Rockburst microseismic monitoring method for long-distance TBM tunnel under soft and hard interbedded geological conditions

A geological condition and microseismic monitoring technology, applied in seismology, geophysical measurement, seismic signal processing, etc., can solve problems such as poor signal acquisition quality, impact on rockburst continuity monitoring, line damage, etc., to reduce workload and ensure Continuity monitoring, effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

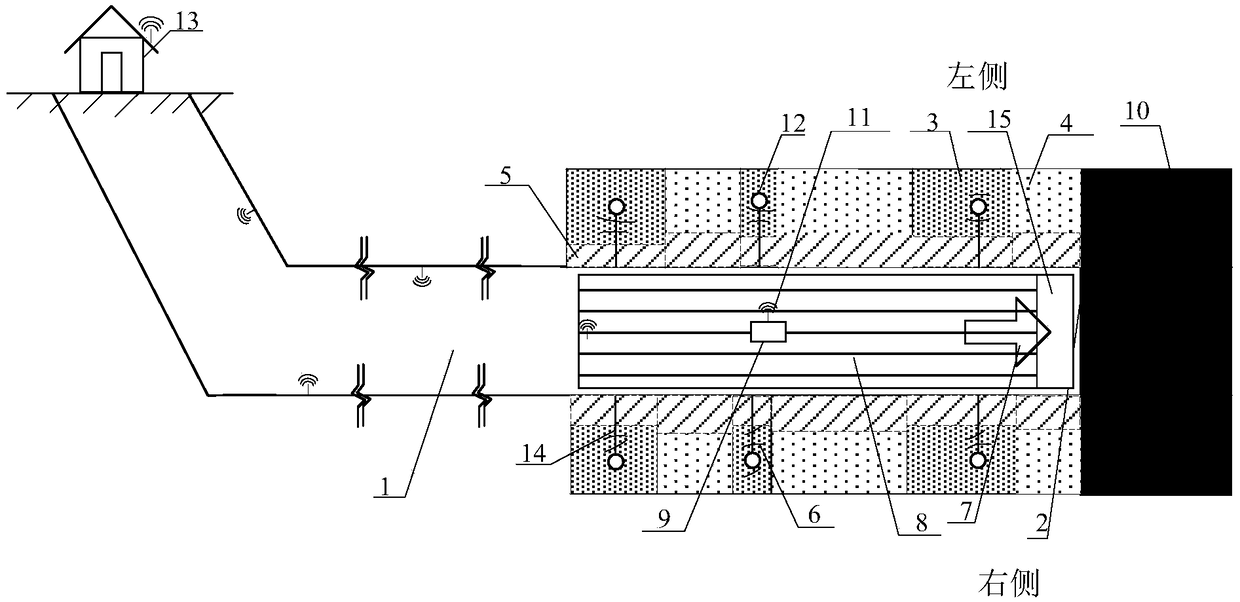

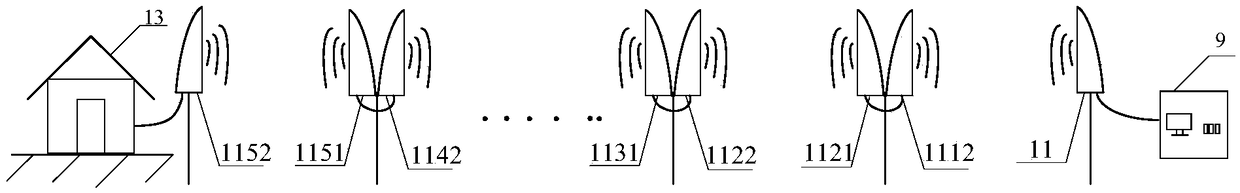

[0029] The diversion tunnel of a hydropower project is excavated by TBM, with a maximum buried depth of 1900m and a TBM tunnel length of 11.5km. It is a large-scale underground hydropower project with ultra-deep buried long tunnels. In the engineering area, hard rock sandstone, hard rock siltstone and soft rock mudstone are interbedded, and the strike of the rock strata intersects the axis of the tunnel at a large angle, showing a continuous distribution and development law. Rockburst microseismic monitoring is carried out in the long-distance TBM tunnel under the soft and hard interbedded geological conditions. The microseismic monitoring method is as follows.

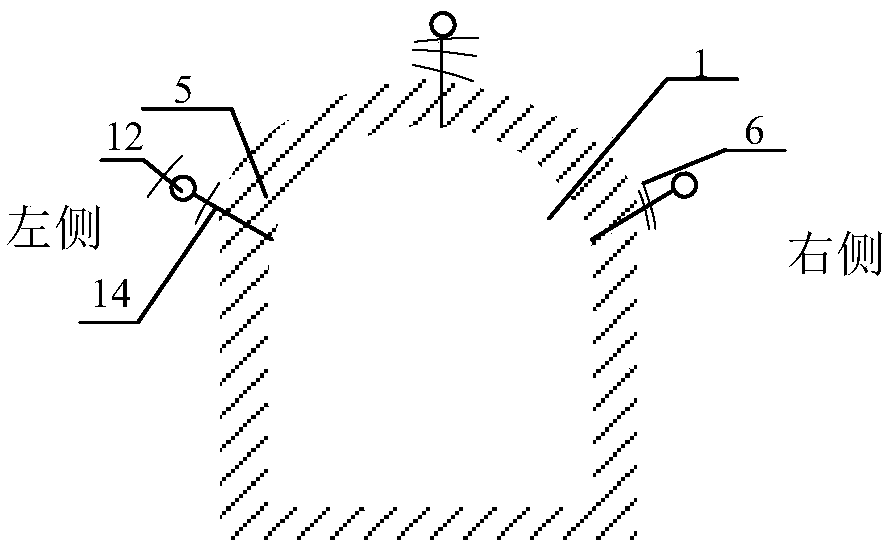

[0030] Geological survey found mudstone and sandstone within 17m behind TBM face 2, of which the mudstone cave section is 3m long and the sandstone section is 14m long. Under the premise of comprehensively considering the rock mass quality and monitoring distance, the microseismic sensor 12 is arranged at the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com