Liquid crystal touch screen and manufacturing method thereof

A manufacturing method and touch screen technology, applied in the fields of optics, instruments, electrical digital data processing, etc., can solve the problems of touch screen 22 thickness, high cost, etc., and achieve the effect of increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

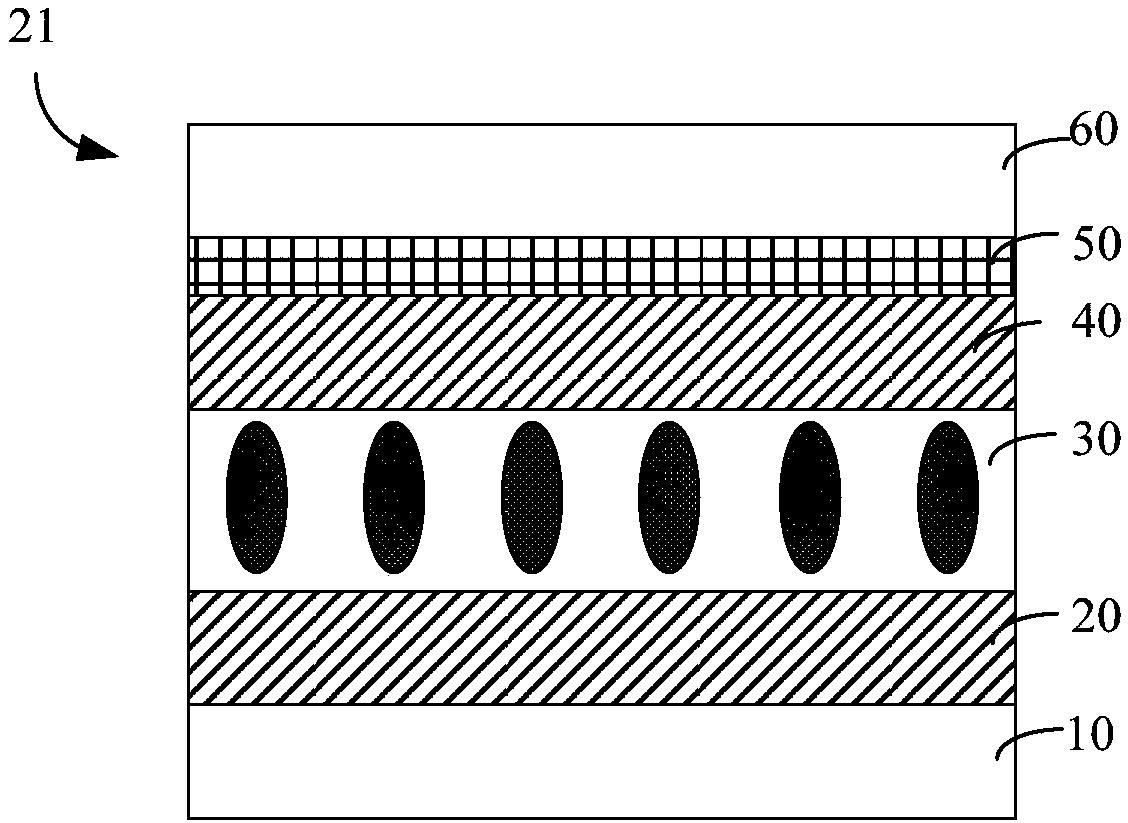

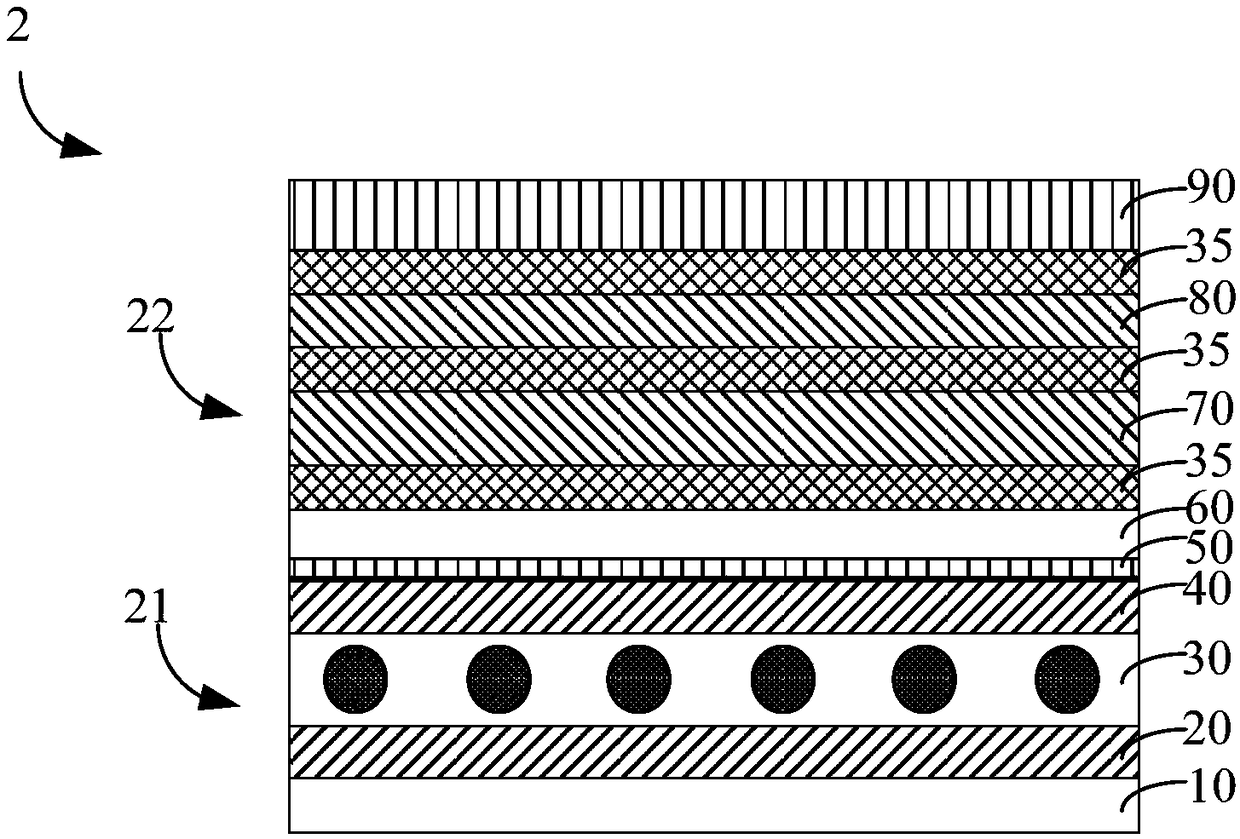

[0044] refer to Figure 4 , which is a schematic structural diagram of the liquid crystal touch screen 1 according to an embodiment of the present invention.

[0045] Such as Figure 4 As shown, one aspect of the present invention provides a liquid crystal touch screen 1 : it includes: a liquid crystal screen 100 and a touch screen 200 . The liquid crystal screen 100 includes: a first polarizer 110; a first glass substrate 120 disposed on the first polarizer 110; a liquid crystal layer 130 disposed on the glass substrate 120; a second glass A substrate 140 is disposed on the liquid crystal layer 130 ; and a color filter 150 is disposed on the second glass substrate 140 .

