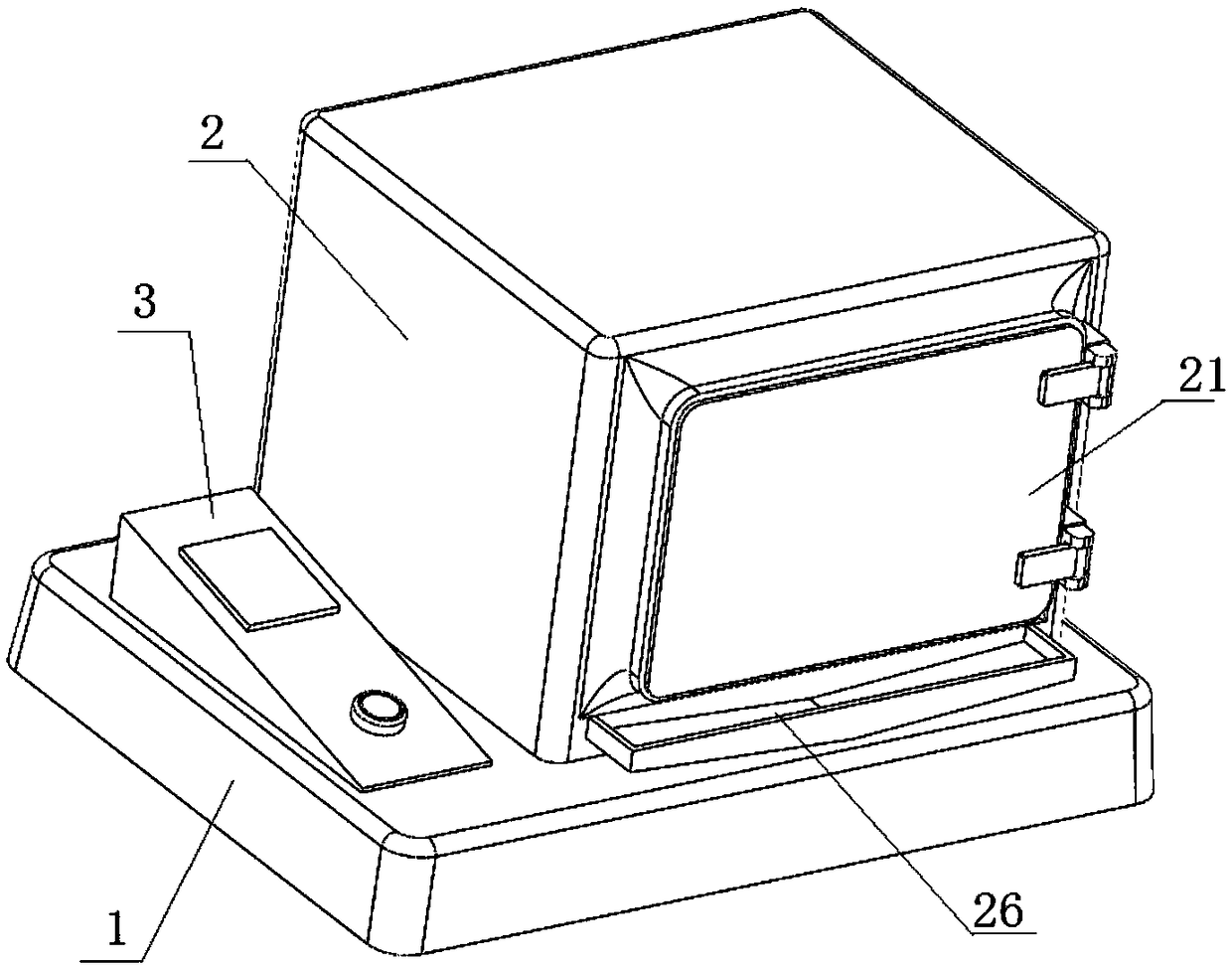

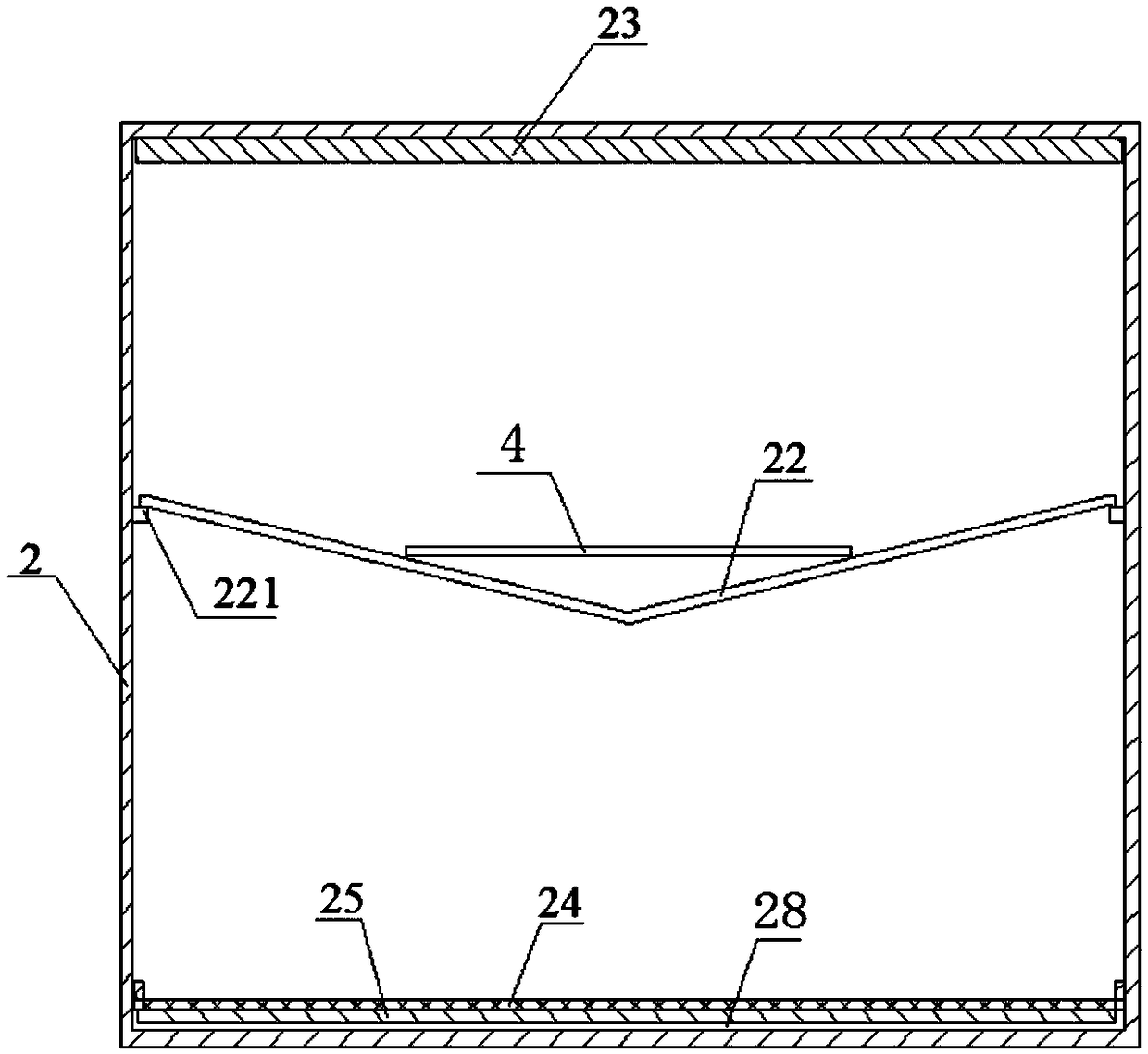

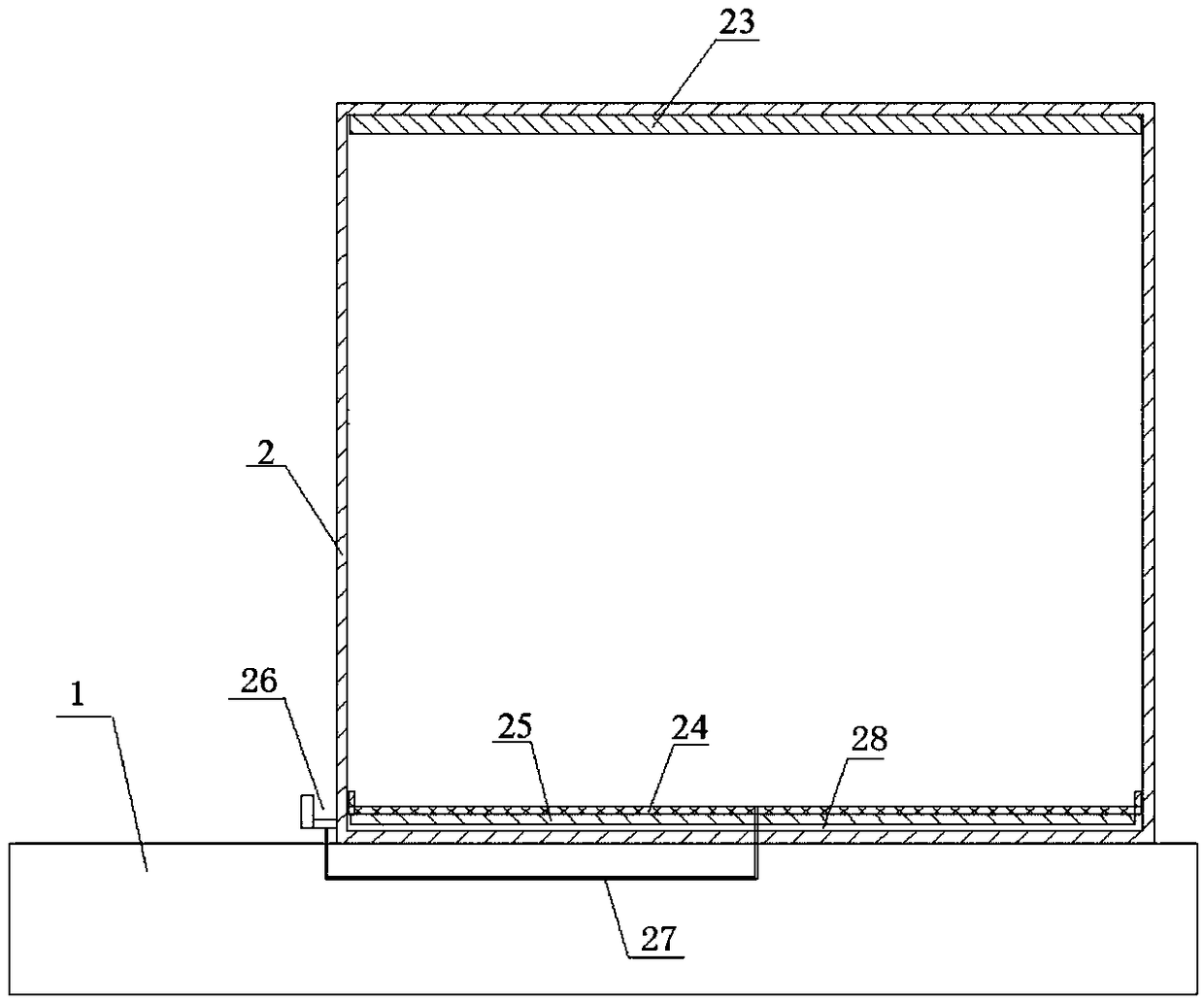

[0034] A condensate test device such as Figure 1~3 As shown, it includes an installation base 1, a test box 2 arranged on the installation base 1, and a digital display controller 3. A front side of the test box 2 is provided with a box door 21, and a detachable sample rack 22 is provided in the test box 2. The top of the test box 2 is pasted with an electric heating glass plate 23, the bottom is provided with a water tray 24 for holding water and a heater 25 for heating the water tray 24, and the top of the water tray 24 is provided with a digital display control panel. The temperature sensor and temperature-humidity sensor that device 3 communication is connected, the bottom of box door 21 is provided with water receiving tank 26, and water receiving tank 26 is connected with water tray 24 by U-shaped pipe 27, and the bottom of U-shaped pipe 27 is provided with drain valve. By installing an electric heating glass plate on the top of the test chamber, it can play the role of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com