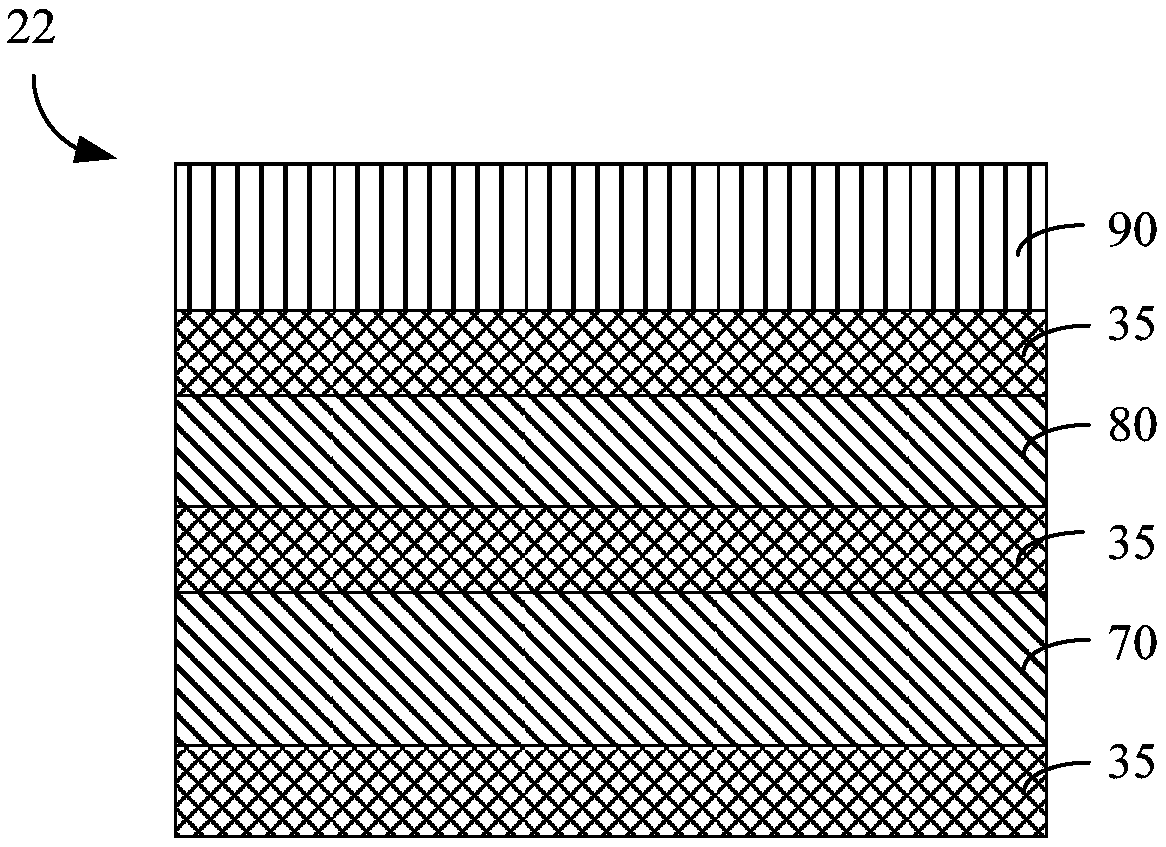

[0046] The touch screen 200 includes: a first conductive electrode layer 210; a second conductive electrode layer 220 disposed on the first conductive electrode layer 210; and a second polarizer 230 disposed on the first conductive electrode layer 220 on the second conductive electrode layer.

[0047] Ge...

Embodiment 2

[0053] refer to Figure 5 , which is a flowchart of a method for manufacturing a liquid crystal touch screen according to an embodiment of the present invention.

[0054] Such as Figure 5 As shown, one aspect of the present invention provides a method for manufacturing a liquid crystal touch screen, comprising the following steps:

[0055] Step S10: providing a first polarizer 110;

[0056] Step S20: setting a first glass substrate 120 on the first polarizer 110;

[0057] Step S30: setting a liquid crystal layer 130 on the glass substrate 120;

[0058] Step S40: setting a second glass substrate 140 on the liquid crystal layer 130;

[0059] Step S50: setting a color filter 150 on the second glass substrate 140;

[0060] Step S60: setting a first conductive electrode layer 210 on the color filter 150;

[0061] Step S70: disposing a second conductive electrode layer 220 on the first conductive electrode layer 210; and

[0062] Step S80: setting a second polarizer 230 on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap